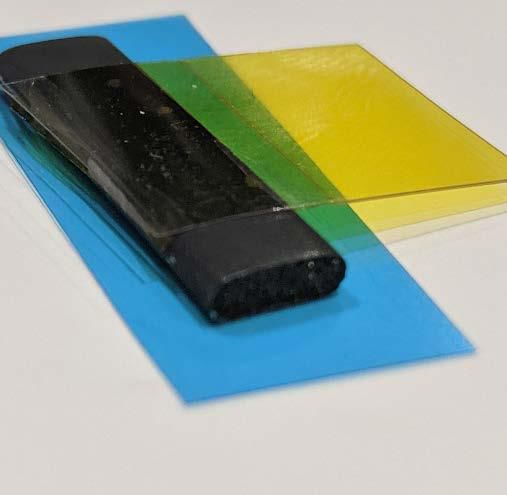

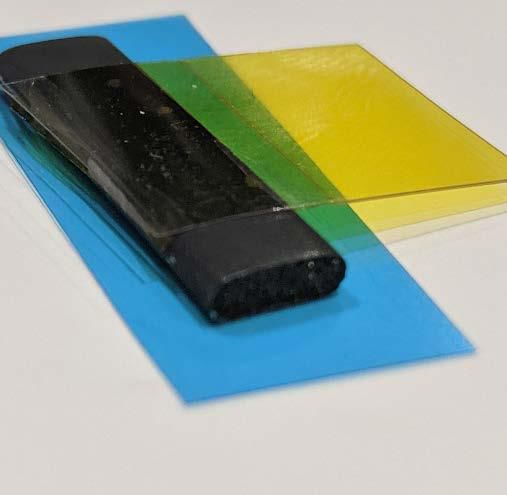

Two tone molded productsIt refers to a product that is processed using two different colors and material types simultaneously. The surface of this product usually has multiple colored decorations or shells made of different material types to adapt to different application scenarios.

The following are common types of two-color molded products:

Window components: Window components used on the exterior of cars, buses, and other vehicles, usually manufactured using dual color molding technology, where one color is the window body and the other is the coating or decoration. These components typically have large areas of glass and decorative strips to provide a beautiful view.

Aviation components: In the aviation field, two-color molded products can be used to manufacture aircraft wings, fuselage and other components. In short, two-color molded products are widely used industrial products in various fields, which can provide various needs such as beauty, practicality, and aesthetics. When selecting, it is necessary to choose based on specific application scenarios and requirements to ensure that product quality and performance meet the requirements.

1、 Characteristics of two-color molded products:

1. Has the characteristics of good water resistance and strong UV resistance;

2. It has the advantages of light weight, high strength, good toughness, not easy to deform, not easy to crack, and long service life;

3. Smooth surface, bright color, and beautiful appearance;

4. Easy to process, strong plasticity;

5. Low price;

6. Convenient construction;

7. Widely applicable and suitable for various occasions.

2、 The use of two-color molded products:

1. Used for building interior and exterior walls, indoor and outdoor decoration, floors, rooftops, partitions, etc., such as exterior wall panels, interior wall panels, ceilings, floors, baseboards, corner guards, door frames, window sills, waistlines, threshold stones, fireplaces, flues, pipe shafts, elevator shafts, bathrooms, balconies, kitchens, bathrooms, pools, gardens, swimming pools, flower stands, etc.

2. Used for lining, cushioning, outer shell, box, cover, pallet, bottom plate, shelf, counter, display cabinet, exhibits, display racks, advertising signs, telephone booths, waiting rooms, cold storage, warehouses, docks, gas stations, airports, stations, hotels, restaurants, hotels, shopping malls, banks, hospitals, schools, factories, offices, military units and other transportation vehicles such as furniture, appliances, kitchenware, sanitary ware, toys, handicrafts, cars, ships, planes, trains, motorcycles, etc.

3. Used for the protection, insulation, sound insulation, sealing, heat insulation, moisture prevention, dust prevention, insulation, rust prevention, fire prevention, waterproofing, theft prevention, oil prevention, corrosion prevention, wear resistance, acid and alkali resistance, impact resistance, anti-static, high temperature resistance, oxidation resistance, odorless, non-toxic and harmless, green and environmentally friendly, energy-saving and material saving, safe and hygienic, environmental protection, energy conservation, and improved production efficiency, etc.

4. Used for protection, insulation, sound insulation, sealing, heat insulation, moisture resistance, dust prevention, insulation, rust prevention, waterproofing, anti-theft, oil resistance, anti-corrosion, wear resistance, acid and alkali resistance, impact resistance, high temperature resistance, oxidation resistance, no odor, non-toxic and harmless, green and environmentally friendly, energy-saving, improving production efficiency, extending service life, etc. in various industries, agricultural equipment and facilities, food machinery, packaging machinery.

3、 The application of two-color molded products usually includes the following steps:

Selecting raw materials: First, you need to choose two different raw materials, including color and material type.

Mixing raw materials: Put the selected raw materials into the machine and stir thoroughly.

Molding: Place the mixture into a mold for molding processing to form the desired shape.

Heat treatment: Heat treatment is carried out after forming to improve the stability and heat resistance of the material.

Inspection: Inspect the formed product to ensure that its quality meets the requirements.

Assembly and molding: Assemble and mold the molded product to complete the final product.

Dual color molded products are widely used in various fields, including automotive, electronics, communication, aviation, and more. For example, in the automotive industry, two-color molded products can be used to manufacture components such as doors, windows, front and rear lights. In the field of electronics, two-color molded products can be used to manufacture components such as display panels and electronic components. In the field of communication, two-color molded products can be used to manufacture casings for electronic devices such as smartphones and tablets. In the aviation industry, two-color molded products can be used to manufacture components such as wings and fuselage of aircraft.

It should be noted that different application scenarios may have different requirements for two-color molded products. Therefore, when choosing, it is important to carefully read the relevant documents or instructions to ensure that the quality and performance of the product meet the requirements.