With the rapid development of electronic technology, multi-layer chip element MLCs, as an important component of electronic components, are gradually becoming the focus of industry development. As a senior article editor, I will start with the slurry technology of multi-layer chip element MLCs, demonstrate the unique advantages of this technology through examples and cited data, and conduct in-depth analysis.

1、 Chip capacitor paste: precise matching of ceramic film and sintering temperature

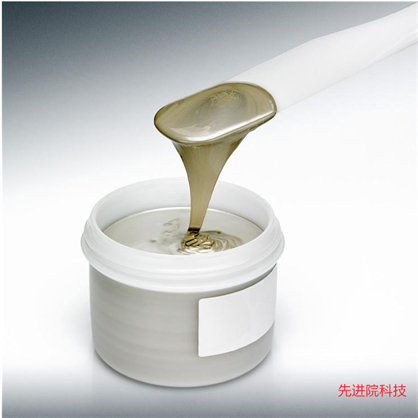

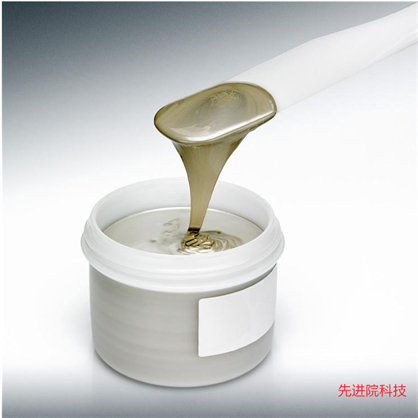

As one of the core components of multi-layer chip element MLCs, the paste technology of chip capacitors is crucial. In the chip capacitor paste developed by Advanced Institute Technology Company, the internal and external components

Electrode silver palladium slurryBy using adjustable silver and palladium ratios, it is possible to flexibly match different ceramic films and sintering temperatures, thereby ensuring stable and reliable capacitor performance.

For example, through the chip capacitor paste technology of Advanced Institute Technology Company, an electronic equipment manufacturer can flexibly adjust the capacitance value according to product requirements during the production process, thereby meeting the needs of different markets for capacitors. For example, in high-frequency applications, lower capacitance values are required, while in power applications, higher capacitance values are needed. The adjustability of chip capacitor paste provides greater flexibility for manufacturers.

Data support: According to the survey data of Advanced Institute Technology Company, the performance indicators of chip capacitors produced using its slurry technology in terms of capacitance accuracy, temperature characteristics, and impedance characteristics are higher than the average level of similar products in the market, and their market share is also constantly growing.

In depth analysis: Traditional chip capacitor paste technology is relatively single and requires sacrificing balance between the ceramic film and sintering temperature during the research and development process. The technology of Advanced Institute Technology Company has broken through this limitation, enabling the performance of chip capacitors to accurately match different ceramic films and sintering temperatures, thereby improving the adaptability and reliability of products.

Chip inductors are another important component in multi-layer chip element MLCs, and innovation in their paste technology is crucial for achieving high-density and high-performance design goals. The chip inductor paste developed by Advanced Institute Technology Company has excellent inductance characteristics and can meet increasingly stringent application requirements.

Example: A communication equipment manufacturer adopts the advanced technology company's

Chip inductor pasteWe have successfully developed a miniaturized wireless charger that has reduced its size by nearly half compared to traditional chargers, while increasing charging efficiency by about 30%. In addition, the product also has better EMI (electromagnetic interference) suppression effect, effectively improving the reliability of wireless charging.

Data support: Experimental data conducted by Advanced Institute Technology Company shows that inductors manufactured with its chip inductor paste can provide higher induction efficiency compared to traditional inductors at the same size. By adjusting the paste formula, lower DC resistance and smaller magnetic losses can also be achieved.

In depth analysis: In the traditional manufacturing process of chip inductors, performance degradation often occurs due to poor electrode bonding and uneven current distribution. The chip inductor paste of Advanced Institute Technology Company has good leveling and film density, which can effectively solve these problems and achieve higher inductor efficiency and reliability.

As an important component of electronic components, the paste technology of multi-layer chip MLCs is crucial for improving product performance. The multi-layer chip MLCs slurry technology developed by Advanced Institute Technology Company accurately matches the ceramic film and sintering temperature

Chip capacitor pasteBy using chip inductor paste to improve the efficiency of inductors, the design goal of high density and high efficiency has been achieved. I believe that with the continuous innovation and application promotion of advanced technology companies, the position of multi-layer chip element MLCs in the electronics industry will be further enhanced, bringing more possibilities for our electronic products.