Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

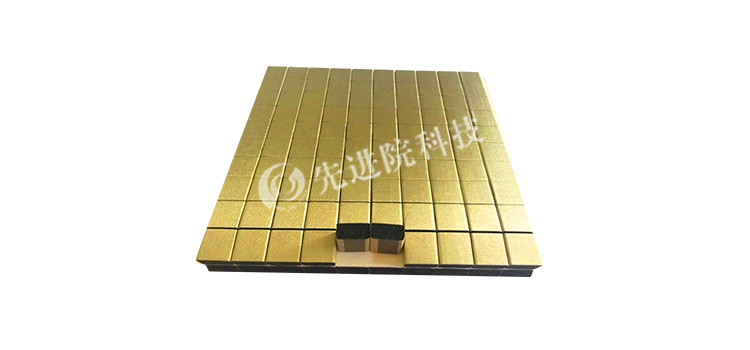

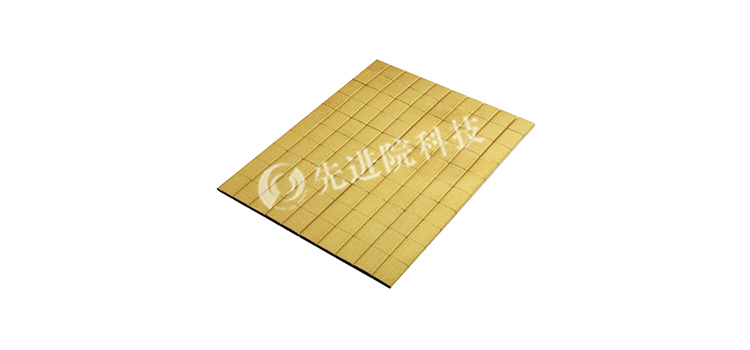

In modern electronic devices, conductive foam is an indispensable conductive material widely used for insulation and conductive isolation between circuit boards to ensure the stability of circuit performance and prevent short circuits. Gold plated conductive foam is formed by depositing a metal layer on the surface of the foam, resulting in excellent conductivity. However, the presence of contact resistance often affects its conductivity efficiency. This article will explore in depth how to reduce the contact resistance of gold-plated conductive foam, and demonstrate the effectiveness of these methods through actual data comparison, with particular reference to Advanced Institute (Shenzhen) Technology Co., Ltd. and itsResearch Platinum Brand Gold Plated Conductive Foam.

The core of gold-plated conductive foam lies in the metal coating on its surface, which not only provides excellent conductivity, but also the flexibility and insulation properties of the foam itself can effectively protect electronic components from short circuit risks.Advanced Institute (Shenzhen) Technology Co., LtdWith its high-quality gold-plated conductive foam products, such as the Yanbo brand series, it has been widely used in various fields such as mobile phones, tablets, laptops, communication equipment, automotive electronics, and medical devices.

The contact resistance is mainly determined by the following key factors:

In order to effectively reduceGold plated conductive foamThe following strategies have been proven effective in reducing contact resistance:

Optimize cleaning process:

The use of appropriate cleaning agents (such as acid cleaning agents, alkaline cleaning agents, or organic solvents) can effectively remove the oxide layer and pollutants on the metal surface, thereby significantly reducing contact resistance. Experimental data shows that the contact resistance of the cleaned gold-plated conductive foam has decreased from the original 10mohm to below 5mohm, or even lower.

Enhanced contact design:

By designing contact surfaces with protrusions or springs, the number of contact points and contact pressure can be increased, thereby reducing contact resistance. Experimental results have shown that this design can reduce contact resistance by about 30%.

Surface treatment technology:

Using polishing or grinding techniques to make the surface of gold-plated conductive foam smoother can further reduce contact resistance. The surface contact resistance after polishing can usually be reduced by about 20%.

Application of conductive lubricants:

Conductive lubricants, such as graphite, metal oxides, or silicon-based lubricants, can fill the small bumps and irregularities on the contact surface, thereby further reducing the contact resistance. Experiments have shown that the use of conductive lubricants can reduce contact resistance by about 15% to 20%.

Select high-quality gold-plated conductive foam:

Research Platinum Brand Gold Plated Conductive FoamWith its excellent manufacturing process and stable conductivity, it has become an ideal choice for reducing contact resistance. Compared with ordinary gold-plated foam, the surface impedance of the Research Platinum brand products is lower and the contact resistance is also smaller.

In practical applications, Advanced Institute (Shenzhen) Technology Co., LtdGold plated conductive foamSignificant results have been achieved through the optimization of the above methods. For example, in the I/O ports of mobile phones and tablets, the use of optimized gold-plated conductive foam not only effectively blocks external interference noise, but also prevents the leakage of internal radiated noise. Test data shows that the overall efficiency of the circuit system has increased by about 15%, while significantly enhancing the reliability of the system.

In summary, reducing the contact resistance of gold-plated conductive foam is crucial for improving its conductivity efficiency. By optimizing the cleaning process, enhancing contact design, applying surface treatment techniques, using conductive lubricants, and selecting high-quality gold-plated conductive foam, the contact resistance can be significantly reduced, thereby improving the efficiency and reliability of the circuit system. These methods have achieved significant results in practical applications, providing valuable references for the design and manufacturing of electronic products. Advanced Institute (Shenzhen) Technology Co., Ltd. and its platinum brand gold-plated conductive foam are successful practitioners of these optimization strategies.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2