Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

PP double-sided copper platingIt is a new type of composite material composed of PP substrate and double-sided copper coating. PP double-sided copper plating has excellent electrical insulation, high temperature resistance, corrosion resistance, and arc resistance, and is therefore widely used in the packaging of electronic devices, chip packaging, and sensor manufacturing. The production process of PP double-sided copper plating is to first treat the surface of the PP substrate, then cover it with a layer of copper on both sides, and finally undergo heat treatment to form the final PP double-sided copper plating. PP double-sided copper plating has excellent thermal stability, which can effectively resist the effects of high and low temperatures, suppress the deformation and damage of electronic components, and thus improve the reliability of electronic components.

PP double-sided copper plating also has good corrosion resistance, which can effectively prevent corrosion of metal surfaces and significantly improve the service life of electronic components. In addition, PP double-sided copper plating also has good conductivity, which can effectively reduce the resistance of electronic components, improve the working efficiency of electronic components, and thus enhance the efficiency of electronic components. In addition, PP double-sided copper plating also has good moisture resistance, which can effectively resist the erosion of humid environments, thereby improving the service life of electronic components.

In short,PP double-sided copper platingIt is a very practical technology that can effectively block external electromagnetic waves and resist interference, thereby protecting internal electronic components from external interference. It can also improve the conductivity and moisture resistance of electronic components. Therefore, its application can significantly improve the reliability and stability of electronic components, making it a very practical technology. Therefore, PP double-sided copper plating technology is expected to have greater development and application in the future.

Copper plating is a new surface treatment technique aimed at obtaining a conductive copper coating on a metal substrate, commonly referred to as copper plating.

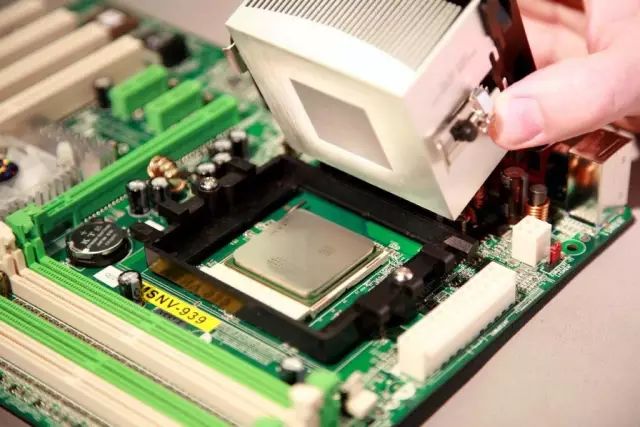

When copper plating on plastic surfaces, it is necessary to first remove the oxide film and other dirt on the plastic surface, and then immerse it in a chemical solution or treat it with other methods.

Copper plating is the process of depositing a layer of non-ferrous metal on a metal or alloy substrate to enhance its physical and chemical properties.

Due to the easy transfer of copper ions from the substrate to the coating, the copper content in the plated part is generally low (about 5%).

Due to the need to obtain a copper coating with a certain thickness on the copper surface, pre-treatment must be carried out first to remove oxides, dust, and other substances on the substrate surface.

At present, there are two main processes for plastic copper plating: electroplating and chemical plating

Electroplating is a process of functionalizing metal surfaces by utilizing the dissolution effect of ions on the metal substrate. It is mainly used for thin copper layer electroplating to improve the bonding strength between the coating and the substrate.

Electroplating is divided into two types: hot-dip plating and chemical plating. Among them, hot-dip plating is further divided into salt bath method, chelating agent method, surface activation method, and chemical plating.

Copper plating based on zinc is commonly used in electroplating production, which is a widely used coating in industrial production. The main preparation methods include electroplating, hot-dip galvanizing, hot-dip galvanizing, and electroless nickel plating.

The most commonly used technology currently is electroless nickel plating, which is also the most widely used metal surface treatment method in industrial production.

Due to the high bonding strength and good corrosion resistance between the electroplated nickel metal layer and the base metal, it is widely used in various metal products.

Nickel electroplating is a commonly used surface treatment process in modern industrial production, which can endow various metal products with special surface properties such as beauty, high temperature resistance, and wear resistance. It can effectively improve product quality, save materials, and reduce energy consumption and environmental pollution, and has broad development prospects and application space.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2