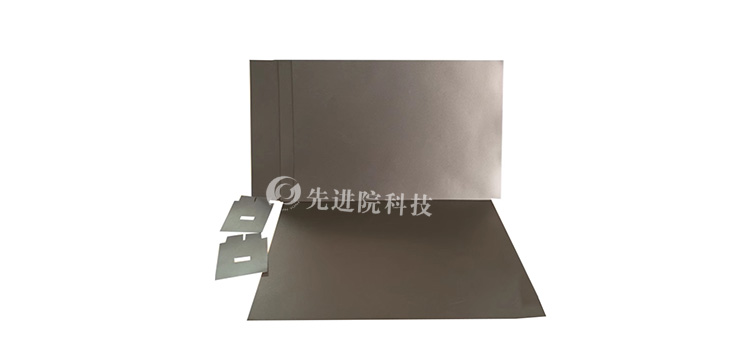

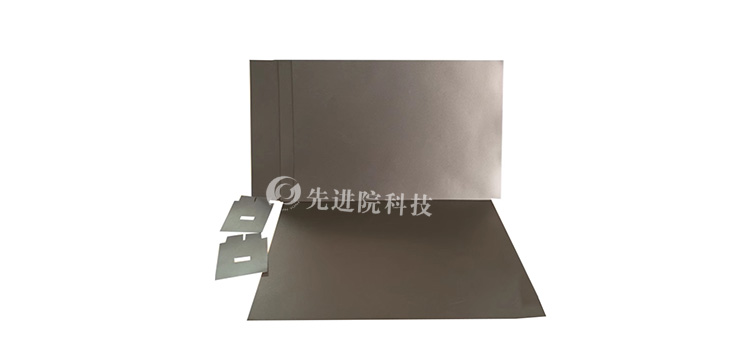

High permeability absorbing material is a material that absorbs electromagnetic waves through its high permeability characteristics. This type of material mainly relies on magnetic loss mechanism to absorb electromagnetic waves, and is widely used in fields such as electromagnetic compatibility (EMC), electromagnetic interference (EMI) protection, stealth technology, and environmental protection.

Main performance characteristics

- High magnetic permeability: It has a high magnetic permeability and can generate magnetic losses over a wide frequency range, thereby absorbing electromagnetic waves.

- Broadband absorption: By optimizing the composition and structure of materials, wideband electromagnetic wave absorption is achieved.

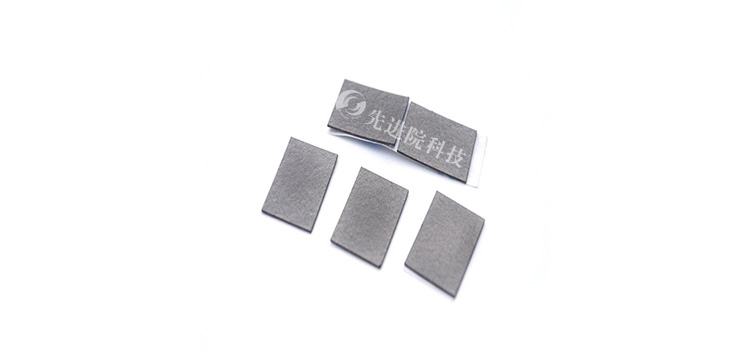

- Lightweight: Typically lightweight and suitable for applications with strict weight requirements.

- Flexibility: Many high permeability absorbing materials have good flexibility and processability, suitable for surfaces of various complex shapes.

- Environmental resistance: It has good temperature resistance, moisture resistance, corrosion resistance and other properties, and is suitable for various harsh environments.

Commonly used high permeability absorbing materials

- Ferrite materials, such as spinel type ferrites (such as MgFe ₂ O ₄, NiZnFe ₂ O ₄) and garnet type ferrites (such as YIG), have excellent magnetic loss properties.

- Carbonyl iron powder: has high magnetic permeability and magnetic loss performance.

- Nickel zinc ferrite: has good magnetic loss performance and wideband absorption characteristics.

- Cobalt based ferrite: has high magnetic permeability and magnetic loss performance.

- Nano magnetic materials, such as nano iron powder, nano cobalt powder, etc., have higher specific surface area and better magnetic loss performance.

Matrix material

- Polymer matrix, such as polyurethane (PU), polyethylene (PE), polypropylene (PP), etc., has good flexibility and processability.

- Rubber matrix, such as natural rubber, nitrile rubber (NBR), chloroprene rubber (CR), etc., has good chemical stability and dielectric loss performance.

- Thermoplastic materials, such as polycarbonate (PC), polyamide (PA), etc., have good mechanical properties and environmental resistance.

Preparation process

- Mixing method: Mix magnetic materials with matrix materials and evenly disperse them through mechanical stirring, ultrasonic dispersion, and other methods.

- Sol gel method: the ferrite material with high permeability is prepared by the sol gel method, and then it is compounded with the matrix material.

- Electrospinning method: Nanofibers with high specific surface area are prepared by electrospinning method and then composite with matrix material.

- Chemical Vapor Deposition (CVD): Nano magnetic materials are prepared by chemical vapor deposition and then composite with the substrate material.

- Hot pressing method: The mixed materials are subjected to hot pressing treatment at a certain temperature and pressure to form uniform thin films.

- Coating method: A suspension of magnetic material is coated onto a substrate material, and then dried and cured to form an absorbing material.

application area

- Electromagnetic compatibility: In electronic devices, it is used to reduce electromagnetic interference and improve the electromagnetic compatibility of the equipment.

- Stealth technology: used to manufacture stealth aircraft, ships and other equipment, reduce radar wave reflection, and improve stealth performance.

- Wireless communication: In antenna design, it is used to improve the radiation performance of antennas and enhance signal transmission quality.

- Environmental Protection: Used to reduce electromagnetic pollution, protect the environment and human health.

- Aerospace: Used to manufacture absorbing coatings for aircraft and spacecraft, improving the stealth performance of aircraft.

- Automotive industry: Used to manufacture absorbing materials for automobiles, reduce electromagnetic interference inside the car, and improve driving safety and comfort.