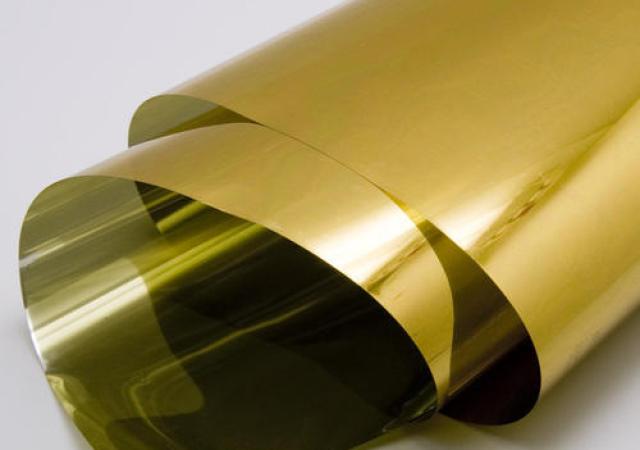

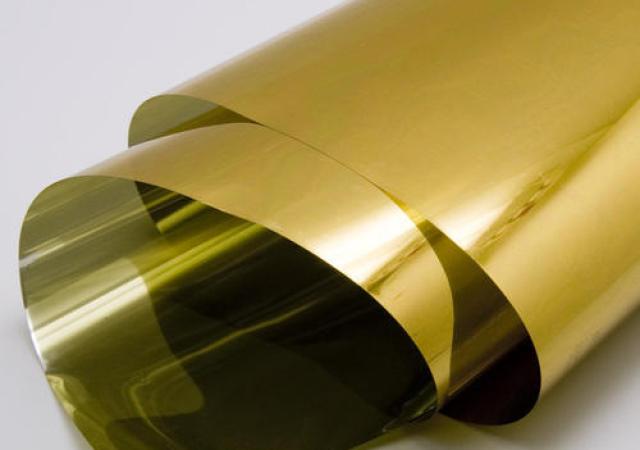

Foam copper tin alloyIt is a light metal, usually composed of copper and tin, with good conductivity, thermal conductivity, corrosion resistance and other properties. It is an alloy with the ability to develop cold solidification, high strength and toughness, suitable for manufacturing various precision parts and mechanical products.

The main components of foam copper tin alloy are copper and tin, and the content is about 60%~80%. It is a single component alloy that does not contain any other metallic elements, so there is no contamination from corrosive substances. The structure of foam copper tin alloy is relatively simple, which is composed of copper matrix and tin matrix, and has good corrosion resistance. At high temperature, foam copper tin alloy will not be damaged due to oxidation or corrosion, and has high durability.

Foam Cu Sn alloy has good electrical conductivity, thermal conductivity, corrosion resistance and thermal fatigue resistance.

1. The following are some characteristics and application scenarios of foam copper tin alloy:

High conductivity: foam copper tin alloy has good conductivity and can maintain good conductivity in a wide temperature range.

Excellent thermal conductivity: foam copper tin alloy has high thermal conductivity, which can transfer heat in time and improve the heat dissipation efficiency of equipment.

Corrosion resistance performance:

Foam copper tin alloyHas high corrosion resistance, can resist the erosion of corrosive media, and extend the service life of equipment.

Heat fatigue resistance: foam copper tin alloy has high heat fatigue resistance, and can maintain its strength and shape at high temperatures.

Wide application range: foam copper tin alloy is widely used in manufacturing electronics, electrical, machinery and other fields, such as switches, keys, motors, etc.

2. The forming process of foam copper tin alloy is relatively simple, and the main steps are as follows:

Preparation materials: Prepare copper wire, tin wire, coolant, and other materials.

Preparation of foam copper tin alloy ingot: put the copper wire into the ingot casting machine, add a certain amount of tin wire, coolant, etc., mix evenly, control the size and shape of the ingot, and obtain the required ingot billet.

Melting and casting: Place the ingot into the melting furnace and obtain the desired alloy solution through the melting and casting process.

Cooling and solidification: Cool the alloy solution to room temperature to avoid cracking or deformation during the cooling process.

Stretching and bending: Evaluate the mechanical properties of alloys, such as strength, toughness, stiffness, etc., through stretching and bending tests.

The foam copper tin alloy has simple manufacturing process and high production efficiency, and is suitable for the manufacturing of small and micro parts. In actual production, appropriate materials and processes can be selected according to specific conditions to obtain high-quality and high-performance foam copper tin alloy products.

In general, foam copper tin alloy is a new type of metal material with many excellent properties, which has important application value in manufacturing high reliability, high precision and long life. When making a selection, it is necessary to choose based on specific circumstances to ensure that the quality and performance of the product meet the requirements. In addition, it is necessary to understand relevant standards and specifications in order to better control the quality and safety of products.