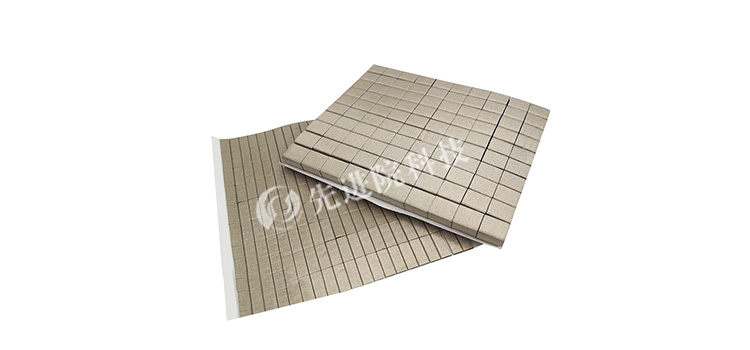

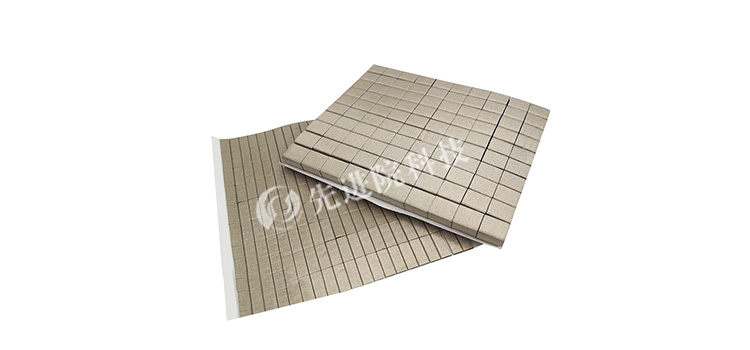

In the design and manufacturing process of electronic products, selecting appropriate conductive foam materials is crucial to ensure the electromagnetic compatibility (EMC), electromagnetic shielding (EMI), and anti-static (ESD) performance of the product.Copper plated nickel flat woven conductive foamDue to its excellent conductivity and shielding effect, it stands out among many conductive materials. This article will combine the actual situation of Advanced Institute (Shenzhen) Technology Co., Ltd. and Yanbo brand copper nickel flat woven conductive foam to explore how to choose suitable conductive foam according to the specific needs of electronic products.

1、 Understand the basic technical parameters of conductive foam

Before choosing copper nickel flat woven conductive foam, it is necessary to first understand its basic technical parameters, including:

- Shielding effectiveness: measures the shielding ability of conductive foam against electromagnetic waves, usually expressed in decibels (dB). The shielding effectiveness of high-quality conductive foam should be ≥ 90dB.

- Surface resistance: Refers to the electrical conductivity of the surface of conductive foam, measured in ohms per square meter (Ω/㎡). The surface resistance of copper nickel flat woven conductive foam should usually be ≤ 0.05 Ω/㎡.

- Temperature of use: Performance of conductive foam at different temperatures. For example,Yanbo brand copper nickel flat woven conductive foamThe temperature range for use is -40 ℃ to 80 ℃.

