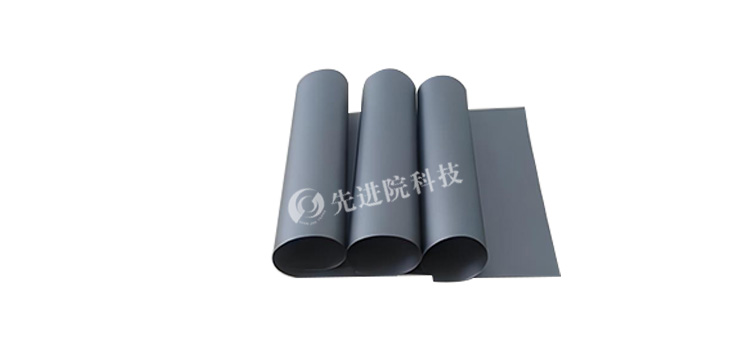

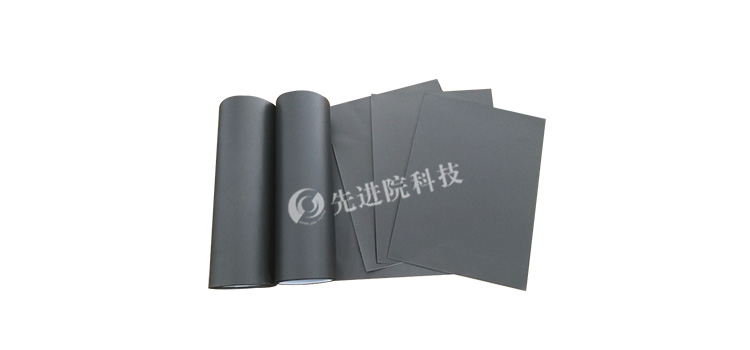

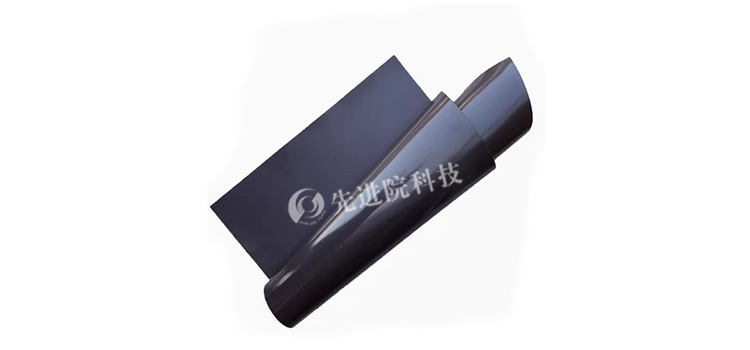

Rubber patch type absorbing material is a composite material that combines rubber substrate with absorbing agents (such as iron-based materials, conductive particles, etc.), and has excellent electromagnetic wave absorption performance.

Material composition and characteristics

1. Composition materials

- Rubber substrate: Rubber substrate endows the material with good flexibility and mechanical strength, enabling it to adapt to various complex shapes and installation environments. Common rubber substrates include silicone rubber, chloroprene rubber, etc.

- Absorbent: Absorbent is a key component for materials to achieve electromagnetic wave absorption, usually including ferrite powder, carbonyl iron powder, conductive particles, etc. These absorbers can effectively convert electromagnetic wave energy into thermal energy or other forms of energy, thereby reducing the reflection and transmission of electromagnetic waves.

2. Main characteristics

- Efficient absorption: Rubber patch type absorbing materials have efficient electromagnetic wave absorption capabilities in specific frequency bands, which can effectively reduce electromagnetic radiation and interference.

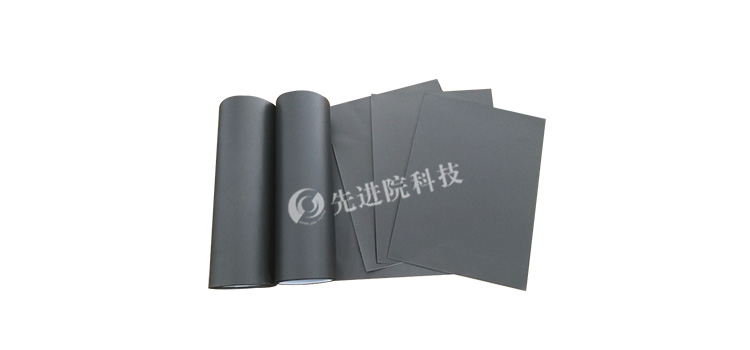

- Thin and flexible: The material has a thin thickness and good flexibility, making it easy to install and use on various devices.

- Strong durability: It has good weather resistance and corrosion resistance, and can maintain stable performance for a long time in harsh environments.

- Controllable process: By selecting different substrates and absorbers, as well as adjusting the formulation and process parameters of materials, the optimization and control of material properties can be achieved.

application area

Rubber patch type absorbing materials are widely used in various fields that need to solve electromagnetic wave interference problems, including:

- Electronic devices: used to suppress internal electromagnetic interference and external electromagnetic radiation, improve device performance and reliability.

- Communication equipment: prevents leakage and interference of electromagnetic waves, and improves the transmission quality of communication signals.

- Radar system: Reduce the reflected waves generated by radar equipment and enhance the detection capability of the radar.

- Aerospace: Used for electromagnetic shielding and stealth technology to reduce the visibility of aircraft under radar detection.

- Automotive industry: Reduce the reflection and scattering of electromagnetic waves by the vehicle body, and improve the performance of in vehicle systems.

Selection and Design

When selecting and designing rubber patch type absorbing materials, the following factors need to be considered:

- Frequency range: Determine the required frequency range based on specific application scenarios.

- Absorption performance: Evaluate key performance indicators such as absorption rate and reflectivity of materials.

- Thickness and size: Determine the thickness and size of the material based on the installation space and usage requirements of the equipment.

- Durability: Consider the performance requirements of materials such as weather resistance and corrosion resistance in specific environments.

- Cost effectiveness: Reasonably control costs while ensuring performance.