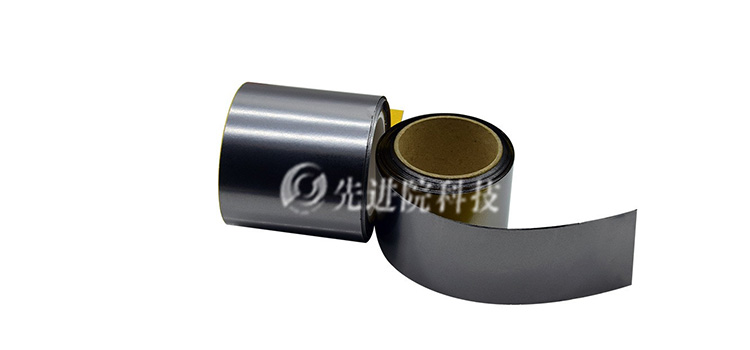

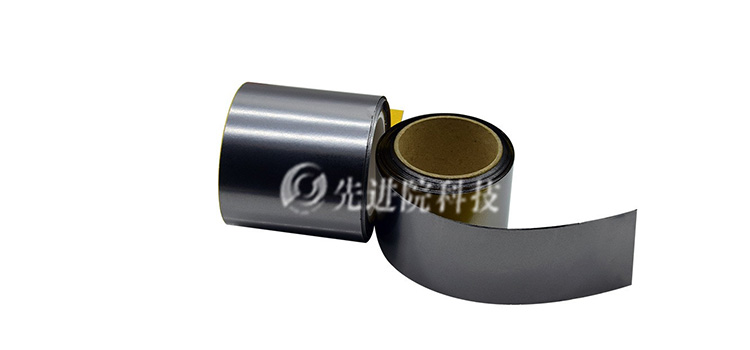

The nanocrystalline magnetic separator is composed of a copper foil and several layers of organic tape stacked together, containing tiny ferromagnetic material nanocrystals inside. This special structure enables the nanocrystalline magnetic separator to act as a magnetic barrier, preventing mutual interference in the circuit.

Main characteristics

- High magnetic permeability: Nanocrystalline magnetic separators have high magnetic permeability, which can effectively guide magnetic fields, reduce magnetic field leakage and interference.

- Low loss: By optimizing materials and structures, nanocrystalline magnetic separators can reduce eddy current losses and improve charging efficiency.

- Ultra thin design: The nanocrystalline magnetic separator has the characteristic of being ultra-thin, with a minimum thickness of up to 30 microns, and the size and thickness can be customized according to customer needs.

- Flexible material: The nanocrystalline magnetic separator is made of flexible material, effectively avoiding the breakage and leakage of the magnetic separator, and facilitating operation.

- Multifunctionality: The nanocrystalline magnetic separator simultaneously meets the three functions of WPC (Wireless Charging Alliance), MST (Magnetic Secure Transmission), and NFC (Near Field Communication) without interfering with each other.

application area

- Electronic products: Nanocrystalline magnetic separators have been widely used in electronic products such as televisions, mobile phones, computers, etc. There are many circuits in these products, and magnetic separators can ensure that these circuits do not interfere with each other, thereby improving the performance and reliability of electronic products.

- Automotive industry: In modern automobiles, nanocrystalline magnetic separators have also been widely used. These magnetic separators can be placed on the circuit board of a car, avoiding mutual interference between circuits and improving the safety and stability of the car.

- In the industrial field, nanocrystalline magnetic separators are also widely used, especially when large electronic devices are used in factories. Magnetic separators can reduce interference and sudden changes in current between devices, ensure the normal operation of equipment, and improve the production efficiency of factories.

Manufacturing process and requirements

The manufacturing process of nanocrystalline magnetic separators includes several procedures such as heat treatment, film lamination, demagnetization, and die-cutting. Due to the need to install it in smart devices, there will be very strict requirements for its thickness and accuracy. During the manufacturing process, there may be burr like residues on the edges of the product. It is necessary to introduce a visual system to accurately identify the location of the burrs and guide the laser process to remove the residual burrs to ensure the overall performance of the product.