Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

+86-13826586185

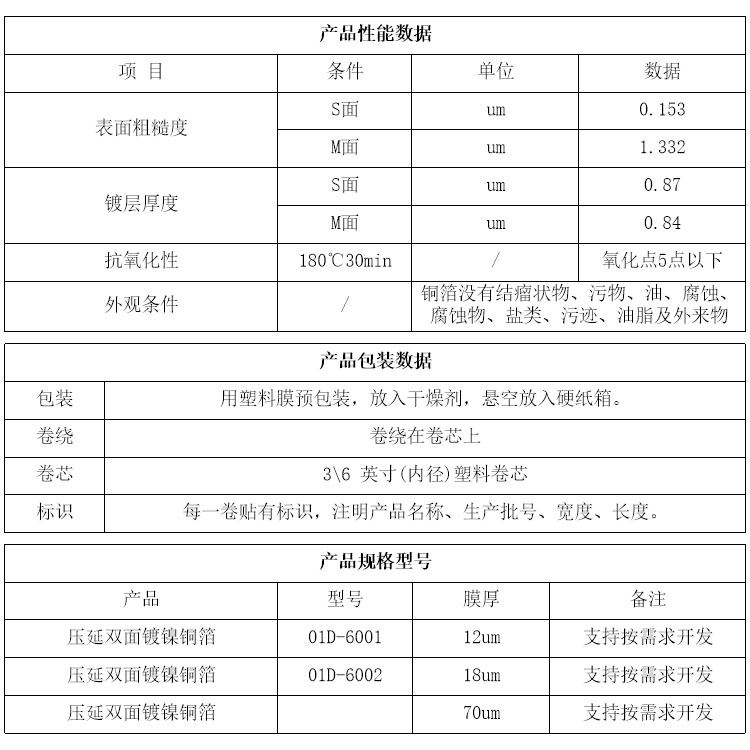

Rolled double-sided nickel plated copper foil is a high-performance composite material made by uniformly coating both sides of the rolled copper foil with a layer of nickel metal. This product not only retains the excellent conductivity and ductility of copper foil, but also significantly improves its corrosion resistance, wear resistance, and aesthetics, thus meeting the application needs of more high-end fields.

Product characteristics

Excellent conductivity: Rolled copper foil itself has good conductivity, and double-sided nickel plating further ensures the stability of its conductivity, making it suitable for high-frequency transmission and the manufacturing of precision electronic devices.

Excellent corrosion resistance: The nickel coating provides an effective protective barrier for copper foil, which can resist the erosion of corrosive substances such as acid, alkali, salt, etc., extending the service life of the product.

Good machinability and formability: The surface of the rolled double-sided nickel plated copper foil is flat and smooth, making it easy for subsequent mechanical processing and forming treatment, meeting the requirements of complex processes.

High hardness and wear resistance: Nickel plating increases the surface hardness of copper foil, giving it better wear resistance and maintaining stable performance in harsh working environments.

Aesthetic appearance: The nickel plated copper foil surface presents a uniform and bright metallic luster, enhancing the overall aesthetic of the product.

Production process

Preparation of Rolled Copper Foil: High purity copper is selected as the raw material and processed through rolling technology to produce copper foil with the required thickness and width.

Surface pretreatment: Clean, remove dirt, and oil from the surface of copper foil to ensure good adhesion between the coating and the copper foil substrate.

Nickel plating treatment: Using electroplating or chemical plating methods, a layer of nickel metal is uniformly plated on both sides of the copper foil. The electroplating process requires precise control of parameters such as current, voltage, and plating solution composition to ensure the uniformity and quality of the coating.

Post treatment: Clean and dry the nickel plated copper foil to remove residual chemical reagents and moisture, and perform necessary surface treatment to improve its performance.

workshop show

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2