Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

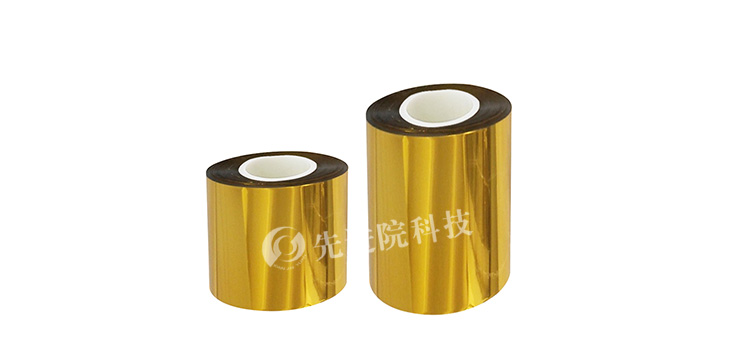

With the rapid development of industries such as electronics and decoration,PP gold-plated filmThe application is becoming increasingly widespread. However, deformation of PP substrate has always been a difficult problem for production enterprises during the gold plating process. Advanced Institute (Shenzhen) Technology Co., Ltd. has conducted in-depth exploration on this issue through long-term research and practice, accumulated rich experience, and formed a series of effective solutions.

There is a significant difference in the thermal expansion coefficient between PP substrate and gold plating layer. In the process of gold plating, especially when it involves heating, such as high temperature of plating solution or subsequent drying treatment, due to the uneven thermal expansion of the two materials, stress will be generated inside the substrate. When the stress exceeds the bearing limit of the substrate, it will cause deformation.

The chemical treatment and physical effects during the gold plating process may have an impact on the internal structure of the PP substrate. For example, certain chemical reagents may penetrate into the interior of the substrate, causing rearrangement or partial degradation of molecular chains, thereby altering the mechanical properties of the substrate and making it more prone to deformation.

Improper setting of process parameters such as current density, plating time, and plating solution composition during electroplating may result in uneven thickness of the gold plating layer. Uneven gold plating can cause uneven stress on the surface of the substrate, leading to deformation. For example, in areas with excessive current density, the growth rate of the gold plating layer is fast and the thickness is large, which will cause significant pulling force on the substrate.

existAdvanced Institute (Shenzhen) Technology Co., LtdOn the experimental production line, the PP substrate gold plating process was improved according to the above solution. After production verification of multiple batches of products, the results show that the deformation rate of PP substrate during the gold plating process has been reduced from the original 20% -30% to below 5%, the uniformity of the gold plating layer has been significantly improved, the quality and qualification rate of the product have been greatly improved, and the production efficiency has also been guaranteed to a certain extent.

The deformation of PP substrate during gold plating process is a complex problem involving multiple factors. The complete solution proposed by Advanced Institute (Shenzhen) Technology Co., Ltd., which includes substrate pretreatment, gold plating process parameter optimization, and post-treatment, can effectively reduce the occurrence rate of substrate deformation and improve product quality. In the actual production process, enterprises can further adjust and optimize these plans according to their own equipment conditions, product requirements, etc., to achieve the best production effect and meet the market's demand for high-quality PP gold-plated film products.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2