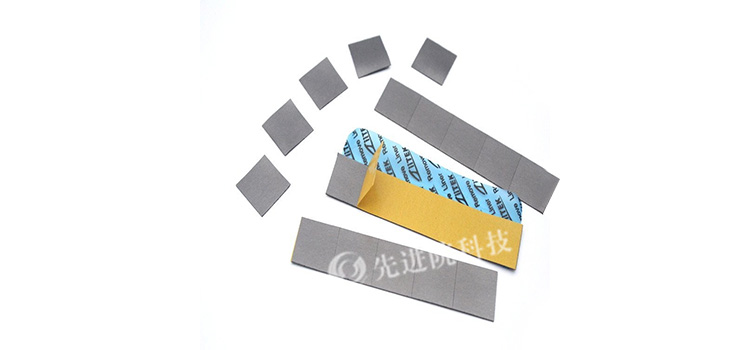

Low frequency absorbing materials refer to materials designed to absorb or attenuate low-frequency electromagnetic waves. This type of material is usually applied in situations where low-frequency electromagnetic wave interference needs to be suppressed, such as in power equipment, household appliances, communication systems, etc., to reduce electromagnetic interference (EMI) and improve equipment performance. Low frequency typically refers to electromagnetic waves with frequencies below 300kHz, but in some applications, it can also include frequencies up to several megahertz.

characteristic

- Absorption performance: These materials are capable of absorbing rather than reflecting electromagnetic waves, thereby reducing interference.

- Conductivity: Some low-frequency absorbing materials have a certain degree of conductivity and can absorb electromagnetic waves through eddy current effects.

- Mechanical performance: It usually has good mechanical strength and durability, and can work stably in different environments for a long time.

- Environmental adaptability: able to maintain its performance over a wide temperature range.

consist of

Low frequency absorbing materials may include the following components:

- Magnetic materials, such as ferrites and magnetic alloys, can absorb electromagnetic energy through hysteresis loss.

- Conductive materials, such as carbon fiber, graphite, etc., absorb electromagnetic waves through their conductive properties.

- Polymer matrix: As a carrier material, magnetic or conductive materials are uniformly distributed to form composite materials with absorbing properties.

Application scenarios

- Power equipment: Used in power equipment such as transformers and motors to reduce low-frequency electromagnetic interference.

- Household appliances: Used in appliances such as microwave ovens and induction cookers to reduce the impact of electromagnetic leakage on human health.

- Communication system: Used in communication equipment such as cables and connectors to reduce electromagnetic interference during signal transmission.

- Automotive electronics: Used in electronic devices inside cars to reduce electromagnetic noise generated by engines and other electrical components.

- Medical equipment: Used in medical devices such as MRI machines to reduce the impact of external electromagnetic interference on diagnostic results.

The benefits of using low-frequency absorbing materials

- Improving equipment performance: By reducing electromagnetic interference, the stability and reliability of the equipment can be enhanced.

- Protecting human health: reducing the potential harm of low-frequency electromagnetic waves to human health.

- Meet regulatory requirements: Help products comply with relevant electromagnetic compatibility (EMC) standards and regulatory requirements.