Carbon fiber is an advanced material with high strength and lightweight, which is made by thermal decomposition of polyacrylonitrile (PAN), asphalt, or synthetic fibers at high temperatures. Carbon fiber is renowned for its excellent mechanical properties, low density, high modulus, high temperature resistance, and corrosion resistance, and is widely used in various fields such as aerospace, automotive, sports equipment, and building reinforcement.

Material characteristics

Carbon fiber filaments have the following characteristics:

- High strength: Compared to steel, carbon fiber has higher strength and lighter weight.

- Lightweight: With a density of about one fourth that of steel, carbon fiber is an ideal choice for reducing weight.

- High modulus: It has a high elastic modulus, which means it is not easily deformed when subjected to stress.

- High temperature resistance: able to maintain its structural stability and strength at higher temperatures.

- Corrosion resistance: It has good resistance to most chemicals.

- Non magnetic: not attracted by magnetic fields, suitable for applications that require avoidance of magnetic interference.

production process

The production of carbon fiber usually includes the following steps:

- Preparation: First, spin polyacrylonitrile (PAN) or other precursor materials into silk.

- Oxidation: Heating the fiber bundle in a controlled atmosphere to undergo an oxidation reaction, forming an intermediate phase.

- Carbonization: Further heating the intermediate phase fiber bundle and converting it into carbon fibers in an inert gas environment.

- Surface Treatment and Scaling: In order to improve the processability of carbon fibers, the fiber surface is treated and a sizing agent is applied.

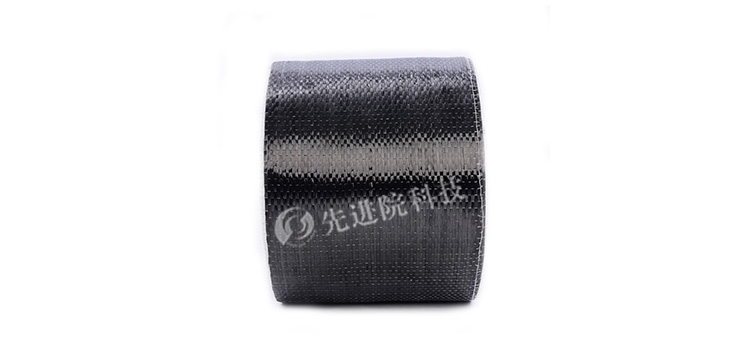

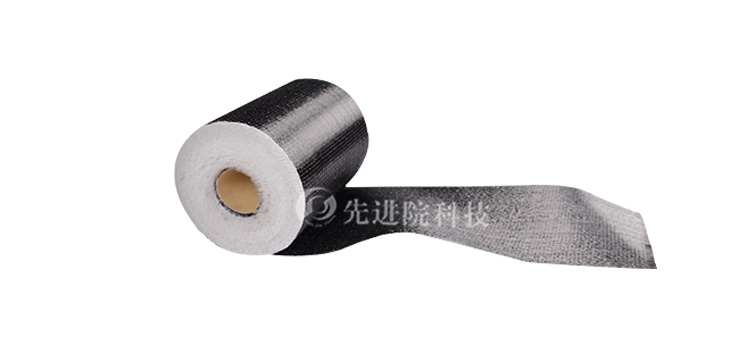

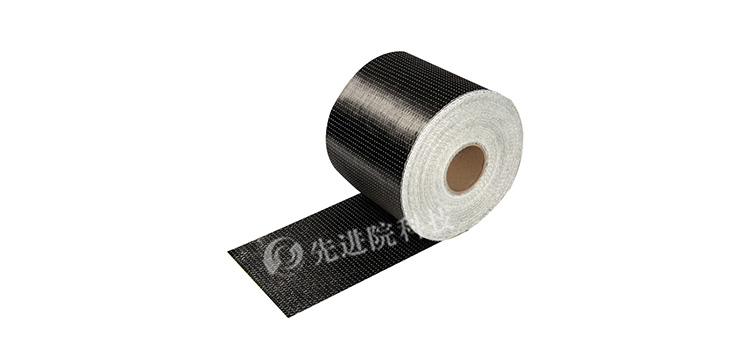

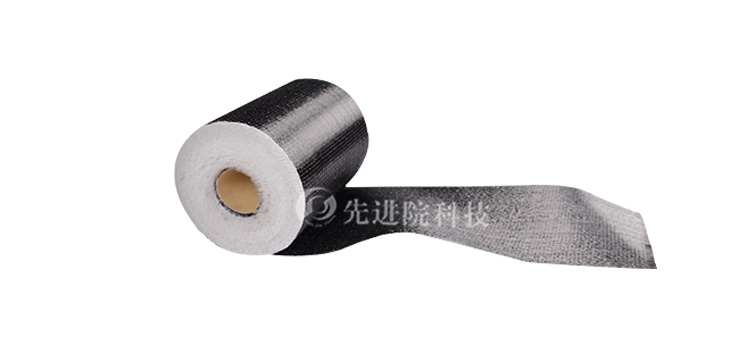

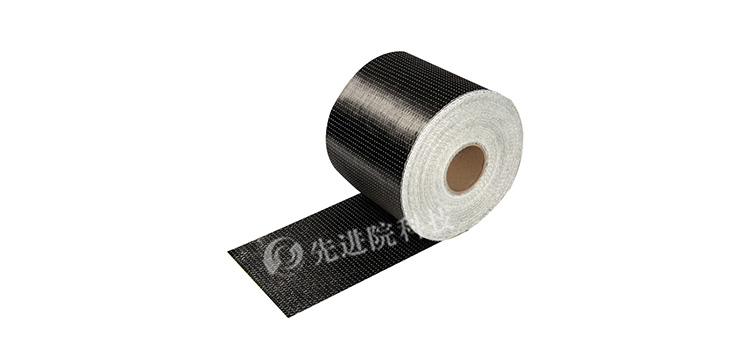

- Winding: Finally, the carbon fiber filament is wound into a roll for subsequent use.

application area

Due to its unique properties, carbon fiber filaments are widely used in multiple fields:

- Aerospace: Structural components used in aircraft and spacecraft to reduce weight and increase strength.

- Automotive industry: used for manufacturing body panels, engine components, etc. to reduce vehicle weight and improve fuel efficiency.

- Sports equipment: used for producing bicycle frames, golf clubs, tennis rackets, etc. to improve performance and durability.

- Building reinforcement: used to reinforce structures such as bridges and high-rise buildings, improving their load-bearing capacity and seismic resistance.

- Wind power industry: used to manufacture wind turbine blades to enhance rigidity and reduce weight.

- Electronic products: used for laptop cases, phone frames, etc., to provide a lightweight and sturdy appearance.

Processing and Forming

Carbon fiber filaments can be processed in various ways to meet different application needs: