Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

At present, the mobile phone film on the market can generally be divided into two categories: PET based plastic film and tempered glass film, and the structures of these two films have significant differences. Let's first take a look at the structure of plastic film for mobile phones.

With the popularity of smartphones, users have increasingly high requirements for mobile phone protective films, especially in terms of the light and shadow effects of protective films. Because of this, ordinary mobile phone protective films on the market can no longer meet your high-quality needs. In this case, Advanced Institute Technology recommends optical grade mobile phone PET protective films.

Although optical grade PET protective film for mobile phones has achieved hot sales in some places, it is still only used by a small number of high-end users in China. A large part of the reason is that domestic consumers are not familiar with optical grade mobile phone film materials. What is the difference between this optical grade PET protective film for mobile phones and ordinary mobile phone film materials on the market?

The use of ordinary mobile phone PET protective film is mainly to protect the phone from damage, so the focus is often on its anti scratch, light transmittance, anti fingerprint and other functions. Most of the mobile phone film materials currently sold on the market, such as high transparency scratch resistant, frosted anti fingerprint, mirror AR、 Most anti peeping functional films belong to this category. But they do not have high requirements for the light and shadow effects of the film, as well as touch sensitivity.

But the PET protective film for optical grade mobile phones is different. It is developed on the basis of ordinary mobile phone film materials, and in addition to having all the basic functions of ordinary mobile phone film materials, it pays more attention to the optical properties of the film. So this protective film has ultra-high light transmittance, and its color reproduction is extremely strong, which can also maintain the original display effect of the phone screen after use.

Compared with ordinary film materials, optical grade PET protective film for mobile phones has stronger anti glare properties, anti reflection effect, anti ultraviolet effect, and high touch sensitivity, bringing better touch audio and video experience to mobile phone users.

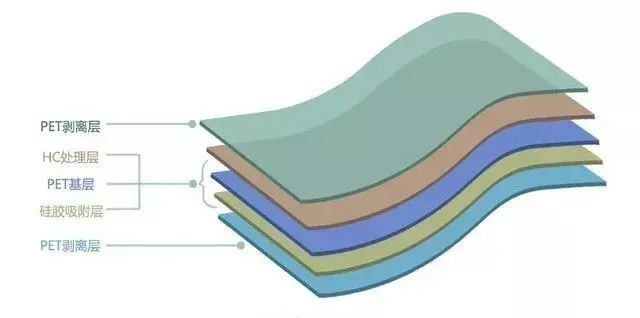

The structure of mobile phone plastic film is generally three layers of PET protective film: one layer of release film, one layer of PET protective film, and one layer of release film. Only the middle PET protective film is to be attached to the mobile phone screen, and the outer release film is to prevent the PET film from getting dirty and protect the PET film. The double-layer PET film has one less release film.

Tempered glass film generally consists of 4 layers, with the first layer being a special coating; The second layer is tempered glass; The third layer is explosion-proof film; The fourth layer is a silicone coating.

Whether it's plastic film or tempered glass film, the innermost layer is a silicone coating, which is the key to how the film adheres to the screen. The advantage of tempered glass film is its strong automatic adsorption and exhaust bubble function, making it easy for even beginners who have never applied mobile phone film to do so.

Transparency, wear resistance, adsorption, and edge cutting process are the four main quality indicators of screen protectors. Among them, the wear resistance and adsorption of screen protectors are the two main factors affecting their service life. Wear, curling, and bubbling are the main reasons for users to replace screen protectors.

Since wear resistance and adhesion affect the service life of screen protectors, how does the film adhere to the phone screen? There are mainly two types of adhesion methods for mobile phone film nowadays: non electrostatic adsorption and electrostatic adsorption. Non electrostatic adsorption mainly refers to adhesive bonding, although the bonding is relatively firm, it is also prone to various problems. Firstly, there are traces of adhesive residue, and secondly, after the film has been applied for a long time and then peeled off, the screen may feel insensitive to touch due to the infiltration of adhesive.

Relatively speaking, electrostatic adsorption film will not produce the above phenomenon. The adsorption method of static electricity is based on the principles of physics. When the protective film comes into contact with the liquid crystal screen, the pressure in the air between the protective film and the liquid crystal screen decreases, making the atmospheric pressure greater than the pressure of the air between the screen and the film, thereby generating adsorption capacity. Electrostatic film is not only easy to stick, but also relatively easy to tear off.

When purchasing screen protectors, in addition to considering the scratch resistance of the film, attention should also be paid to its adsorption properties. It is not just about electrostatic adsorption. The electrostatic adsorption screen protectors sold on the market are more accurately described as electrostatic silica gel ion adsorption. The adsorption capacity of the silica gel layer has a great impact on the adsorption performance of the film. Different manufacturers' electrostatic adsorption screen protectors also have significant differences in the adsorption capacity of the silicone layer due to their different technical levels. Therefore, although they are all electrostatic adsorption screen protectors, the service life of different brands of screen protectors varies due to differences in adsorption properties.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2