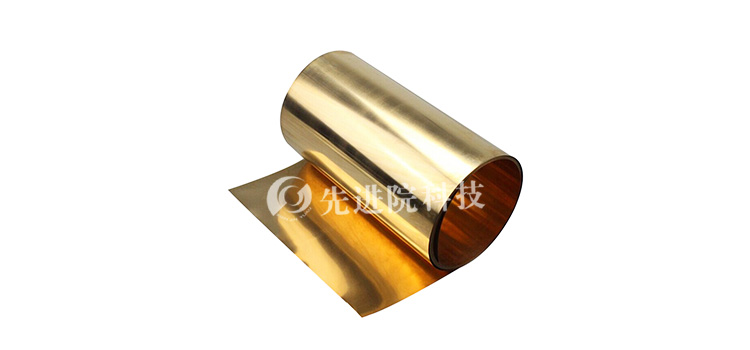

PET gold-plated reflective filmIt is a special protective film made of PET as the substrate, coated with magnetron gold on the surface, and bonded with acrylic adhesive and release film. This product has multiple characteristics and a wide range of application areas, providing reliable surface protection and die-cutting transfer solutions for various industries.

1、 Composition: Unique manufacturing process ensures quality

The production process of PET gold-plated reflective film is relatively complex, but it is precisely this unique technique that ensures its high quality. This product uses PET material as the substrate and uniformly covers the metal layer on the surface of PET through magnetron gold coating technology. At the same time, acrylic glue is attached to the back and release film is attached to make the entire film more firm and tough. This manufacturing process greatly improves the wear resistance and bonding strength of PET gold-plated reflective film.

2、 Product feature: Pursuing perfection in details

1) Suitable bonding strength and good retention performance:

PET gold-plated reflective filmWhen pasted onto objects such as metal, plastic, glass, etc., it has good bonding strength and can effectively maintain its position without easy detachment. This enables it to provide reliable surface protection during product transportation.

2) Smooth and flat surface: The surface of the protective film is treated with multiple polishing and coating processes to make it smooth and flat. This not only enhances the aesthetic appeal of PET gold-plated reflective film during application, but also improves its tactile sensation and texture.

3) Soft substrate material: The substrate material of PET gold-plated reflective film is relatively soft, which allows it to better adapt to irregular surface adhesion. PET gold-plated reflective film can provide effective protection for both flat glass and curved objects.

3、 Application areas: Diverse usage scenarios

3、 Application areas: Diverse usage scenarios

1) Surface protection during product transportation: Prolonged friction and compression during product transportation may cause scratches and damage to the product surface. PET gold-plated reflective film can effectively protect the surface of the product from external environmental damage, improving the overall image and quality of the product.

2) Die cutting protection and transfer of various metal films: Metal films usually need to be die cut before use, and PET gold-plated reflective film can be used as a protective film, attached to the surface of the metal film to prevent damage during the die cutting process. At the same time, after die-cutting is completed, PET gold-plated reflective film can also be used as a transfer film to stick the metal film onto the target object.

3) Protection of various medical devices: Medical devices have very strict requirements for hygiene and safety, and PET gold-plated reflective film can provide reliable surface protection to prevent external pollution or scratches from affecting the devices. Whether it is surgical instruments or medical equipment, PET gold-plated reflective film can provide protection and extend their lifespan.

4) Die cutting carriers, transfer and waste disposal for various types of films and tapes: In the production process of films and tapes, it is often necessary to carry out processes such as die cutting, transfer and waste disposal. PET gold-plated reflective film can serve as a carrier and protective film, providing convenience and protection for these processes.

Conclusion: Whether it is surface protection of products, processing of metal films, or protection of medical devices,

PET gold-plated reflective filmCan provide reliable solutions. Its superior characteristics and wide range of applications make it the preferred choice for various industries. As a material with great market potential, PET gold-plated reflective film will play an important role in future development.