Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

1、 Introduction to FPC PI Copper Plating

1.FPCPI Copper PlatingDefinition of

Flexible Printed Circuit (FPC) is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film as the substrate. It has the characteristics of high wiring density, light weight, thin thickness, and good bendability.

2. Characteristics of FPC

1) Short: Short assembly time

All lines have been configured Eliminate the need for extra wiring connections

2) Small: smaller in size than PCB

It can effectively reduce the volume of the product Increase convenience in carrying

3) Lightweight: lighter in weight than PCB (hard board)

Can reduce the weight of the final product

4) Thin: thinner than PCB

Can improve softness Strengthen the assembly of three-dimensional space within a more limited space

3. Structure and Materials of FPC

In the structure of flexible circuits, the materials used are insulating films, adhesives, and conductors.

According to the number of layers of conductive copper foil, it can be divided into single-layer board, double-layer board, multi-layer board, double-sided board, etc. FPC with two or more layers is connected to each layer through conductive holes.

Soft board material classification: Base material (BASE): Protective film (CC): Adhesive (ADH): Reinforced CSTF; Shielding layer (SHIELD); PSA adhesive: solder mask ink, etc;

1) Base film: The material is generally polyimide (PI) or polyester (PET). The material thickness is 12.5, 25, 50, 75, and 125um. Commonly used are 12.5 and 25um. PI is superior to PET in various performance aspects.

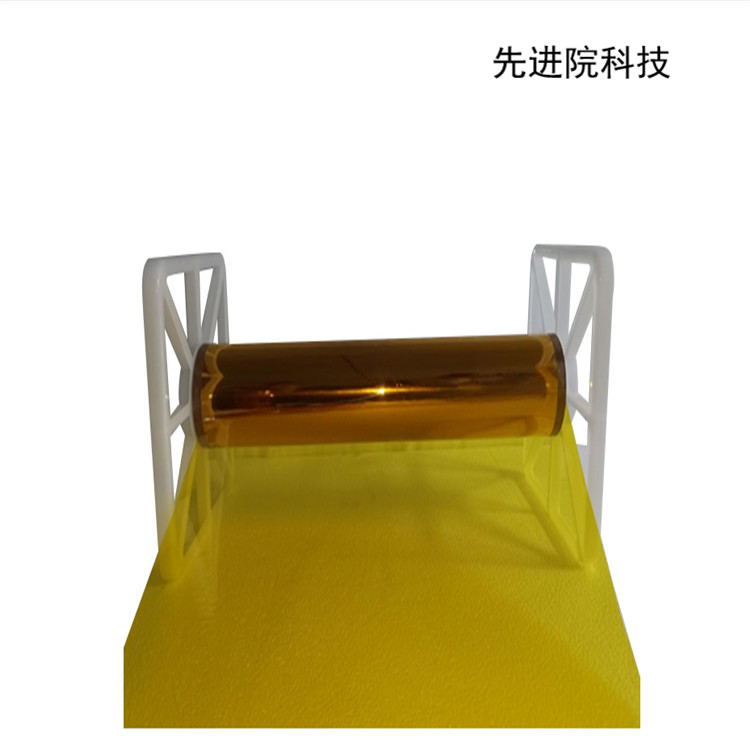

2) Copper foil layer (COPPER FOIL): There are two types: rolled copper (RA COPPER) and electrolytic copper (ED COPPER). The material thickness is 18, 35, and 75um. Due to the better mechanical properties of rolled copper compared to electrolytic copper, rolled copper is preferred in FPCs that require frequent bending. The copper foil thickness of the main screen FPC is generally 18um; For hollow FPC boards (such as those with window type interfaces), 35um should be used.

3) COVER LAYER: The material is the same as the base layer, covering the copper foil to provide insulation, solder mask, and protection. The commonly used material thickness is 12.5um.

4) ADHESIVE: It has a bonding effect on each layer.

5) Stiffener and Reinforcement Film: For plug-in FPC, in order to match with standard sockets, a reinforcement plate needs to be added on the back of the contact surface, which can be made of PI, PET, and FR4 materials; Commonly used PET. The thickness of the contact position after the reinforcement plate is attached depends on the requirements of the socket, generally 0.3, 0.2, or 0.12mm. For the FPC end that needs to be bonded to the LCD, a reinforcing film should be designed on the back of the contact surface, using 12.5um PI material.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2