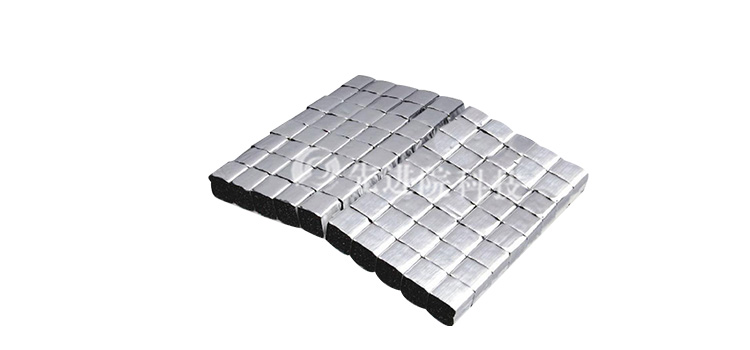

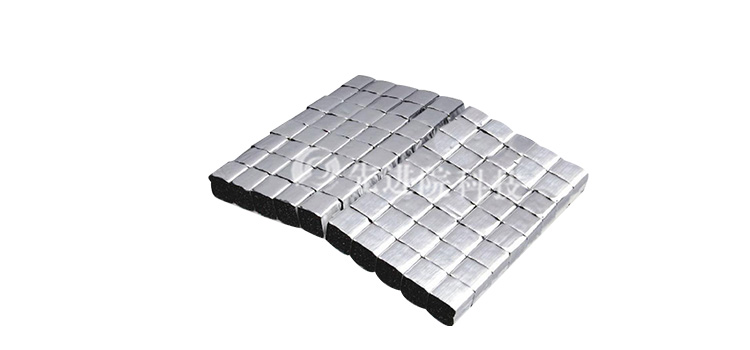

Aluminum foil foam, as a high-performance material, is widely used in fields such as microelectronics, semiconductors, aerospace, etc. The selection of its raw materials has a crucial impact on the quality and performance of the final product. This article will explore in detail the requirements for selecting raw materials for aluminum foil foam, and present the findings of Advanced Institute (Shenzhen) Technology Co., LtdYanbo brand aluminum foil foamFor example, conduct technical analysis.

1、 Requirements for raw material selection of aluminum foil foam

- Quality of aluminum foil

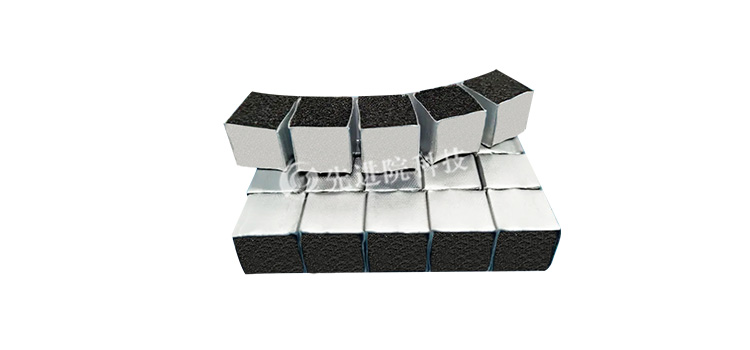

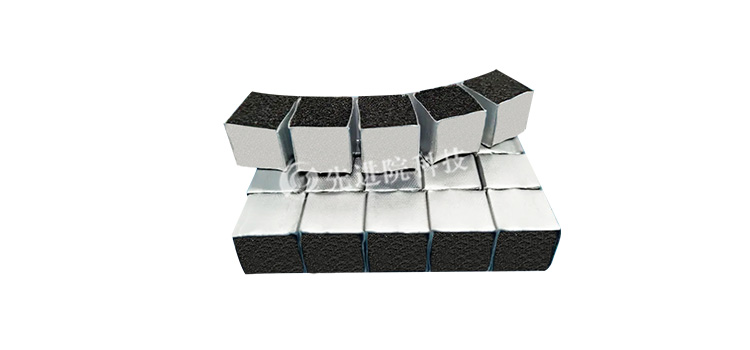

- Thickness and flatness: Using aluminum foil with moderate thickness and smooth surface as raw material can reduce wrinkles and unevenness during processing, ensuring the quality and appearance of the final product.

- Stability: Aluminum foil should have stable physical and chemical properties to resist interference from various environmental factors such as temperature and humidity during processing and use.

- Special treatment: To improve the wrinkle resistance of aluminum foil, it is possible to consider using aluminum foil that has undergone special treatment, such as adding a surface coating or performing other special treatments.

- Performance of glass fiber

- Strength and toughness: Glass fiber asAluminum foil foamOne of the composite materials should have high strength and good toughness to provide sufficient structural support and durability.

- Chemical stability: Glass fiber should have good chemical stability and be able to resist the erosion of chemical substances such as acid and alkali.

- Selection of flame retardant foam

- Flame retardant performance: Flame retardant foam should have good flame retardant performance to meet the safety requirements of different application scenarios.

- Density and Thermal Conductivity: The density and thermal conductivity of flame-retardant foam should be selected according to specific needs to ensure the thermal stability and insulation performance of the final product.

2、 Technical analysis of Yanbo brand aluminum foil foam

- Raw materials and manufacturing processes

- High quality aluminum foil:Yanbo brand aluminum foil foamUsing high-quality aluminum foil that has undergone special treatment as raw material, it has excellent wrinkle resistance and stability.

- Precision manufacturing: Using advanced production equipment and technology, such as precision molds, adjusting mold clearances, optimizing pressing methods, etc., to improve the manufacturing accuracy and flatness of aluminum foil foam.

- Performance characteristics

- Metal shielding performance: The surface impedance of the research platinum brand aluminum foil foam is ≤ 0.016 Ω, which has excellent shielding performance of metals and can meet the high requirements of electromagnetic shielding.

- Temperature resistance: Its temperature resistance can reach 130 ℃ and maintain stable performance in high temperature environments.

- High elasticity and corrosion resistance: The high elasticity design reduces the conductive impedance of the contact surface, improves the compatibility of the connector assembly metal coating, and has excellent corrosion resistance.

- application area

- Microelectronics and Semiconductors: Research Platinum brand aluminum foil foam is widely used in the fields of microelectronics and semiconductors, which can meet the requirements of high performance and high reliability.

- Aerospace: In the aerospace field, its stable connection state and excellent shielding performance provide strong guarantees for the normal operation of the system.

- Automotive electronics: The application of automotive electronic control units (ECUs) in high-temperature and vibration environments also demonstrates the excellent performance of Yanbo brand aluminum foil foam.

3、 Summary

The selection of raw materials for aluminum foil foam has a significant impact on the quality and performance of the final product.Advanced Institute (Shenzhen) Technology Co., LtdThe research platinum brand aluminum foil foam has produced aluminum foil foam products with excellent shielding performance, temperature resistance, and corrosion resistance by selecting high-quality aluminum foil, glass fiber, flame-retardant foam and other raw materials, and combining advanced manufacturing processes and technologies. These products are widely used in fields such as microelectronics, semiconductors, aerospace, and automotive electronics, providing strong support for the high-quality development of different industries.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.