Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

ITO is indium tin oxide, a common transparent conductive material in the display industry. It can be used on PET optical films to make ITO transparent conductive films, or on glass to make ITO sensing glass or display liquid crystal glass.

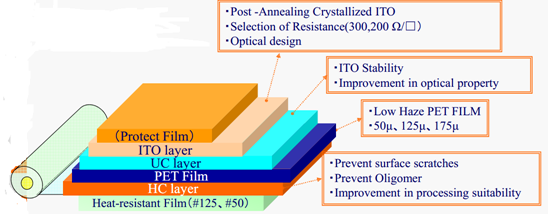

ITO film structure

The main topic here is ITO transparent conductive film, which is one of the core materials in the touch screen industry. The common structures are as follows:

From top to bottom, the topmost layer is a protective ITO layer. ITO manufacturers prevent scratches on the ITO coating during packaging and shipping, and ITO processing manufacturers must remove this protective film before use. The protective film is mostly a relatively inexpensive PE protective film.

The ITO layer is the main functional layer, and there are many production processes for coatings. However, the optoelectronic industry often uses magnetron sputtering technology, and the coating is generally multi-layer, with each layer being several thousand angstroms. The thickness of ITO layers on the market ranges from 20 to 50 nanometers. During the sputtering process, the metal In and Sn atoms bombarded from the target material react with oxygen atoms in the vacuum chamber or on the substrate surface to generate metal oxides such as In2O3, InO, SnO2, SnO, and Sn3O4. These reaction products are closely related to the sputtering process parameters and have an impact on the photoelectric properties of ITO thin films.

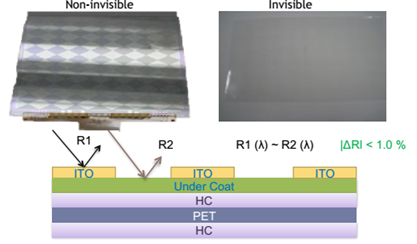

The UC layer is an optical performance adjustment layer, also known as an attenuation layer or IM layer, a refractive index matching layer, and can also be used as a coating for anti Newton rings. Due to the different refractive indices of ITO and PET layers, the greater the difference in refractive index when light passes through materials with different refractive indices, the higher the reflectivity. This can cause obvious traces of the circuit after ITO etching, affecting the appearance of the screen. Therefore, a refractive index matching layer needs to be coated. It is necessary to ensure that the reflectivity of the light on the ITO surface is close to that on the erasing surface, less than 1%, as shown in the figure below, in order to avoid the defect on the left side of the figure. The precision coating requirements for this coating are relatively high, and many Japanese companies are able to do it well now. Many ITO film factories simply purchase IM films.

Below is the optical grade substrate PET, with a common thickness of 188125,50um. We need good light transmittance, low haze, stable size, small longitudinal and latitudinal differences in MDTD, and minimal precipitation of small molecules.

The other side of the PET substrate is the Hard Coating, which prevents scratches during ITO processing. Generally, it is a coating of silicon dioxide that can prevent the precipitation of PET small molecules. The pencil hardness is around 2H.

The bottom layer is a high-temperature resistant PET protective film, which is an optional layer. Generally, customers who produce touch screens using roll to roll technology need this layer. The protective film on the back needs to be resistant to ITO shrinkage and annealing processes, with a temperature of about 150 degrees for 2 hours. While maintaining dimensional stability, it needs to be close to the PET of the ITO substrate in terms of expansion and contraction, otherwise it is very easy to cause material curling, which can lead to defects.

ITO characteristics

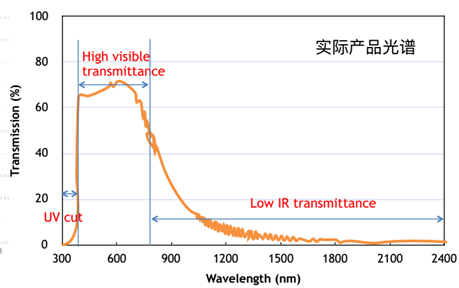

The main components of ITO are indium oxide and tin oxide, which are substances with high visible light transmittance.

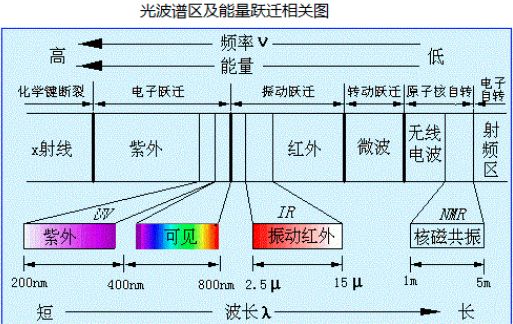

ITO has different transmittance at the wavelength frequencies of ultraviolet, visible light, and infrared, mainly transmitting visible light, while the transmittance of UV ultraviolet and IR infrared is not high. This characteristic is related to the micro electronic energy level transitions and other electrical properties of ITO materials, rather than what material is coated.

