Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

The preparation methods of metal film based conductive films are mainly divided into two categories: sputtering type and metal grid type, which are mainly used forTransparent electromagnetic shielding material.

Sputtering type refers to directly sputtering metal onto a substrate. Metal has good conductivity, but generally only when its thickness is less than 20nm, the absorption and reflection of light will greatly decrease, showing good transparency. However, if the film thickness is too low, a continuous film cannot be obtained, and the conductivity deteriorates. Therefore, due to its performance and cost limitations, the market application of this preparation process is limited.

Metal based transparent conductive films are mainly of the metal grid type, which can be further divided into etching method, fiber weaving method, printing method, and silver salt method. The printing method and silver salt method are new processes introduced in recent years for preparing transparent conductive films, which have the advantages of low cost, good flexibility, and adjustable surface resistance.

Oxide film based transparent conductive film

ITO film is currently one of the most widely studied and applied oxide transparent conductive thin films. Studies on the energy bands of In2O3 and SnO2 have shown that In2O3 and SnO2, which meet the stoichiometric ratio, are both wide bandgap insulators.

The mature methods for preparing flexible TCO transparent conductive films mainly include magnetron sputtering, vacuum evaporation, and ion plating.

However, each of these preparation methods has its own shortcomings, such as the complex equipment and high cost of sputtering methods, which are not suitable for large-scale industrial production.

Moreover, flexible substrates have poor high temperature resistance, which is not conducive to the growth of ITO films, resulting in higher resistivity of the prepared films. Therefore, further improvement is needed in the preparation technology of TCO films.

Polymer film series transparent conductive film

Conductive polymers are composed of some materials that have a common structure! Polymer materials formed by chemical or electrochemical doping of bonds, with conductivity extending from insulators to conductors.

Metal based composite multilayer conductive film

At present, there are mainly dielectric/metal/dielectric (D/M/D) and transparent conductive oxide/metal/transparent conductive oxide (TCO/M/TCO) composite multilayer films. At present, metal based composite multilayer conductive films still need improvement in terms of thermal stability and bonding strength with flexible substrates.

Carbon based composite conductive film

In October 2007, researchers from the Department of Science and Technology Development Engineering at the Union Institute of Advanced Technology at Tokai University in Japan announced the development of a carbon based composite conductive film using magnesium hydroxide as the main component.

The manufacturing process of this conductive film adopts RF magnetron sputtering method, which involves sputtering metal Mg and graphite at room temperature and low vacuum.

After forming a mixture film of Mg and C, simply place the film in a water vapor environment for 10-15 minutes, and H2O and Mg will slowly react, transforming the originally opaque film into transparent.

Although there are still issues such as low resistivity, substrate adhesion, resistance stability, and temperature dependence, it has the characteristics of low material cost and simple manufacturing process.

