Why do we have to choose

Anti static PETTo understand the issue of using conductive PET instead of low-cost ordinary insulating PET, we need to start with static electricity itself!

Simply put, static electricity is a type of electric atom that generates micro charges through friction between objects. It exists in space at all times. In spring and summer, due to abundant rainfall and high humidity, the charges generated on the surface of objects are carried by water vapor along the skin or surface of objects to the ground and disappear. However, in autumn and winter, due to the relatively dry surface and skin of objects, the charges generated will generate electric sparks - static electricity - once they encounter charges of opposite electrical properties. Due to the high surface resistance value of ordinary PET, generally above 1011, it is only suitable for use as an insulator!

Now that we understand the principle of static electricity generation, we can clearly understand why we use anti-static PET and conductive PET in electrical products (especially electronic components)!

That's right, the purpose of using anti-static PET is to utilize anti-static PET

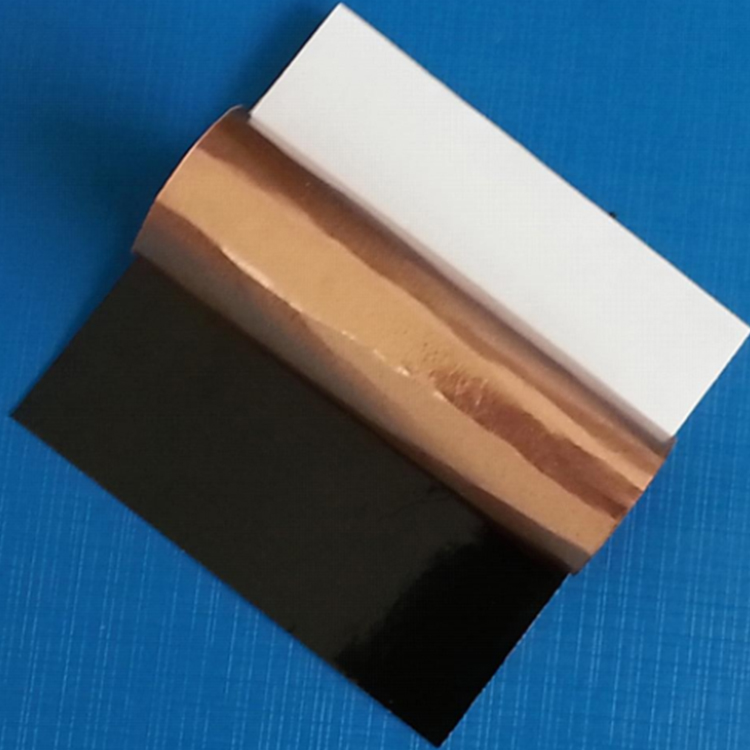

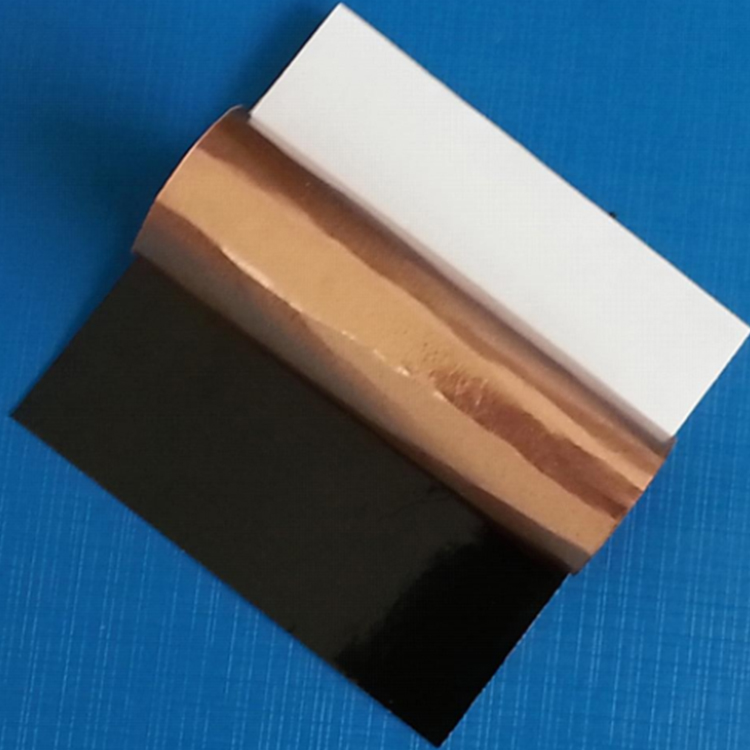

Conductive PETEffectively eliminating electric sparks generated by electrostatic charges in electronic components due to their inherent characteristics, thereby minimizing potential risks! When electronic components are in operation, electric ions are generated due to the operation of surface currents, causing static sparks of different sizes of charges. When the static sparks are small, their impact on electronic components is relatively small. However, when the electrical sparks accumulate to a certain extent, they will generate a strong instantaneous current and cause the danger of circuit fire or even explosion!

Knowing the efficacy of anti-static PET and conductive PET, we will now focus on explaining the composition of anti-static PET and conductive PET products based on their characteristics, as well as how to achieve the function of eliminating static electricity:

1. Anti static products refer to products with surface resistance values between 106-109 and surface voltage below 100V. (Less than 106 is a conductor, and more than 1011 is an insulator).

2. The working principle of anti-static PET is to maintain the surface resistance value of PET between 106-109 through special treatment, thereby creating a uniform and thin layer of water layer on its surface. When static electricity is generated inside electronic components, it can be quickly conducted to the outside through the water layer on the surface of anti-static PET, minimizing the danger!