1、 Introduction

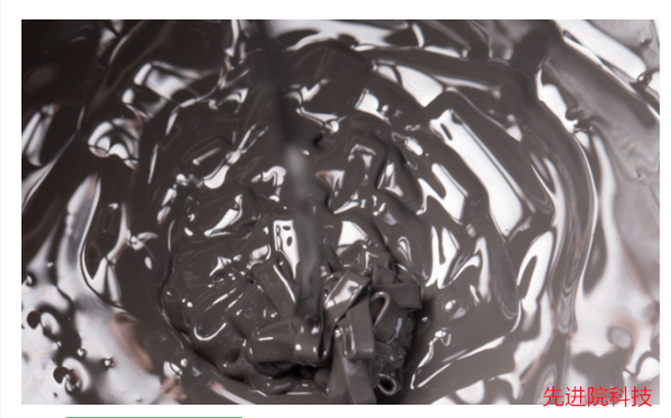

Heating thick film resistor pasteIt is a material commonly used in electrical equipment, suitable for various substrate materials such as ceramic substrates, stainless steel tube substrates, etc. It can be used to produce heating films through screen printing or coating processes, with advantages such as strong adhesion, low power attenuation, and stable and reliable heating. In addition, this series of slurries also meets environmental requirements, does not contain harmful substances, and is suitable for heating electronic cigarette cores, household appliances, heaters, and other electrical equipment.

2、 Process flow

The production process of heating thick film resistor paste includes two main steps: screen printing and sintering.

1. Screen printing

Screen printing is a common process for making heating films. Using a mesh size of 200-325 mesh for screen printing can obtain a uniform and appropriately thick film layer. Screen printing can simplify operations and improve production efficiency during the manufacturing process.

After making the heating film, two steps of drying and sintering are required to achieve the desired performance of the heating film.

(1) Drying

Place the screen printed substrate into a hot air drying oven for drying treatment. The drying conditions are 150-200 ℃, and the time is usually 3-5 minutes. By drying, solvents in the slurry can be removed and the film layer can be cured.

(2) Sintering

After drying, the substrate needs to be sintered to better bond the slurry with the substrate and improve the stability of the heating film. The sintering conditions can be set according to the specific requirements of the slurry, usually at a temperature of 700 ℃ -1200 ℃ and for 5-10 minutes.

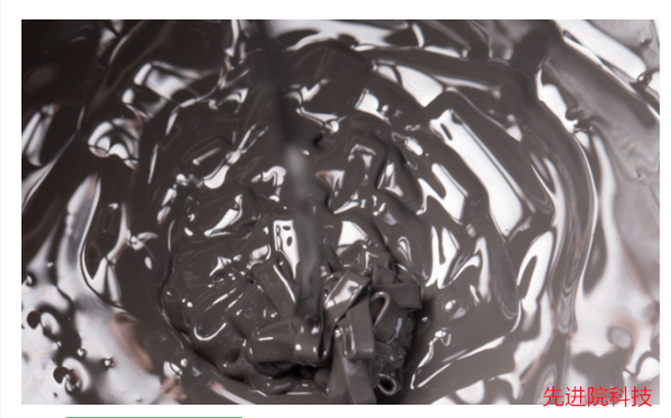

Taking the heating of electronic cigarette cores as an example, this article introduces the application of heating thick film resistor paste.

The electronic cigarette core is the core component of electronic cigarettes, in which the heating film plays a role in heating the e-liquid to produce smoke. The heating film made of heated thick film resistor paste has excellent heating performance, which can stably and uniformly heat e-liquid, providing a pleasant smoking experience.

Experimental results have shown that electronic cigarette cores made using heated thick film resistor paste have the following advantages:

1. Stable heating performance: The heating film is made of slurry, which can achieve uniform and stable heating effect, avoiding changes in taste and smoke quality caused by uneven heat.

2. High adhesion: The heated thick film resistor paste has strong adhesion, which can ensure that the heating film is firmly fixed on the substrate and is not easily peeled off or damaged after long-term use.

3. Low power attenuation: The heating film is made of slurry and has low power attenuation, which can maintain stable heating power and extend the service life of electronic cigarettes.

in summary,

Heating thick film resistor pasteIt is an ideal heating material with stable and uniform heating effect, suitable for various electrical equipment. Taking electronic cigarette heating as an example, we can see its advantages in providing a pleasant smoking experience. Therefore, heating thick film resistor paste has broad application prospects in the field of electrical equipment manufacturing.