Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

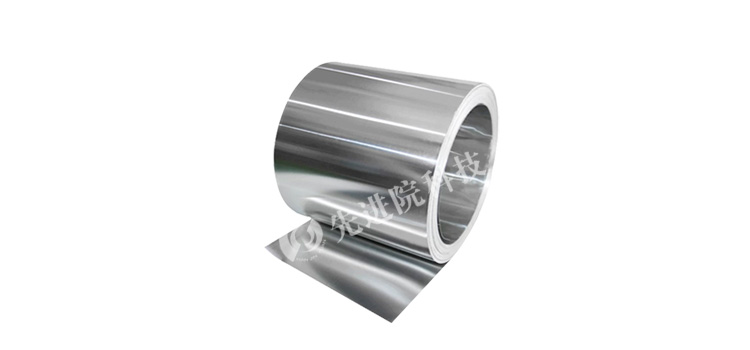

In the fields of modern technology and materials science, silver plating technology is widely used in multiple industries such as electronics, optics, and healthcare. Especially in the field of flexible electronics and optical devices, silver plated PEN (Polyethylene Naphthalate) film has become one of the important materials due to its high transparency, high wear resistance, and excellent conductivity. This article will explore how the composition and ratio of silver plating solution affect itPEN silver plated filmThe manufacturing of the product, with special mention of the application of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field.

Silver plating solution is usually composed of soluble silver salts, complexing agents, additives, acids, surfactants, brighteners, and pH adjusters. Here are some key components and their functions:

The concentration ratio of each component in the plating solution directly affects the quality and conductivity of the silver plating layer

In the manufacturing process of PEN silver plating film, the composition and ratio of silver plating solution directly affect the quality and conductivity of the coating, which in turn affectsPEN silver plated filmOverall performance:

Advanced Institute (Shenzhen) Technology Co., Ltd. specializes in thermal conductive materials, shielding materials, and conductive pastesFlexible electrode materialWe have rich research and production experience in fields such as conductive silver paste. The PEN silver plated film provided by the company has high transparency, high wear resistance, and excellent conductivity, and is widely used in fields such as flexible electronics and optical devices.

In the manufacturing process of PEN silver plated film,Advanced Institute (Shenzhen) Technology Co., LtdPay attention to optimizing the composition and ratio of silver plating solution to ensure the high quality and conductivity of the coating. Through advanced production processes and strict quality control, the company is able to provide high-quality PEN silver plated films that meet customer needs.

In summary, the composition and ratio of silver plating solution play a crucial role in the manufacturing process of PEN silver plating film. By optimizing the composition and ratio of silver plating solution, the quality and conductivity of the coating can be improved, thereby enhancing the overall performance of PEN silver plating film. Advanced Institute (Shenzhen) Technology Co., Ltd. has rich experience and technological advantages in this field, providing customers with high-quality products and services.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2