The development of microwave technology has increasingly high requirements for filters, and microwave ceramic filters, as a commonly used filter, have silver paste as their dedicated electrode material.

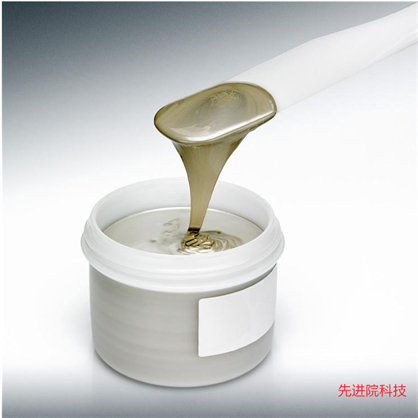

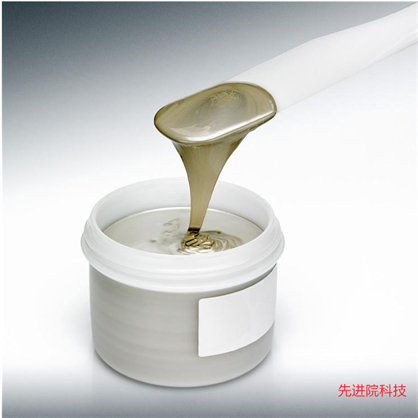

YB-5022 silver pasteIt is made from materials such as silver powder, glass powder, resin, solvents, and additives. It has excellent printing performance and outstanding electrical performance, suitable for double-sided printing electrodes of ceramic components. In addition, YB-5022 silver paste is non-toxic and harmless, meeting environmental protection requirements.

1、 Advantages and characteristics of silver paste

1. Excellent printing performance

YB-5022 silver paste has high viscosity and can be printed smoothly through screen printing. Its viscosity is 30 ± 120Pa.s/25 ℃, and it can flow stably during the printing process, ensuring the uniform coating of silver paste. In addition, the fineness of the silver paste (paste fineness) is also very important. The fineness of YB-5022 silver paste is less than 10um, ensuring the smoothness and fineness of the printed product.

2. Excellent electrical performance

High Q value and low loss are important indicators of microwave ceramic filters, and YB-5022 silver paste can meet these requirements. The electrode film layer formed on ceramic components is uniform and has strong adhesion, providing stable electrical performance. Through appropriate printing and sintering conditions, YB-5022 silver paste can achieve high conductivity and low resistivity, ensuring high-performance operation of the filter.

3. Environmentally friendly and harmless

An important environmental requirement in the production process of silver paste is the absence of harmful substances. YB-5022 silver paste fully complies with environmental standards such as RoHS and REACH, does not contain harmful substances such as lead and cadmium, and is safe and reliable to use. This is a very important guarantee for the application scenarios of filters and the health of users.

1. Screen printing

YB-5022 silver pasteThe screen printing is suitable for grids of 200-325 mesh. Choose the appropriate grid for printing according to the needs, usually using finer screens can achieve finer printing effects.

2. Drying conditions

After printing, place the printed ceramic components in a hot air drying oven for drying. The recommended drying conditions are 150-200 ℃ for 3-5 minutes. By appropriate temperature and time, silver paste can be completely cured and adhered during the drying process.

3. Sintering conditions

Before sintering, it is necessary to control the sintering conditions appropriately. The recommended sintering conditions for YB-5022 silver paste are Ttop 850 ℃ for 10 minutes. The actual sintering temperature can be adjusted according to specific requirements to achieve the required electrical performance and stability of the filter.

YB-5022 silver pasteAs a specialized electrode material, it provides important support for high-frequency microwave ceramic filters. It has excellent printing and electrical performance, while also meeting environmental requirements, non-toxic and harmless. By strict usage methods and appropriate process conditions, the efficient use of YB-5022 silver paste in filter manufacturing can be ensured. The application prospects of microwave ceramic filters in communication, radar and other fields are broad, and the emergence of YB-5022 silver paste will undoubtedly bring better possibilities and choices for the research and application of filters.