Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

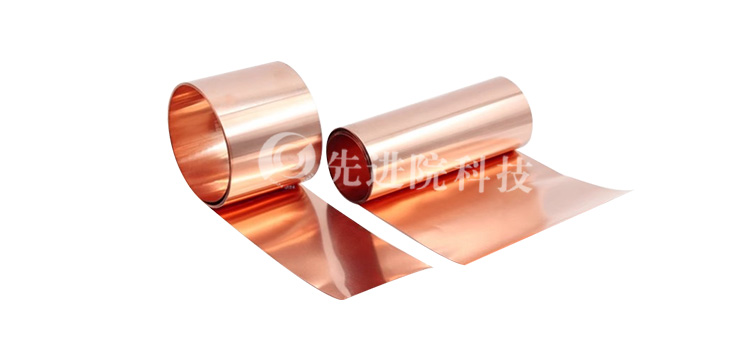

PP copper plated filmIt is a composite material that combines polypropylene (PP) substrate and copper coating, and has shown wide application potential in multiple high-tech and emerging fields due to its unique properties. This article will focus on analyzing the electrical insulation, heat resistance, corrosion resistance, and arc resistance of PP copper plated film, and introduce the innovative achievements of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field.

The electrical insulation of PP copper plated film mainly depends on the characteristics of its polypropylene substrate. Polypropylene, as a thermoplastic, has excellent electrical insulation properties. By coating a layer of copper on the PP substrate, this composite material increases its conductivity while maintaining its original electrical insulation properties. Although copper plating improves conductivity, PP copper plating film can still meet the electrical insulation requirements of many electronic components under appropriate thickness and process control.

Advanced Institute (Shenzhen) Technology Co., LtdBy optimizing the copper plating process, the uniform adhesion of the copper coating on the PP substrate is ensured, thereby maximizing the electrical insulation performance of the PP substrate while ensuring conductivity. This makes PP copper plated film have significant advantages in fields such as electromagnetic shielding, RFID tags, touch screen sensors, etc.

The heat resistance of PP copper plated film mainly depends on the thermal deformation temperature of the polypropylene substrate and the stability of the copper plated layer. The thermal deformation temperature of polypropylene is usually above 100 ℃, which enables PP copper plated films to maintain stable physical and chemical properties at higher temperatures. In addition, through advanced chemical copper plating technology and drying curing process, the PP copper plating film produced by Advanced Institute (Shenzhen) Technology Co., Ltd. has achieved good heat resistance on the copper plating layer and can maintain stable conductivity in high temperature environments.

In the field of new energy vehicles,PP copper plated filmThe application not only reduces the weight of key components such as battery management systems and motor controllers, but also optimizes the current transmission path and improves energy utilization efficiency. These applications all benefit from the excellent heat resistance of PP copper plated film.

The corrosion resistance of PP copper plated film is mainly due to the protection of its copper plating layer. Copper, as a relatively stable metal with chemical properties, has good corrosion resistance to most chemical substances. Through a special surface treatment process, the PP copper plating film of Advanced Institute (Shenzhen) Technology Co., Ltd. exhibits excellent chemical corrosion resistance, and can maintain stable electrical performance and structural integrity even under harsh environmental conditions.

This corrosion resistance makes PP copper plated film have a wide range of application prospects in the packaging industry, which can be used to make anti-counterfeit labels and intelligent packaging with conductive properties, improving product safety and traceability.

Arc resistance is the ability of a material to maintain its physical and electrical stability under the action of an arc.PP copper plated filmDue to the combination of its polypropylene substrate and copper coating, it usually exhibits good arc resistance performance. Under the combined effect of the insulation performance of polypropylene substrate and the conductivity of copper coating, the PP copper plating film can maintain low resistivity and high electrical strength under arc action.

Advanced Institute (Shenzhen) Technology Co., Ltd. has further improved the arc resistance of PP copper plated films by optimizing production processes and controlling the thickness of copper plating layers. This makes PP copper plated film have broad application potential in high-voltage electrical appliances, power electronics and other fields.

PP copper plated filmWith its unique electrical insulation, heat resistance, corrosion resistance, and arc resistance, it has shown great potential for application in multiple high-tech and emerging fields. Advanced Institute (Shenzhen) Technology Co., Ltd. has produced PP copper plated film products with excellent performance by optimizing production processes and copper plating technology, meeting the market's demand for high-performance composite materials.

With the continuous advancement of technology and the expansion of the market, PP copper plated film is expected to play an important role in more fields, promoting innovation and development in related industries. Advanced Institute (Shenzhen) Technology Co., Ltd. will continue to be committed to the research and innovation of materials technology, bringing more innovative products and technological solutions to various industries.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2