Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

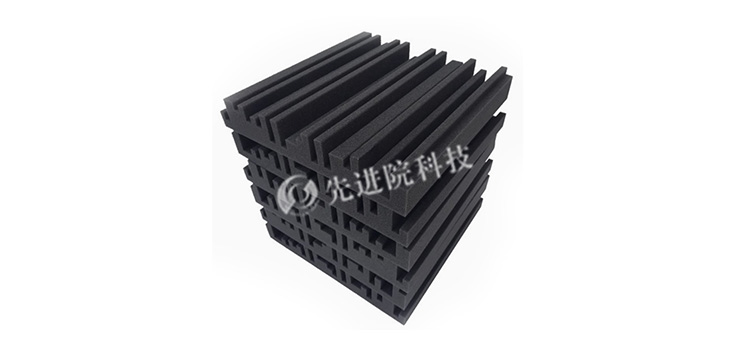

Leading the new trend of wave absorbing materials, the curly foam wave absorbing materials developed by the Advanced Institute (Shenzhen) Technology Co., Ltd., with its unique curly structure design, enhance the wave absorbing efficiency and stability. Lightweight, flexible, and easy to install and transport, it is the preferred material for mobile communication base stations, ships, and other fields. Choose us and create a non interfering electromagnetic environment together! Advanced Institute of TechnologyCurly foam absorbing material, can be customized according to needs; Welcome to consult.

+86-13826586185

Curly foam absorbing material is a kind of porous material prepared by a specific process. Its foam structure presents a curly geometric shape, such as "egg shaped" or other irregular shapes. This design aims to enhance the material's absorption of electromagnetic waves. Materials are typically composed of conductive or magnetic fillers and polymer matrices.

With the continuous progress of material science and engineering technology, crimp foam absorbing materials will develop towards higher performance, lower cost and wider application. The future crimped foam absorbing materials may have the following development directions:

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2