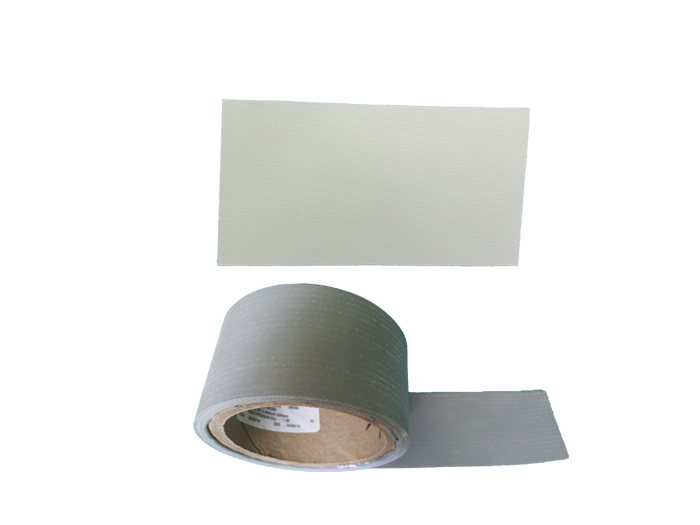

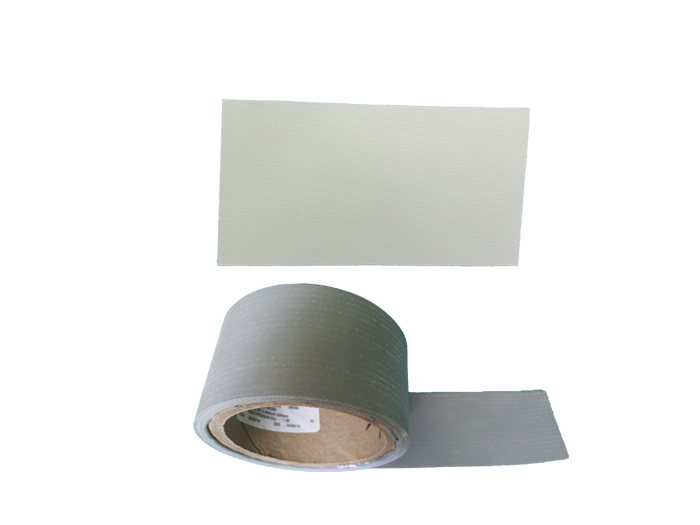

Conductive shielding filmIt is a thin film material used to block electromagnetic waves, which can effectively block external electromagnetic waves and resist interference, thus protecting internal electronic components from external interference. The main raw materials for conductive shielding film are aluminum foil and copper foil, which are covered with a layer of polystyrene (PET) film on their surfaces to provide good electrical insulation and heat resistance. The production process of conductive shielding film is to first treat the surface of the metal foil, then cover it with a layer of polystyrene film, and finally perform heat treatment to form the final conductive shielding film. Conductive shielding film has the advantages of good electrical insulation, heat resistance, corrosion resistance, and arc resistance, and is therefore widely used in the packaging of electronic devices, chip packaging, and sensor manufacturing. Conductive shielding film has excellent thermal stability, which can effectively resist the effects of high and low temperatures, suppress the deformation and damage of electronic components, and thus improve the reliability of electronic components.

In addition,

Conductive shielding filmIt also has good corrosion resistance, which can effectively prevent corrosion of metal surfaces and significantly improve the service life of electronic components.

Shielding film is applied in industries such as 5G communication and automotive electronics. In the 5G environment, the trend of lightweight, short, high-frequency and high-speed electromagnetic shielding film products in consumer electronics, represented by smartphones, is becoming increasingly evident. The use of internal structure FPC is constantly increasing to improve the internal assembly density. At the same time, electromagnetic interference between electronic components is becoming more serious, which objectively increases the demand for electromagnetic shielding film. This demand is reflected on the one hand in the increase of electromagnetic shielding film usage, and on the other hand in the requirements for improving the performance of electromagnetic shielding film (such as thinner thickness, higher shielding effectiveness, lower insertion loss, stronger bending resistance, stronger tear resistance, etc.)

In short,

Conductive shielding filmIt is a very practical technology that can effectively block external electromagnetic waves and resist interference, thereby protecting internal electronic components from external interference. Its application can significantly improve the reliability and stability of electronic components, making it a very practical technology. Therefore, conductive shielding film technology is expected to have greater development and application in the future.