1、 Diversified application fields of platinum alloy catalytic mesh

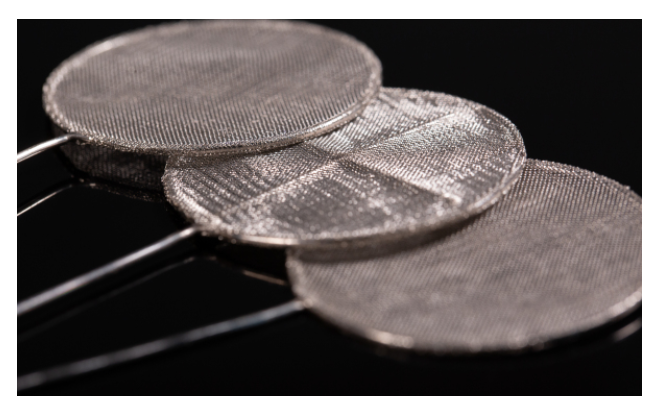

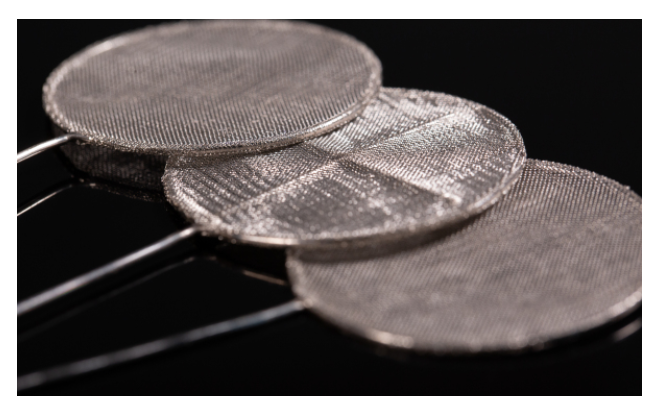

Platinum alloy catalytic meshAs an important catalytic material, it is widely used in the production processes of nitric acid and hydrogen cyanide. Its superior physical and chemical properties make it an ideal choice for preparing these chemicals.

1. Catalytic activity for preparing nitric acid

Nitric acid, as an important chemical raw material, is widely used in industries such as fertilizers, explosives, dyes, and pesticides. The platinum alloy catalytic mesh plays an irreplaceable role in the preparation of nitric acid. Catalytic mesh can promote rapid reaction between oxygen and ammonia to generate nitrogen oxides under limited temperature and pressure. This reaction has the characteristics of high efficiency, speed, and controllability, which can significantly improve the yield and purity of nitric acid.

The importance of preparing hydrogen cyanide acid

Cyanuric acid plays an important role in the synthesis of vitamin C, insecticides, and dyes. The application of platinum alloy catalytic mesh in the preparation of hydrogen cyanide acid is also indispensable. Platinum alloy catalytic mesh can catalyze the oxidation of ammonia and methane to produce hydrogen cyanide at lower temperatures and pressures. This reaction has high efficiency and good selectivity, which not only increases the yield of hydrogen cyanide, but also reduces energy consumption and environmental pollution.

2、 Diversified product specifications for platinum alloy catalytic mesh

In order to meet different process requirements, the product specifications of platinum alloy catalytic mesh are diversified, including plain weave mesh, knitted mesh, multi-layer mesh, and SMC mesh. In addition, different platinum alloy components also exhibit their own unique catalytic properties.

1. PtRh5: Excellent corrosion resistance

PtRh5 is a platinum alloy catalytic mesh with a rhodium content of 5%. Its main feature is its extremely high corrosion resistance and ability to work stably in harsh environments. Therefore, PtRh5 is widely used in the preparation of processes such as nitric acid and hydrogen cyanide, which can maintain the long lifespan and high efficiency of the catalytic network.

2. PtRh7: Excellent thermal stability performance

PtRh7 is a platinum alloy catalytic mesh with a rhodium content of 7%. Its uniqueness lies in its excellent thermal stability and ability to maintain catalytic performance even at high temperatures. This makes PtRh7 an ideal choice for specific process conditions, such as the preparation of cyanuric acid at high temperatures.

3. PtRh10: Excellent catalytic activity

PtRh10 is a platinum alloy catalytic mesh with a rhodium content of 10%. Its characteristic is excellent catalytic activity, which can efficiently catalyze the preparation reaction of nitric acid and hydrogen cyanide acid. Platinum rhodium 10 has a wide range of applications and is widely used in the preparation of high-purity nitric acid and hydrogen cyanide acid.

4. PtPdRh4-3.5: Synergistic effect of multicomponent alloys

PtPdRh4-3.5 (platinum palladium rhodium) is a multi-element alloy catalytic network containing three elements: platinum, palladium, and rhodium. The synergistic effect between different metal elements enables the catalytic network to have higher catalytic activity and selectivity. This makes PtPdRh4-3.5 an ideal choice for the preparation of specific specialty chemicals, such as functional dyes.

3、 Prospect of Platinum Alloy Catalytic Network

Platinum alloy catalytic mesh plays an irreplaceable role in the preparation of chemical processes such as nitric acid and hydrogen cyanide. With the increasing demand for raw materials in various industries, the demand for platinum alloy catalytic mesh will also continue to rise. In the future, people will continue to develop new platinum alloy catalytic networks to meet different process requirements and further improve catalytic performance and stability.

to make a long story short,

Platinum alloy catalytic meshAs an important catalytic material, it has a wide range of application fields and diverse product specifications. Its unique role in the preparation of chemical processes such as nitric acid and hydrogen cyanide has made it a focus of attention for engineering technicians and researchers. In the future, platinum alloy catalytic mesh will provide more possibilities for efficient production in various industries through continuous innovation and development.