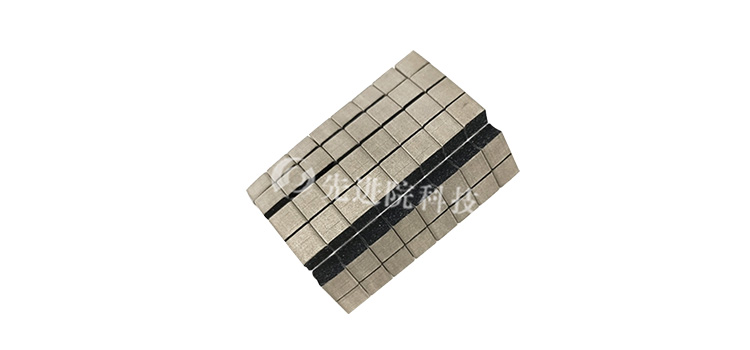

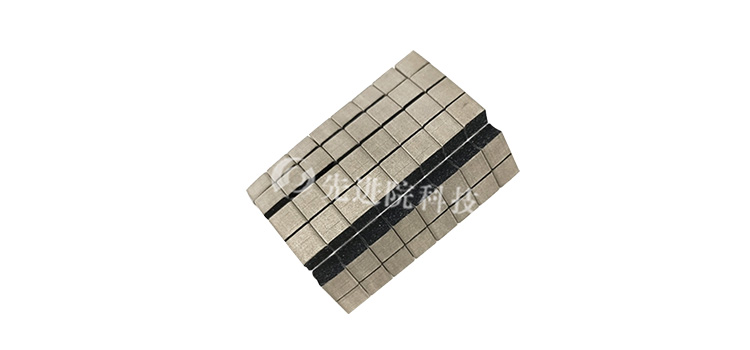

- Compression deformation: The degree of deformation of conductive foam under pressure affects its stability and conductivity in applications. The ideal compression deformation should be between 3% and 10%.

- Flame retardancy: The fire resistance of conductive foam must comply with international standards such as UL94-VO.

2、 Choose the appropriate conductive foam according to the requirements of electronic products

- Conductivity requirements:

- For applications that require high conductivity, such as the shielding overlap between CPU heat sinks and metal shells, copper nickel flat woven conductive foam with low surface resistance and stable conductivity should be selected. The conductive performance of Yanbo brand copper nickel flat woven conductive foam is excellent, with a surface resistance of ≤ 0.05 Ω/㎡, suitable for grounding high-frequency noise.

- Shielding effectiveness requirements:

- In applications that require high shielding effectiveness, such as laptops, desktop PCs, and other consumer electronics products, conductive foam with a shielding effectiveness of ≥ 90dB should be selected for electrostatic discharge protection and radiation shielding of I/O ports.Advanced Institute (Shenzhen) Technology Co., LtdThe copper plated nickel flat woven conductive foam provided has excellent shielding performance, which can effectively prevent external interference noise from entering the internal circuit and prevent internal radiation noise from leaking through the port.

- Compression performance requirements:

- The components in electronic products are usually fragile and require conductive foam with good compression performance to protect them from damage. Copper plated nickel flat woven conductive foam has good elasticity and can quickly recover and maintain its original shape under pressure, providing effective cushioning and protection.

- Flame retardant performance requirements:

- In applications that require high flame retardant performance, such as military equipment, aerospace equipment, etc., conductive foam that meets international standards such as UL94-VO should be selected. Yanbo brand copper nickel flat woven conductive foam has UL level fire resistance, which can effectively prevent the occurrence of fires.

- Structural dimension requirements:

- Different electronic products have different requirements for the structural dimensions of conductive foam. When selecting conductive foam, the appropriate length, width, and height should be chosen according to the actual application scenario. Height selection is particularly important, as an inappropriate height may result in suboptimal conductivity of the conductive foam.

3、 Case analysis and practical application

Taking laptops as an example, the heat sink of the CPU chip is an important path for high-frequency noise interference coupling emission, and the overlap gap between the heat sink and the metal shell is also the main way for high-frequency noise leakage. By adding copper nickel flat woven conductive foam between the CPU heat sink and the metal shell, not only can the spatial radiation of the heat sink itself be effectively reduced, but also the problem of gap leakage can be solved, improving the electromagnetic compatibility of laptops.

4、 Summary

Choose the appropriate oneCopper plated nickel flat woven conductive foamIt is crucial to ensure the electromagnetic compatibility, electromagnetic shielding, and anti-static performance of electronic products. When selecting, factors such as conductivity, shielding effectiveness, compression performance, flame retardancy, and structural dimensions should be comprehensively considered, combined with the actual needs of electronic products for selection. Advanced Institute (Shenzhen) Technology Co., Ltd. and Yanbo brand copper nickel flat woven conductive foam have become the preferred materials for many electronic product manufacturers due to their excellent performance and wide application fields.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.