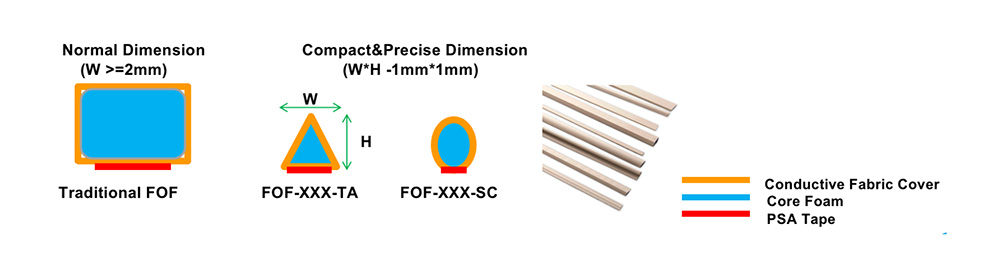

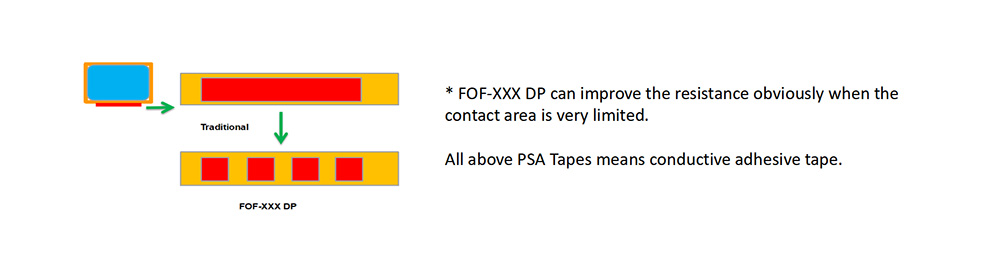

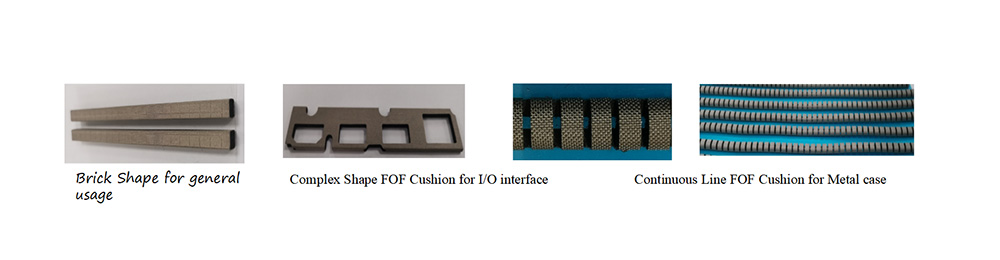

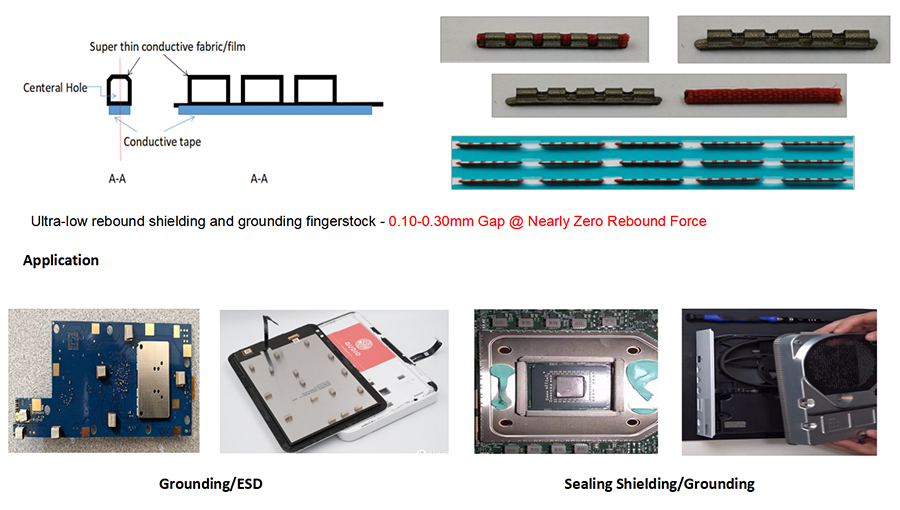

Basic structure of conductive foam&flexible film and composite conductive dense FOF cushion layer

Basic Structure and Composite Materials - Flexible Membrane Materials

Product matrix and material list

*All materials can be customized or specified according to customer requirements.

1、 Features and benefits

① High performance:

The shielding effect is 50dB across a wide frequency spectrum.

The shielding performance of wear-resistant metal fabrics has hardly decreased.

Low surface resistivity, up to 0.05 ohms/square depending on the fabric, ensuring good and stable grounding effect.

Extremely low compression force allows for the use of lighter materials

Long term reliability:

After environmental exposure, nickel/copper (Ni/Cu) fabrics showed no significant performance degradation according to the accelerated aging test (ASTM B845-93 Method H).

Polyurethane/soft polyurethane core provides low compression settings to ensure long-term reliability of gasket performance.

② Low cost:

• Easy to assemble with PSA

Compared to lower cost solutions, fasteners or spring clips are preferred over gold coatings.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2