Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

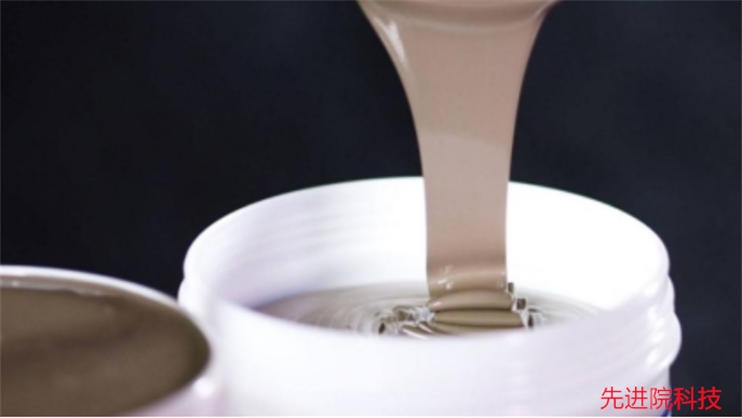

Conductive nickel pasteIt is a material commonly used in the production of multilayer ceramic capacitors (MLCC), which not only provides excellent conductivity, but also solves some problems in the manufacturing process. This article will delve into the unique contribution of conductive nickel paste used in MLCC, specifically addressing the concerns of readers.

1、 Solving the problem of agglomeration of nanoscale nickel powder

During the manufacturing process, nanoscale nickel powder is prone to agglomeration, which affects its conductivity. However, MLCC cleverly solved this problem with conductive nickel paste. By adding additives with good dispersibility, conductive nickel paste can maintain good dispersibility, ensuring that nickel powder is evenly distributed throughout the material, thereby improving the stability of conductivity. In addition,Conductive nickel pasteThe stability also helps to improve the reliability of MLCC products.

For example, the screen printed NPO series nickel internal electrode conductive paste developed by a certain research team has successfully achieved good dispersibility and stability in addressing process pain points such as nanoscale nickel powder agglomeration and electrode discontinuity. By carefully adjusting the combination of additives, the uniform distribution of nickel powder in the material has been achieved, resulting in a significant improvement in the conductivity of MLCC components.

In the process of MLCC, the sintering process of the inner electrode can easily lead to problems such as electrode discontinuity and unevenness, which in turn affect the reliability and voltage strength of the component. And with the help ofConductive nickel paste for MLCCThis issue has also been effectively resolved.

By adding appropriate additives, the sintering characteristics of conductive nickel paste can be controlled, thereby achieving good sintering matching. The controllability of the shrinkage matching characteristics during the sintering process helps to reduce the internal stress of MLCC components, improve crack problems, and increase yield and reliability. In this way, the electrode continuity and flatness of MLCC components have been significantly improved.

For example, by adjusting the proportion of additives and sintering temperature, a research group successfully developed a conductive nickel paste for MLCC with good electrode continuity and flatness. The experimental results show that this nickel paste can achieve good adhesion with the dielectric layer, and the conductivity and shape after sintering meet high standards, thereby significantly improving the reliability and voltage resistance of MLCC components.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2