Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

High performance electronic thermal conductive filmIt is a layered spatial structure film with high thermal conductivity and high heat resistance (400 ℃), which has excellent characteristics such as extremely high planar thermal conductivity, good flexibility, strong processability, and lightweight. Therefore, he is widely used in mobile phones, tablets LED、 Medical, aerospace, military industry and other fields. In practical applications, it can be processed into any shape according to the user's needs, and can also be compounded with other film materials such as PET and coated with glue according to the purpose. It can be used in many environments where conventional materials cannot be used. In the heat conduction process, the point heat source is quickly turned into a surface heat source, and the heat is quickly conducted to the dissipating heat components to prevent local overheating and failure of the heating components.

Product Features

Customization: The thickness can be customized within the range of 17 μ m to 100 μ m;

According to customer needs, it can be composite and processed with different backing adhesives, copper foil materials, etc;

Bending ability: gentle and durable, capable of withstanding 180 ° bending times>20000 times;

High thermal conductivity: The highest thermal conductivity can reach 1900W/mK.

Meet the RoHS directive.

Product Application

Widely used in smartphones, tablets, fanless design laptops, LED lighting equipment, medical equipment, new energy vehicle power batteries, etc.

Typical Product Structure

The typical structure of finished electronic thermal conductive film includes at least: protective film, single-sided adhesive, electronic thermal conductive film, double-sided adhesive, and release film;

The single-sided adhesive and double-sided adhesive are 1-2mm longer than the thermal conductive film, and the electronic thermal conductive film is double wrapped with single-sided and double-sided adhesive;

Each part of the finished electronic thermal conductive film can be customized according to specific customer needs;

Protective film and release film are materials used in the product process to provide protection, but they will be torn off during actual use.

Application effect

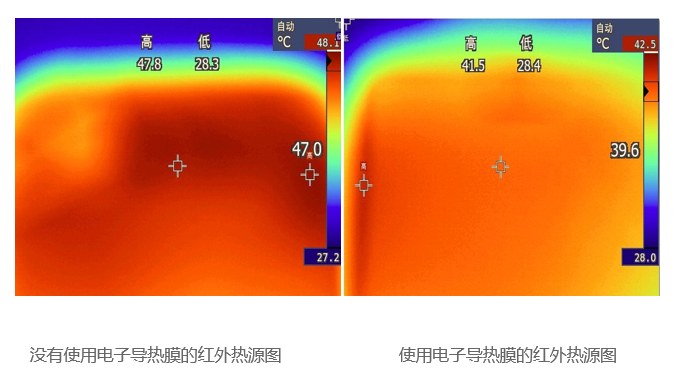

Heat source simulation test

Using a mobile phone for 15 minutes

It can be seen that mobile phones using electronic thermal conductive films have a rapid diffusion of point heat sources to surface heat sources, significantly reducing the temperature of the heating elementElectronic thermal conductive filmThe temperature of the phone is 7 ℃ lower than that of the phone without electronic thermal conductive film.

Specification parameters

| Product specifications |

40 |

25 |

17 |

Inspection standards |

||||||

| model |

A7 |

R2 |

D2 |

A2 |

R1 |

D1 |

A1 |

/ |

||

| Thickness/μ m |

40±5 |

25±2 |

25±2 |

25±2 |

17±2 |

17±2 |

17±2 |

ASTM D374 |

||

| Thermal diffusivity coefficient (cm2/s) |

7.5-8.5 |

7.5-8.5 |

8.0-9.0 |

8.5-9.5 |

7.5-8.5 |

8.5-9.5 |

8.5-9.5 |

ASTM E1461 |

||

| Specific heat (50 ℃)/(J/g · k) |

0.85 |

0.85 |

0.85 |

0.85 |

0.85 |

0.85 |

0.85 |

ASTM E1269 |

||

| Plane thermal conductivity (x-y)/(W/m · K) |

1100-1300 |

1200-1400 |

1300-1500 |

1400-1600 |

1300-1500 |

1400-1600 |

1500-1700 |

ASTM E1461 |

||

| Density (g/cm3) |

1.4-1.8 |

1.9-2.1 |

1.9-2.1 |

1.9-2.1 |

1.9-2.2 |

1.9-2.2 |

1.9-2.2 |

YBSpec |

||

| Temperature resistance/℃ |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

TG-DSC |

||

| Durability on bending times |

>20000 |

>20000 |

>20000 |

>20000 |

>20000 |

>20000 |

>20000 |

YB Spec |

||

| Tensile strength/MPa |

>25 |

>25 |

>25 |

>25 |

>25 |

>25 |

>25 |

ASTM F152 |

||

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2