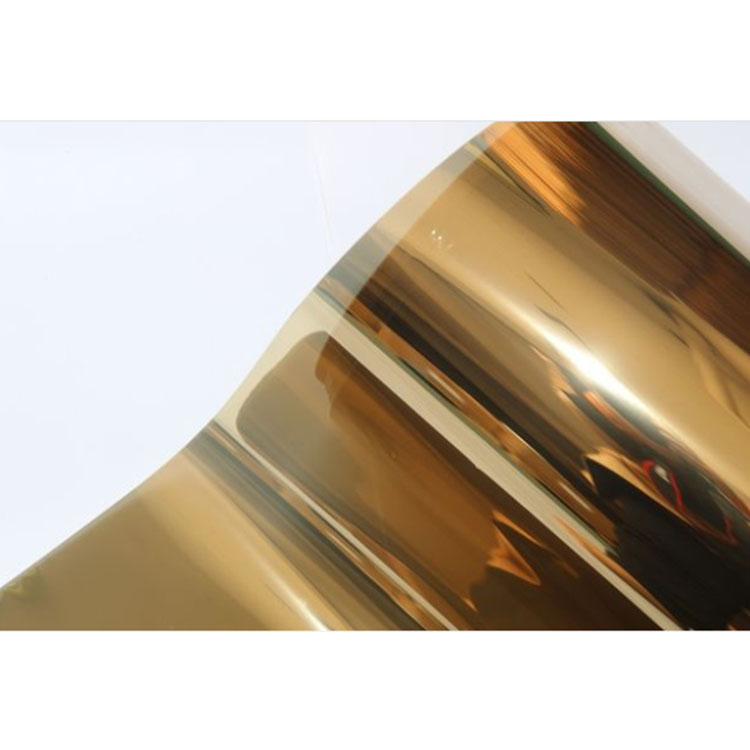

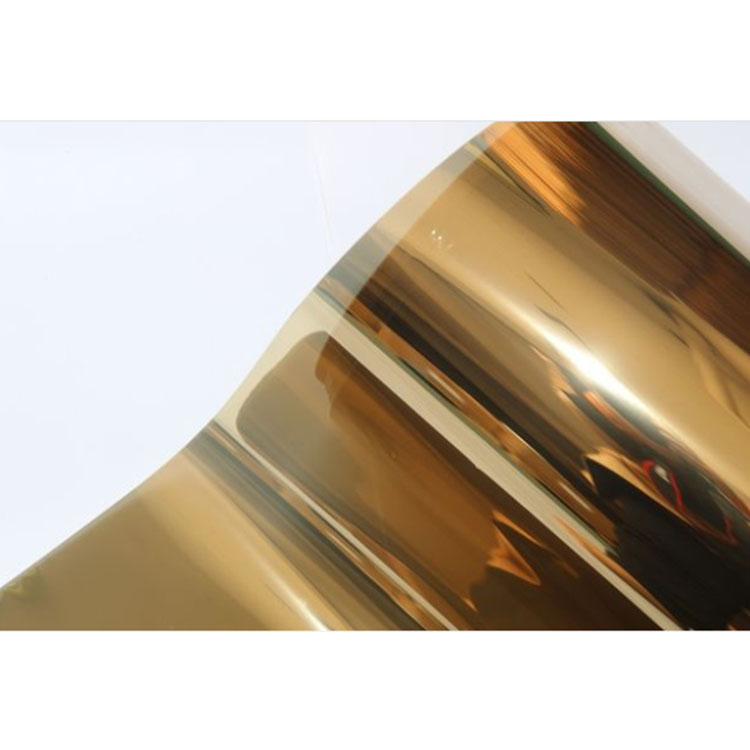

Nickel plated copper alloy is a metal material with good conductivity, high temperature resistance, corrosion resistance, and thermal conductivity. It is an alloy coated with a layer of nickel or copper on a metal surface, usually prepared by electroplating or hot-dip coating.

1、 The process principle of nickel plated copper alloy:

1. After annealing pure copper or brass plates, followed by acid washing to remove dirt, and then cleaning and drying, the substrate surface is treated with a mixture of ferrous sulfate solution and ammonium chloride solution in a heating furnace. By thermal decomposition, an oxide film is formed on the surface of the substrate, and a dense protective film is formed. Due to the higher corrosion resistance of the metal substrate treated by this method compared to chemical conversion method, this method is called "physical conversion method". This method is currently the most widely used method.

2. Prepared by chemical conversion method. Firstly, the pure copper or brass plate is annealed, then acid washed to remove dirt, and then soaked in alkaline water (NaOH) to remove surface oil stains. Finally, it is soaked in dilute hydrochloric acid to remove residual chloride ions on the metal surface. In this way, a thin and dense protective film can be formed on the metal surface, thereby improving its corrosion resistance. This method is currently widely used.

2、 Coating thickness and composition:

(1) According to different purposes, different thicknesses of coatings are generally selected. If used for protection, a 0.5-1mm thick coating can be selected; For decoration, a 1-2mm thick coating can be selected.

(2) Choose coatings with different compositions and thicknesses based on the usage environment. If used for corrosion prevention in seawater, a zinc based (Zn Cr Mo) composite type with a chromium content greater than 10% should be selected, where the Zn content is 40-50%, the Cr content is 8-12%, and the Mo content is 3-5%.

(3) According to the usage requirements, it can also be produced according to customer requirements.

(1) Has excellent corrosion resistance. When the temperature is above 600 ° C, it can still maintain good corrosion resistance.

(2) Has good processability and weldability.

(3) Has good extensibility.

(4) Has excellent wear resistance.

4、 The advantages of nickel plated copper alloy include:

High conductivity: The conductivity of nickel plated copper alloy is usually much higher than other metal materials, so it can effectively shield electromagnetic waves and electromagnetic interference.

High temperature resistance: Nickel plated copper alloys typically have much higher heat resistance than other metal materials, allowing them to maintain good performance in high-temperature environments.

Corrosion resistance: Nickel plated copper alloys typically have good corrosion resistance, which can prevent damage due to corrosion during long-term use.

Thermal conductivity: Nickel plated copper alloy usually has better thermal conductivity than other metal materials, which can improve the heat exchange capacity of equipment.

Application areas: Nickel plated copper alloys have a wide range of applications in many fields, such as electronic devices, power systems, aerospace, etc. It plays an important role in improving the heat exchange capacity of equipment and heat exchangers. In addition, nickel plated copper alloy can improve the wear resistance, abrasion resistance, and corrosion resistance of equipment, making it suitable for various environments.