High power conical honeycomb absorbing material is a special type of absorbing material designed and applied to efficiently absorb electromagnetic wave energy, especially exhibiting excellent performance in high-power environments. The following is a detailed analysis of this material:

Material characteristics

-

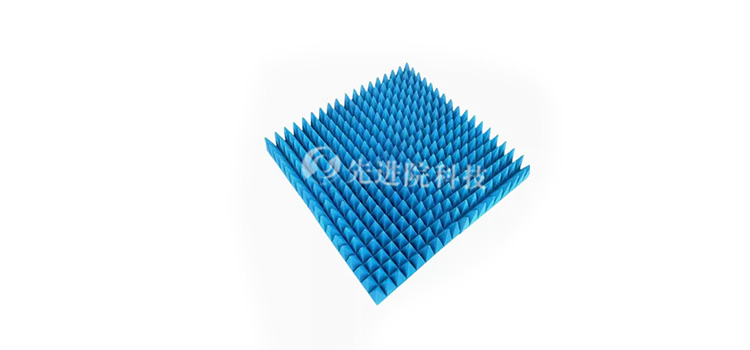

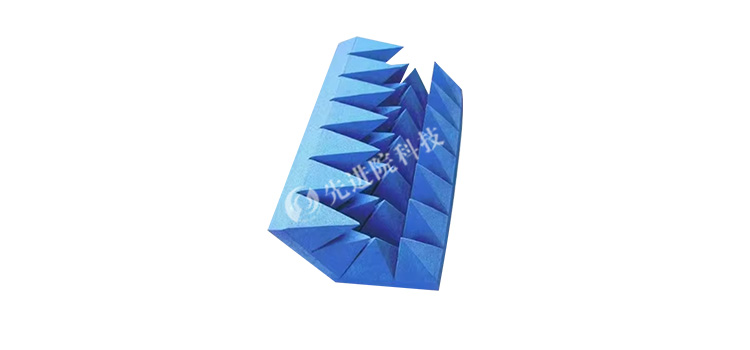

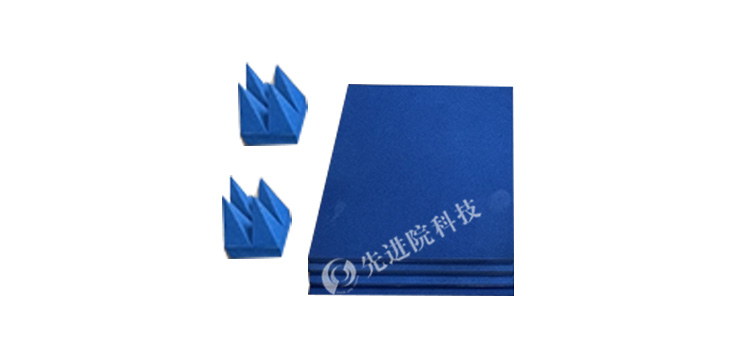

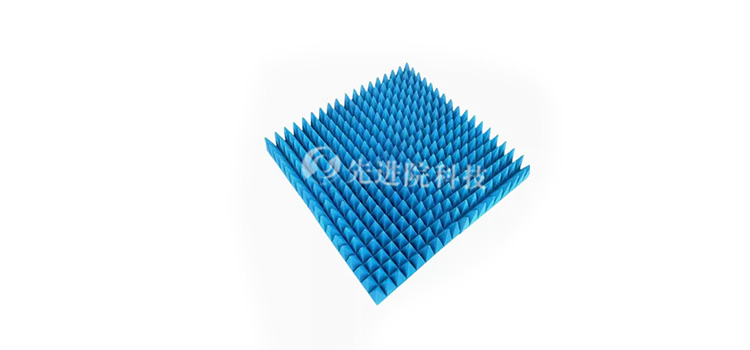

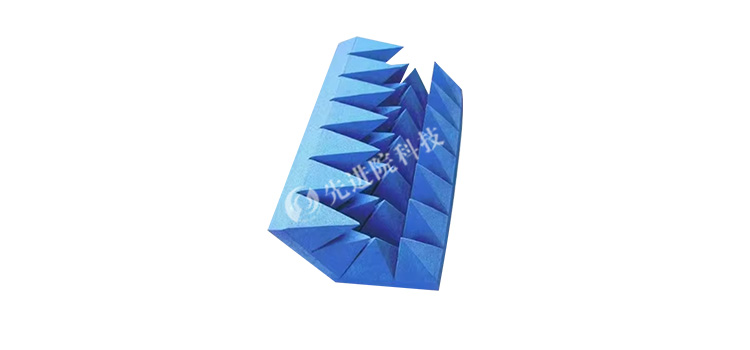

Structural characteristics:

- This material adopts a pyramid shaped honeycomb structure, which helps electromagnetic waves to undergo multiple reflections between cones, thereby increasing the loss and attenuation of electromagnetic waves inside the material.

- Air can circulate freely and improve heat dissipation efficiency through natural convection or forced ventilation.

-

Material composition:

- The main honeycomb structure usually uses lightweight and high-strength materials, such as aluminum, aramid paper, etc.

- Absorbents are often made of carbon based materials (such as carbon black, carbon fiber), ferrites, etc., which have excellent electromagnetic loss properties.

-

Temperature resistance and flame retardancy:

- High power conical honeycomb absorbing materials can withstand temperatures up to 176 ℃ and have high flame retardant properties.

-

Other performance:

- This material also has good flexibility, stability, and weather resistance, and can operate stably under various environmental conditions.

application area

High power conical honeycomb absorbing materials are widely used in the following fields due to their excellent absorption performance and stability:

- High energy areas of microwave anechoic chambers and equipment: In these areas, efficient absorption of electromagnetic waves is required to reduce reflection and interference, improve testing accuracy and performance.

- Radar or communication system antenna: used for absorption processing around the antenna to reduce electromagnetic wave leakage and interference, improve communication quality and stability.

Manufacturing and Material Selection

-

Material selection:

- When manufacturing high-power conical honeycomb absorbing materials, it is necessary to carefully select the main material and absorbing agent. The main material should have the characteristics of high strength, light weight, and easy processing; And absorbers should have excellent electromagnetic loss performance and stability.

-

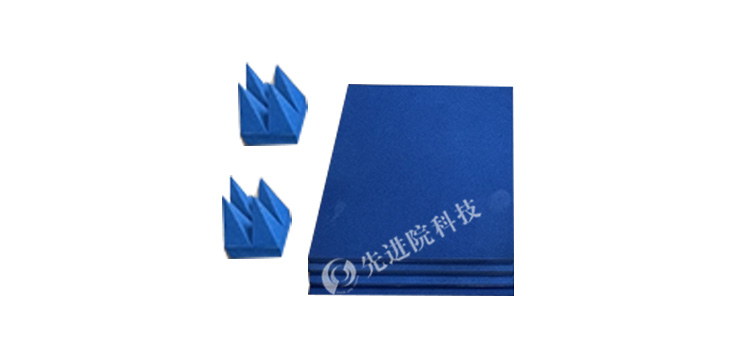

Manufacturing process:

- The manufacturing process involves integrating the absorber with the honeycomb structure through immersion, coating, and other methods, followed by drying, curing, and other process steps. During the manufacturing process, it is necessary to strictly control the content and distribution of the absorbing agent to ensure that the material's absorbing performance reaches its optimal state.