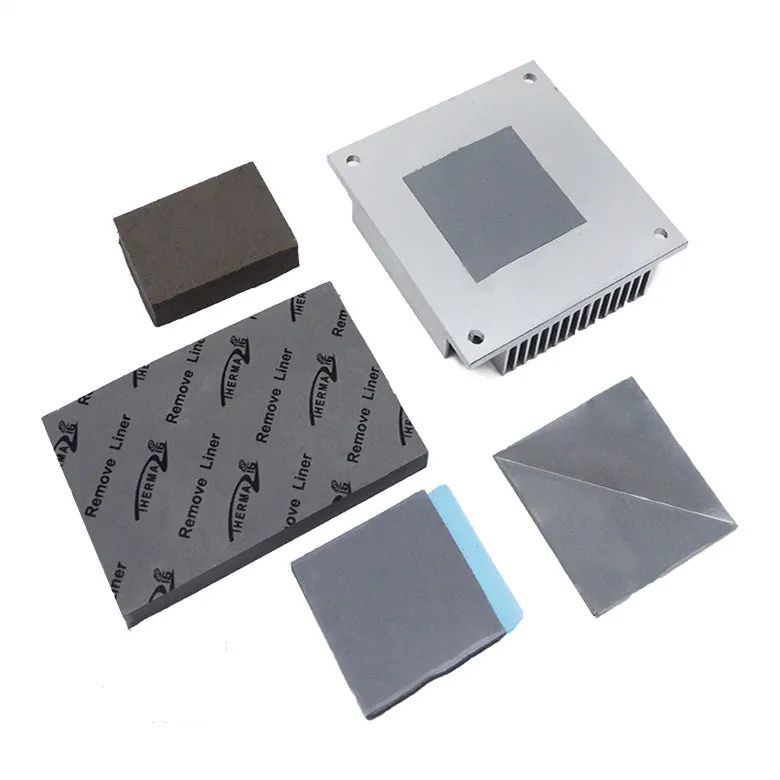

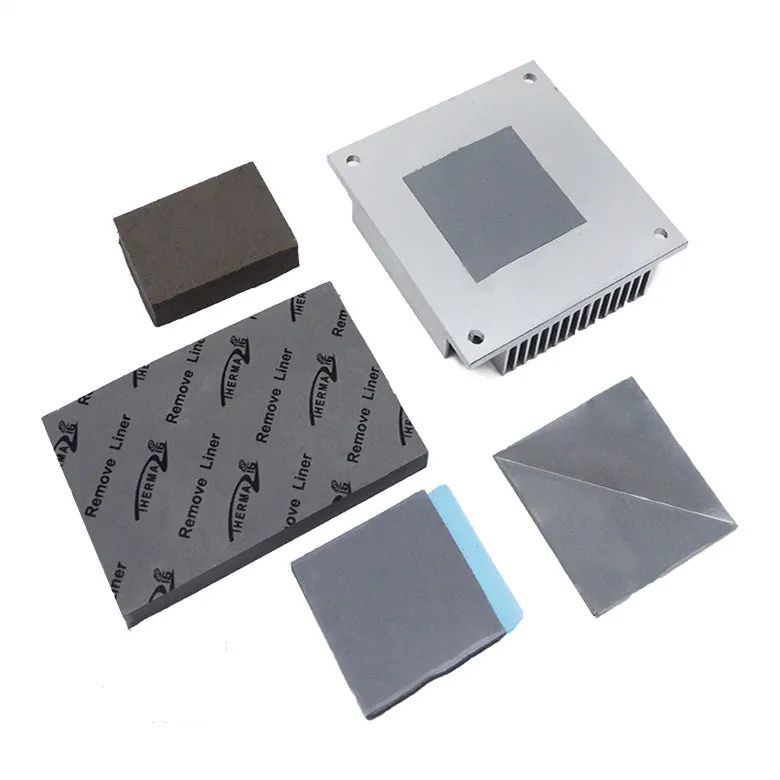

conductive rubberIt is a conductive material formed by dispersing granular fillers, oriented metal wires, embedded metal wire mesh or expanded metal in dense or sponge like elastic bodies. They have good conductivity and sealing properties, and can be widely used for electromagnetic interference sealing, pressure, environmental sealing and other purposes.

Conductive rubber can be used in electronic shielding products that resist electromagnetic interference. Usually, the shielding system includes a sandwich conductive gasket between the metal component and the shell. The main function of the gasket is to provide high conductivity between the joint surface of the shell/gasket/cover to meet grounding and other requirements

Electromagnetic ShieldingTo meet the requirements and prevent external interference from entering electronic components.

Conductive rubber gasket is a type of rubber gasket with high conductivity, usually made of high elastic rubber material, which can effectively prevent electromagnetic interference and protect electrical systems from damage.

The following is a comprehensive introduction to conductive rubber gaskets:

Conductive rubber gasketThe main components are rubber and metal oxides. Among them, rubber is a material with good elasticity and oil resistance, while metal oxide is a material with conductive properties. There are many types of metal oxides, such as aluminum oxide, zinc oxide, magnesium oxide, etc.

The main application areas of conductive rubber gaskets include electrical system connections, electrical insulation, sealing, etc. In these fields, conductive rubber gaskets have a wide range of applications. Such as electrical insulation in electrical system connections, sealing in high-voltage electrical equipment, and connection of high-voltage transmission lines. The main performance parameters of conductive rubber gaskets include electrical resistivity and tensile strength. Electrical resistivity refers to the magnitude of the resistance of a conductor at a certain temperature and voltage. Tensile strength refers to the strength that a conductor possesses when it fractures under a certain stress.

Conductive rubber gaskets can be made of various materials, such as natural rubber, styrene butadiene rubber, chlorosulfonated polyethylene, polyurethane, etc. Different materials have different properties and characteristics, such as electrical resistivity, tensile strength, flexibility, wear resistance, etc.

When selecting conductive rubber gaskets, it is necessary to consider the material properties and application scenarios. Different conductive rubber gaskets have different properties and characteristics, such as resistivity, tensile strength, flexibility, etc., which need to be selected according to specific application scenarios. At the same time, it is also necessary to consider issues such as material costs and environmental protection.

so

Conductive rubber gasketIt is a rubber gasket with high conductivity and excellent characteristics, which has a wide range of application prospects and important value. When selecting conductive rubber gaskets, it is necessary to choose according to specific application scenarios and requirements to ensure that the material's performance and quality meet the requirements and ensure its effectiveness in practical applications.