In addition, the transmittance of ITO is related to the crystallinity of the material. In the past, non crystalline ITO was used for sale, but now manufacturers can basically prepare the annealing process. After crystallization, the transmittance of ITO will increase, the resistance will be stable, and the resistance tolerance range will be greatly reduced.

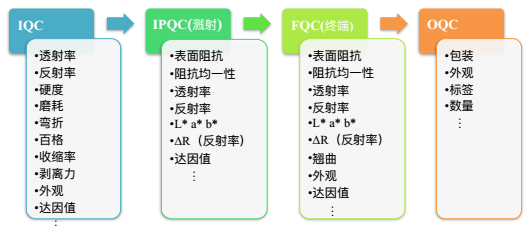

In the production of ITO, the following performance controls are generally carried out. IQC's incoming inspection IM film, controlled items in the process, and recommended items for shipment:

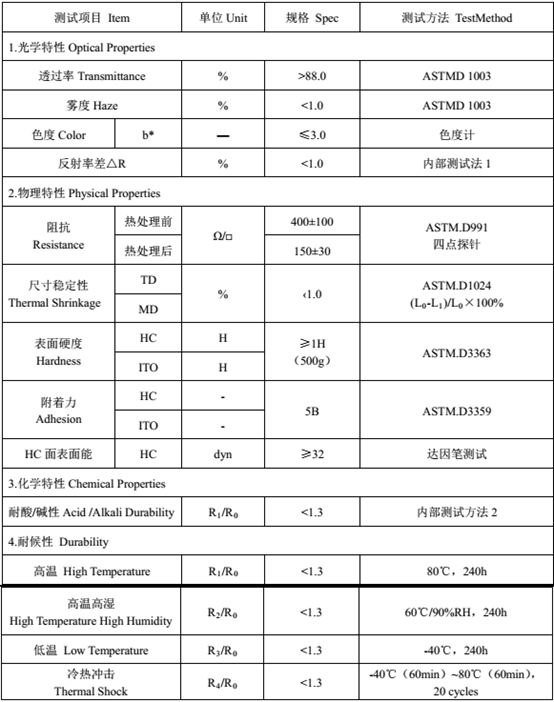

When shipping, the following specifications are generally used:

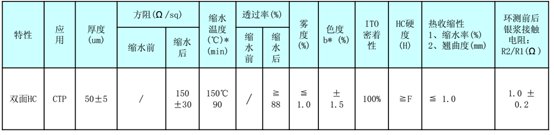

In TP factories, the following typical parameters are usually verified:

Alternative to ITO

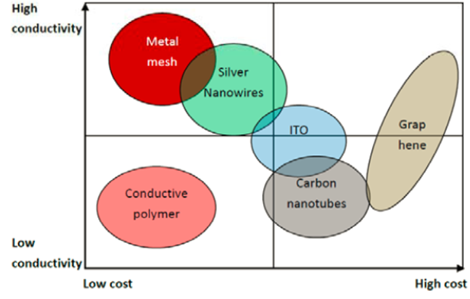

ITO film is a mature industry, and due to the large size of the TP industry in the past, there are many transparent conductive materials that want to replace it, including metal grids, nano silver, conductive polymers, carbon nanotubes, graphene, etc. However, each solution currently has its own problems.

The market for ITO

Due to the significant reduction in production of GF and GFF's thin-film capacitive touch screens, numerous factories near Shenzhen and Dongguan have closed, including those operated at a loss such as OFILM. As a result, the overall industry has been in a slump, leading to difficulties in the ITO film industry. In addition, new alternative solutions are being sought after. Due to the mass production of ITO's surface resistance, it can reach a minimum of 60 ohms, which can barely make it larger in size. However, due to its high resistance, its touch sensitivity and other properties are not as good as other low resistance transparent materials, so it is rarely used in large sizes. In addition, ITO itself is relatively brittle and not resistant to bending, so it is basically excluded from the emerging foldable market. Therefore, these two factors also prevent the market of ITO from further expanding. ITO may be able to expand into color changing films for buildings and heating films for cars, but the market has not shown great improvement. Overall, market demand is unlikely to increase.

Therefore, there are very few manufacturers producing ITO films now, and it seems that only Jiangsu Rijiu dominates, integrating upstream IM films and fully lowering prices. And what a prosperous industry it used to be, such as Nitto and Sumitomo, TDK, Lingyin, Weichi, SONY, Han Hua, Ying Hui, Kang Dexin, Ou Fei, Song Yang

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2