Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

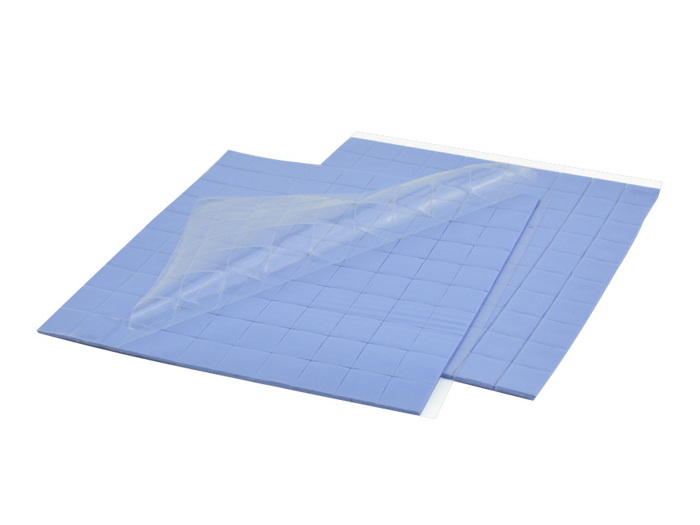

Generally, conductive fibers, resins, and loss media are mixed uniformly and directly hot pressed or sprayed into shape. In single-layer coating structures, the fiber content and arrangement direction have an impact on the dielectric properties of composite laminates: the larger the angle between the fiber and the direction of the applied electric field, the higher the electrical breakdown strength of the laminate; As the fiber content increases, the dielectric properties of the unidirectional fiber composite laminate decrease. Developed using ferrite (sintered body), phenolic resin, and steel wireSingle layer absorbing coatingAbsorbing materials made by mixing ferrite powder, polyethylene resin powder, and short steel wire, dispersing them in organic solvent xylene, and applying pressure. However, single-layer coatings have a narrow absorption frequency band and cannot meet the requirements of stealth for lightweight and wideband coatings. The development of double-layer and multi-layer coating structures is necessary to meet these requirements.

The earliest to appearAbsorbing material RAMIt's a single layer. Absorbing materials are not only used in breakthrough technology, but developed countries are also required to coat high-rise buildings, bridges, iron towers, ships, etc. with absorbing materials to eliminate clutter interference. If ferrite (sintered body) 10%~80%, phenolic resin 5%~80%, steel wire diameter 10-100m, length 1-5mm are used to form a single-layer absorbing coating, the characteristic of this absorbing material is to provide the requirements for the steel wire.

Using 56% (mass fraction) of ferrite powder, 24% (mass fraction) of polyethylene resin powder, and 20% (mass fraction) of short steel wire, after mixing and dispersing in organic solvent xylene, a 200mm wide and 3mm thick blank plate is made. It is heated on a 250 ℃ drum at a pressure of 1.96MPa to produce a 200mm/200mm × 2.8mm absorbing material. Advanced Institute Technology conducted research on the influence of fiber content and arrangement direction in composite materials on the dielectric properties of unidirectional glass fiber/epoxy composite laminates. The results indicate that changing the direction of the fiber and the applied electric field will cause a significant change in the electrical breakdown strength of the composite laminate, with the greater the angle between the fibers and the laminate, the higher the electrical breakdown strength it can withstand; As the fiber content increases, the dielectric properties of the unidirectional fiber composite laminate decrease.

Radio wave absorberEqually important as insulation materials and stealth materials in emerging buildings. According to some patent reports, ferrite powder, synthetic resin, and fibers are mixed in a certain proportion to form a paste, which is coated on a spring metal mesh placed on the substrate material. Its absorption reflection attenuation is 14dB and the bandwidth is 813GH1z. After mixing ferrite powder with carbon black and bonding it with synthetic resin, there is a specialized molding machine that can be mass-produced. The absorption performance deteriorates above 8GHz, and the general reflection coefficient is 0.1.

Using the method of chloroprene rubber "concrete", it can absorb radar waves at 7.5GHz. This "concrete" includes 150 parts chloroprene rubber, 3 parts phenyl naphthylamine, 7.5 parts zinc oxide, 6 parts calcined magnesium oxide, 0.75 parts stearic acid, 84 parts semi reinforced carbon black, and 494 parts xylene. First, mix phenyl B naphthylamine, magnesium oxide, zinc oxide, and carbon black in a closed mixer (Banbury mixer) at 43 ℃ for 3 minutes, then cool down to 35 ℃ and add chloroprene rubber. Afterwards, raise the temperature to 88 ℃ within 7 minutes and mix at 88-93 ℃. Put the obtained mixture into a roller and add zinc oxide at room temperature. Place the mixture in a paddle mixer and add 1/2 xylene for continuous stirring for more than 5.5 hours. Filter the obtained "concrete" containing 33.7% (mass fraction) solids to remove insoluble clots.

Mix 171 parts (by mass) of "concrete" containing 33.7% solids with 12.6 parts of graphite and 42 parts of toluene (dry the mixture in a closed container for 16 hours), then apply the mixture onto a glass or rubber plate (pre covered with 0.025mm polyethylene film) and dry at room temperature for 30 minutes. Apply another 9 layers using the same method, then remove the glass or rubber plate. Finally, let the solvent evaporate at 70 ℃ for 24 hours, and vacuum insulate at 140 ℃ for 1 hour. By pressing three layers of this 0.5mm thick film containing 119% (volume fraction) graphite and 22.7% (volume fraction) carbon black, a film with good absorption of microwaves at 7.5GHz was obtained.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2