Polyimide (PI) nickel plating filmDue to its excellent mechanical performance, electrical performance, and thermal stability, it has been widely used in fields such as electronics, aviation, and aerospace. However, ensuring the performance stability of PI nickel plating film during long-term use is a key challenge. This article will explore how to ensure the performance stability of PI nickel plating film in long-term use through material selection, process optimization, and environmental control, and specifically introduce the innovative achievements of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field.

1、 Material selection

1. High quality PI substrate

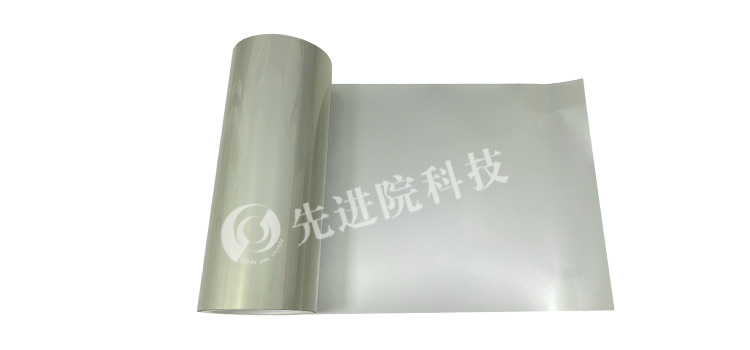

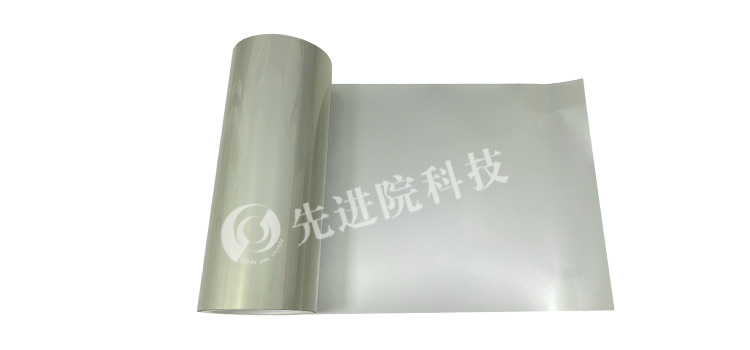

Choosing high-quality PI substrates is the foundation for ensuring the stability of PI nickel plating film performance. High quality PI substrates should have high purity, low impurity content, and uniform thickness to reduce internal defects and stress concentration points in the material. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts advanced PI substrate manufacturing technology to ensure high quality and consistency of the substrate.

2. Pure nickel layer

The purity and uniformity of the nickel layer are crucial for the stability of the performance of PI nickel plating film. A high-purity nickel layer can reduce the impact of impurities on electrical performance and corrosion resistance, and improve the conductivity and durability of the film. Advanced Institute (Shenzhen) Technology Co., Ltd. uses high-purity nickel target materials and ensures the uniformity and purity of the nickel layer through precise control of coating parameters.

2、 Process optimization

1. Magnetron sputtering coating

Magnetron sputtering coating is an advanced physical vapor deposition (PVD) technology that ensures the uniformity and adhesion of the nickel layer. By optimizing parameters such as sputtering power, sputtering time, and working pressure, the thickness and quality of the nickel layer can be controlled.

Advanced Institute (Shenzhen) Technology Co., LtdUsing high-precision magnetron sputtering equipment to ensure the stability and repeatability of the coating process.

2. Vacuum evaporation

Vacuum evaporation is a coating technology carried out in a high vacuum environment, which can reduce the mixing of impurities, improve the purity and adhesion of the nickel layer. By precisely controlling the evaporation temperature and rate, the uniformity and thickness of the nickel layer can be ensured. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts advanced vacuum evaporation equipment to ensure the stability and high quality of the coating process.

