Lithium ion batteries are a type of modern battery with advantages such as high energy density and long cycle life, and are widely used in fields such as mobile electronics and new energy vehicles. As a key material in lithium-ion batteries, microporous aluminum foil plays an important role. This article will provide a detailed introduction to the definition, preparation methods, characteristics, and applications of microporous aluminum foil in lithium-ion batteries.

1、 Definition of microporous aluminum foil

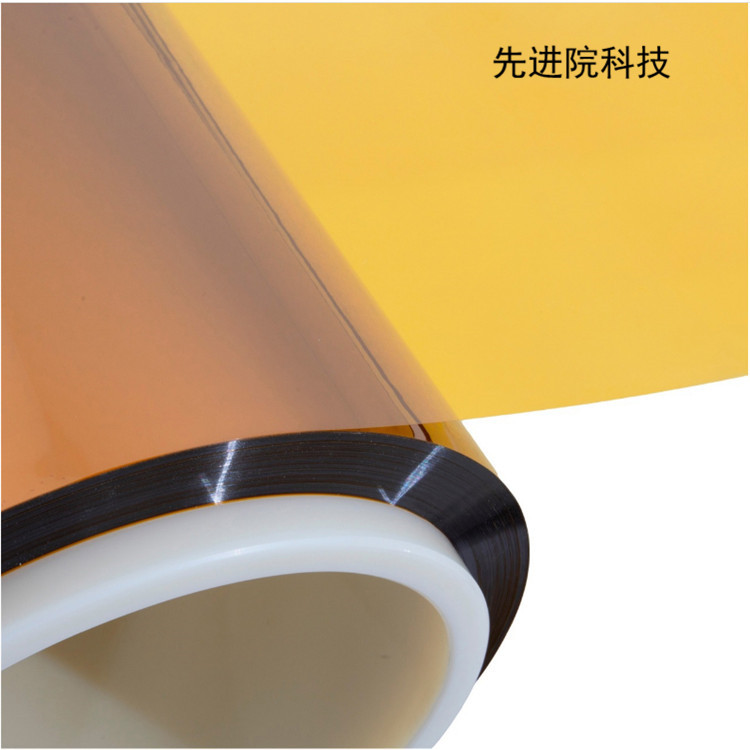

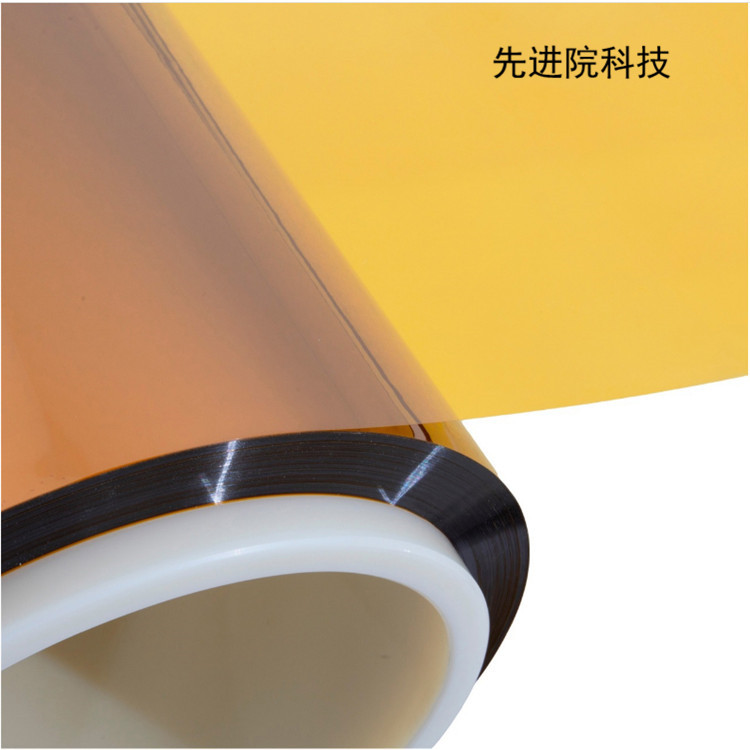

Micro porous aluminum foilIt refers to the surface microstructure of aluminum alloy foil obtained after special treatment, which presents a porous shape. The morphology and size of this microstructure can be controlled by process parameters to achieve certain air permeability and conductivity. Its main characteristics are high specific surface area and porosity, and the ability to control the size and shape of pores, which can meet the requirements of battery conductivity and safety.

2、 Preparation method of microporous aluminum foil

At present, the preparation methods of microporous aluminum foil mainly include chemical corrosion method, electrochemical corrosion method, passivation method, etc.

1. Chemical corrosion method

The chemical corrosion method uses one or more acidic or alkaline solutions to control the surface microstructure and porosity of the obtained alloy by adjusting process parameters such as temperature, reaction time, acidity, and concentration. The product produced by this method has a rough surface, high porosity, uniform distribution, and is suitable for making negative electrode current collectors for batteries.

2. Electrochemical corrosion method

The electrochemical corrosion method mainly uses the principle of electrochemistry to generate micropores on the surface of aluminum foil, which has the characteristics of high controllability, small porosity, and uniform pore size, and is suitable for making battery positive electrode current collectors.

3. Passivation method

Passivation method is to attach passivating agents to the surface of aluminum foil, enhance the stability and corrosion resistance of the aluminum foil surface, avoid excessive corrosion of the aluminum foil surface, and control the pore characteristics.

3、 Characteristics of microporous aluminum foil

1. High specific surface area

Due to the presence of micrometer sized pores on the surface of aluminum foil, the specific surface area of microporous aluminum foil is much larger than that of ordinary aluminum foil, thereby improving the speed of molecular diffusion and the efficiency of electrochemical reactions.

2. Adjustable porosity

The porosity of microporous aluminum foil is adjustable, and can be controlled by changing the preparation method, process parameters, etc., in order to achieve differentiated application requirements.

3. Higher conductivity

The surface of microporous aluminum foil presents micrometer sized pores, which result in its good conductivity.

4. Have good ventilation

Due to its porous structure, the surface of microporous aluminum foil exhibits large through holes and good ventilation, which helps to facilitate the ventilation and excretion of gases inside the battery.

5. Good mechanical performance

Micro porous aluminum foil has good mechanical properties, can withstand high pressure, and is not easily deformed or broken.

4、 Application of microporous aluminum foil in lithium-ion batteries

1. Collecting fluid

Lithium ion battery is a complex system composed of multiple components such as negative electrode, separator, positive electrode, electrolyte, and current collector. The current collector plays an essential role in providing electronic conduction for the battery and is an indispensable part of the battery. The porosity of microporous aluminum foil can be controlled, and it has good conductivity and breathability, making it the best choice for current collector materials.

2. Electrolyte filtration

Microporous aluminum foil can also be used to make electrolyte filters. The microporous structure on its surface can filter the electrolyte, reduce impurities, metal ions, etc. in the electrolyte, thereby improving the purity and cycle life of the battery.

3. Conductive film

The high conductivity and pore structure of microporous aluminum foil make it not only suitable as a current collector for batteries, but also as a conductive thin film, which can be applied in new electronic devices.

In summary, microporous aluminum foil is an important material for lithium-ion batteries, characterized by high specific surface area, adjustable porosity, high conductivity, good ventilation, and good mechanical properties. It can be widely used in current collectors, electrolyte filtration, and conductive films of lithium-ion batteries, and has important application prospects.