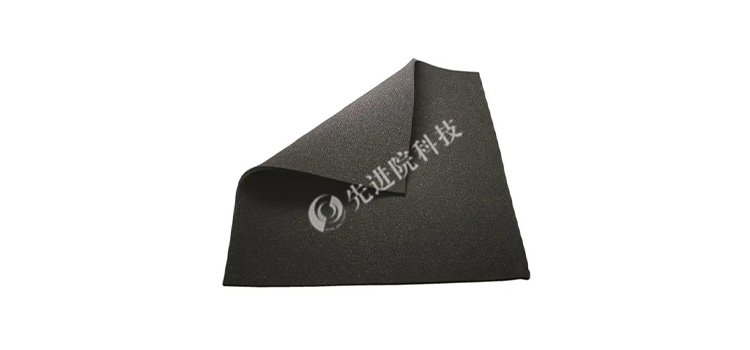

Composition materials

- Matrix material: the main matrix of hard foam absorbing material is light foam plastic, such as polyurethane (PU). These materials have characteristics such as low density and high flexibility, providing excellent structural support for composite materials.

- Absorbents: In order to endow materials with absorbing properties, various absorbents such as ferrite powder, carbonyl iron powder, conductive particles, etc. are usually added to the matrix material. These absorbers can effectively convert electromagnetic wave energy into thermal energy or other forms of energy, thereby achieving the absorption effect.

Main characteristics

- Light weight and high efficiency: hard foam absorbing material combines the lightness of foam materials and the electromagnetic wave absorption characteristics of absorbing materials, with the advantages of light weight and high absorbing efficiency. This helps to reduce equipment weight and improve overall performance.

- Tight structure: by controlling the chemical reaction in the foaming process, the hard foam absorbing material can form a more uniform and stable cell structure, thus improving its wave absorption effect and mechanical strength.

- Strong durability: hard foam provides good compression resistance and elasticity for the material, making hard foam microwave absorbing material have a long service life.

- Good flame retardancy: some rigid foam absorbing materials also have excellent flame retardancy, which can prevent fire to a certain extent.

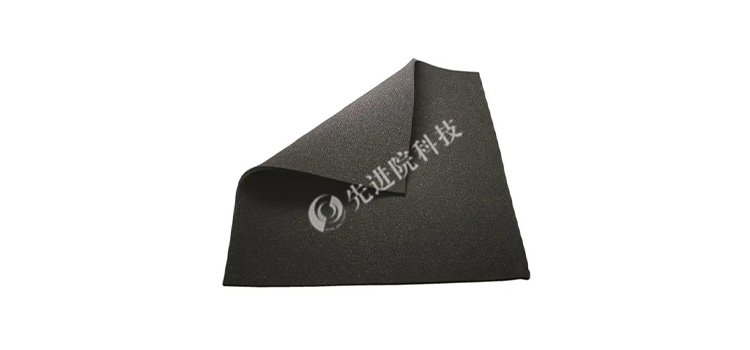

Working principle

The working principle of hard foam absorbing materials is mainly based on the loss mechanism of electromagnetic waves. When electromagnetic waves are incident on the surface of a material, some of the waves are reflected and some enter the interior of the material. Inside the material, electromagnetic waves interact with absorbers, causing the energy of electromagnetic waves to be converted into thermal energy or other forms of energy and dissipated. By adjusting the formulation of materials, process parameters, and types of hardeners, optimization and control of electromagnetic wave absorption performance can be achieved.

application area

Hard foam absorbing materials are widely used in many fields due to their excellent performance characteristics:

- Aerospace: Used to reduce the noise and vibration of aircraft and spacecraft during flight and launch, improve flight safety and spacecraft performance stability. At the same time, it can also reduce the radar cross section and improve stealth performance.

- Military: Applied in weapons and equipment such as missiles, tanks, and ships, it can effectively weaken its own characteristic signals, reduce the reflection of external electromagnetic waves, light waves, and infrared rays, and achieve anti radar reconnaissance.

- Electronic communication: used as electromagnetic shielding material in base stations, antennas and other equipment to reduce electromagnetic interference and improve communication quality.

- Automobile: Used to reduce noise pollution such as engine noise, road noise, and wind noise, while protecting the body and roof from external damage.

- Architecture: Applied in places such as theaters, recording studios, and cinemas that require high-quality acoustic effects, it can reduce noise and vibration inside buildings and improve acoustic effects.