3. Surface treatment

Surface treatment is a key step in improving the adhesion between PI substrate and nickel layer. By using plasma treatment, chemical cleaning and other methods, impurities and oil stains on the surface of the substrate can be removed, the surface energy of the substrate can be improved, and the adhesion of the nickel layer can be enhanced. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts various surface treatment technologies to ensure the cleanliness and activity of the substrate surface.

3、 Environmental control

1. High temperature environment

Under high temperature conditions, the difference in thermal expansion coefficient between PI substrate and nickel layer may lead to cracking or delamination of the film layer. By optimizing the material formula and process parameters, the difference in thermal expansion coefficient can be reduced, and the thermal stability of the film layer can be improved. Advanced Institute (Shenzhen) Technology Co., Ltd. ensures the stability of the film layer in high-temperature environments by precisely controlling the coating temperature and substrate pretreatment.

2. High humidity environment

In high humidity environments, moisture may penetrate into the interior of the film layer, causing corrosion and performance degradation of the nickel layer. By adding protective coatings such as organic silicon coatings or polyurethane coatings on the surface of the nickel layer, the penetration of moisture can be effectively prevented, and the moisture resistance of the film layer can be improved. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts advanced coating technology to ensure the stability of the film layer in high humidity environments.

3. Chemical environment

In applications with complex chemical environments, nickel layers may be corroded by chemical substances, leading to a decrease in performance. By adding chemical resistant coatings such as fluorocarbon coatings or ceramic coatings on the surface of the nickel layer, chemical corrosion can be effectively prevented and the chemical resistance of the film layer can be improved. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts various protective coating technologies to ensure the stability of the film layer in chemical environments.

4、 Innovative achievements of Advanced Institute (Shenzhen) Technology Co., Ltd

Advanced Institute (Shenzhen) Technology Co., Ltd

PI nickel plating filmSignificant achievements have been made in research and production. The company adopts advanced material selection, process optimization, and environmental control technologies to ensure the performance stability of PI nickel plating film in long-term use. Specific innovative achievements include:

1. High quality PI substrate

The company adopts advanced PI substrate manufacturing technology to ensure high purity, low impurity content, and uniform thickness of the substrate, reducing internal defects and stress concentration points of the material.

2. Pure nickel layer

The company uses high-purity nickel target materials and precisely controls the coating parameters to ensure the uniformity and purity of the nickel layer, improving the conductivity and durability of the film.

3. Magnetron sputtering coating

The company uses high-precision magnetron sputtering equipment to optimize parameters such as sputtering power, sputtering time, and working pressure to ensure the uniformity and adhesion of the nickel layer, and improve the conductivity and durability of the film.

4. Vacuum evaporation

The company adopts advanced vacuum evaporation equipment to ensure the uniformity and thickness of the nickel layer, and improve the conductivity and durability of the film by precisely controlling the evaporation temperature and rate.

5. Surface treatment

The company adopts various surface treatment technologies, such as plasma treatment, chemical cleaning, etc., to ensure the cleanliness and activity of the substrate surface, enhance the adhesion of the nickel layer, and improve the conductivity and durability of the film.

6. Protective coating

The company adopts advanced coating technologies such as organic silicon coating, polyurethane coating, fluorocarbon coating, and ceramic coating to ensure the stability of the film layer in high temperature, high humidity, and chemical environments, and extend the service life of the film layer.

5、 Conclusion

Ensuring the performance stability of PI nickel plating film during long-term use is a multifaceted system engineering. Through high-quality material selection, advanced process optimization, and strict environmental control, the performance stability and service life of PI nickel plating film can be significantly improved. Advanced Institute (Shenzhen) Technology Co., Ltd. ensures the stability and reliability of PI nickel plating film in various complex environments through a series of innovative technologies, providing strong support for high-end applications in electronics, aviation, aerospace and other fields. In the future, with the continuous advancement of technology, PI nickel plating film will demonstrate its enormous application potential in more fields.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.