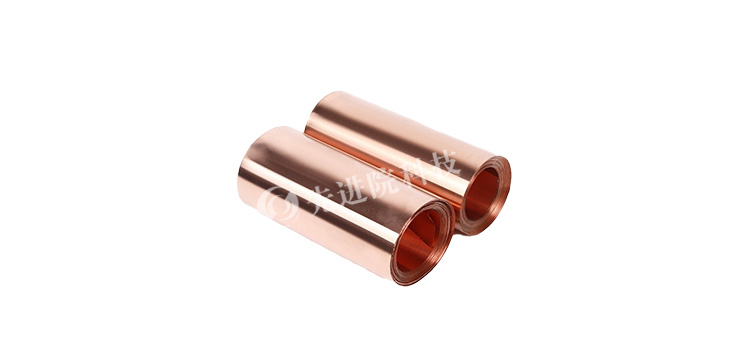

PET copper plated filmDue to its conductivity, corrosion resistance, and good plasticity, it is widely used in high-precision electronic components, printed circuit boards, solar cells, and other fields. However, during use, oxidation spots may appear on the surface of PET copper plated film, affecting product performance and aesthetics. This article will explore the possible causes and solutions from two aspects, and analyze them based on the technical experience of Advanced Institute (Shenzhen) Technology Co., Ltd.

1、 Possible reasons for surface oxidation spots on PET copper plated film

-

environmental factor

- Oxygen and water vapor in the air: PET copper plated film exposed to air for a long time will react with oxygen and water vapor to form copper oxide, resulting in surface spots.

- Temperature and humidity changes: High temperature and high humidity environments can accelerate the oxidation process, especially during sudden temperature changes, such as transferring from a high temperature environment to a cool environment, condensation water will be generated inside the packaging, further accelerating oxidation.

-

technology factor

- Residues during electroplating process: Residues that have not been thoroughly cleaned during electroplating, such as impurities in chemical nickel plating tanks and water washing tanks after bright chromium plating, may become causes of oxidation spots.

- Insufficient drying: Insufficient drying steps after electroplating can result in residual moisture on the film surface, increasing the risk of oxidation.

-

Storage and packaging

- Packaging materials: Using packaging materials containing sodium sulfide, such as corrugated cardboard pulp, prolonged sealed storage can cause the electroplated surface to be vulcanized and discolored.

- Storage environment: Long term storage in a humid, acidic or alkaline environment will acceleratePET copper plated filmThe oxidation process.

2、 Solution method

-

Optimize electroplating process

- Strengthen cleaning: Ensure that every step of the electroplating process is thoroughly cleaned to avoid residue from affecting the surface of the film.

- Improve drying efficiency: Optimize the drying process to ensure that the surface of the electroplated film is completely dry and reduce residual moisture.

-

Improve storage and packaging conditions

- Choose appropriate packaging materials: Avoid using packaging materials containing sodium sulfide and choose packaging materials that are harmless to the electroplating surface.

- Control storage environment:PET copper plated filmStore in a dry and well ventilated environment, avoiding long-term exposure to damp, acidic or alkaline environments.

-

Use antifungal agents

- Adding mold inhibitor: Adding an appropriate amount of mold inhibitor to the last water washing tank of electroplated parts can effectively prevent the growth of mold and reduce the production of oxidation spots.

- Advanced Institute (Shenzhen) Technology Co., LtdSolution: Advanced Institute (Shenzhen) Technology Co., Ltd. has developed an efficient mold inhibitor product to address the issue of surface oxidation on PET copper plated films. This product not only effectively prevents the growth of mold, but also forms excellent anti mold performance without damaging the brightness of the workpiece itself.

-

Regular inspection and maintenance

- Regular inspection: Regularly inspect the PET copper plated film to promptly detect and treat oxidation spots.

- Maintenance measures: For film surfaces that have already undergone slight oxidation, they can be gently wiped with fine sandpaper or a fine wire brush to remove the oxide layer. For heavily oxidized membrane surfaces, more complex treatments such as soaking in acid solutions are required.

3、 Conclusion

The appearance of oxidation spots on the surface of PET copper plated film is a complex problem that requires comprehensive consideration from multiple aspects such as environmental factors, process factors, storage, and packaging. By optimizing the electroplating process, improving storage and packaging conditions, using mold inhibitors, and conducting regular inspections and maintenance, the generation of oxidation spots can be effectively reduced, the service life of PET copper plated films can be extended, and their performance and aesthetics can be improved. As a leading enterprise in the industry, Advanced Institute (Shenzhen) Technology Co., Ltd. will continue to be committed to researching and developing more efficient and environmentally friendly solutions, contributing to the application and development of PET copper plated films.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.