Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

| Basic and special requirements for adhesives |

|

| basic function |

Basic Requirements |

| As a medium for bonding electrode active materials, conductive agents, and electrode current collectors |

Good dispersibility in the slurry medium is beneficial for uniformly bonding the active substance to the current collector; |

| Special environmental factors |

Other special requirements |

| The adhesive and electrode material are immersed in the electrolyte for a long time together |

Does not swell or has a low swelling coefficient in the electrolyte |

| Long term exposure to high potential (positive electrode binder) or low potential (negative electrode binder) conditions |

Chemical stability and electrochemical stability are good, as they do not react or deteriorate during storage and cycling processes |

| Volume change of electrode active material during lithium insertion and extraction process |

Adhesive energy consumption and high tensile strength; |

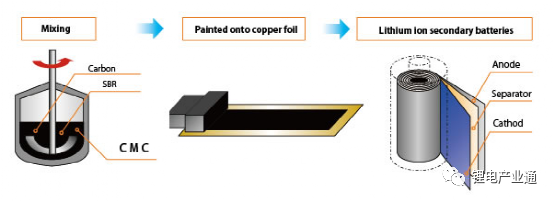

Early negative electrode binders used oil-based binders, such as the popular material PVDF. However, using oil-based binders resulted in severe internal polarization in batteries. Compared to water-based materials, water-based binders do not have this drawback and have a bonding effect that is safe, environmentally friendly, and cost-effective. Therefore, nowadays, water-based binders are mostly chosen as negative electrode binders. Commonly used water-based binders include carboxymethyl cellulose sodium (CMC), styrene butadiene rubber (SBR), polyacrylic acid (PAA), LA132/LA133, etc.

Next, let's take a look at well-known companies that specialize in binders for lithium-ion battery negative electrode materials.

A Japanese paper company has established manufacturing equipment for carboxymethyl cellulose (CMC) with an investment of approximately 4.7 billion yen, increasing the production capacity for advanced uses of CMC by three times. The equipment was completed and put into use in November 2020.

“Sunrose ®” It is the product name of CMC (carboxymethyl cellulose) made in Japan.

CMC is an anionic water-soluble polymer obtained from cellulose as raw material. Has excellent viscosity, water absorption, and water retention. In addition, due to its origin from natural cellulose, it has moderate biodegradability and can be incinerated after use, making it an extremely environmentally friendly material. In recent years, with the popularization trend of electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs), the demand for CMC in lithium-ion batteries (LiBs) has also increased.

Image source: Japanese made paper

Website: https://www.nipponpapergroup.com/

Norion is a global leader in specialty chemicals. Various industries around the world rely on their essential solutions to produce daily necessities such as personal care products, cleaning supplies, coatings, building materials, agricultural products, food, and pharmaceuticals.

Image source: Norion

Norion acquires J.M. Huber Corporation's carboxymethyl cellulose (CMC) business to continue its accelerated growth plan, which will greatly expand Norion's CMC product portfolio. CMC is a sustainable bio based water-soluble polymer that can be used as a thickener, binder, stabilizer, and film-forming aid.

Norion's CMC business has acquired a factory in Finland. The acquired business unit produces a complete range of CMC products and provides services to customers in over 80 countries and regions, including China.

Website: https://www.nouryon.com/zh-cn/

Daicel is a Japanese chemical company. In 1966, it was renamed as Da Sai Lu Company. The first subsidiary, Fujifilm, was established in 1934, mainly producing nitrocellulose films. The main products of one of the manufacturing bases, Himeji Manufacturing Plant - Wanggan Factory, are cellulose acetate/acetate fiber bundle/CMC/HEC/acetic acid/mercaptoacetic acid.

Image source: Da Sai Lu from Japan

The CMC Daicel series is mainly determined by the viscosity and degree of substitution of a 1% aqueous solution, which represents the strength of the CMC structure. Da Sai Lu Company offers various grades ranging from extremely high viscosity to low viscosity. The most popular lithium-ion battery grade is "CMC DAICEL 2200".

| type |

Degree of substitution |

grade |

*Viscosity (mPa · s) |

| Common |

0.6~0.8 |

1110 |

100-200 (2%) |

| 1120 |

20-50 |

||

| 1130 |

50-100 |

||

| 1140 |

100~200 |

||

| 1150 |

200-300 |

||

| 1160 |

300~500 |

||

| 1170 |

500~800 |

||

| 1180 |

1000~1300 |

||

| 1190 |

1300~2000 |

||

| Acid and salt resistant type |

0.8~1.0 |

1220 |

10-20 |

| 1240 |

30-40 |

||

| 1250 |

40-70 |

||

| 1260 |

80~150 |

||

| 1.0~1.5 |

1330 |

50-100 |

|

| 1350 |

200-300 |

||

| 1380 |

1000~ |

||

| 1390 |

2500~4500 |

||

| High viscosity type |

0.8~1.0 |

2200 |

1500~2500 |

| 0.8~1.0 |

2260 |

4000~6000 |

|

| 0.7~0.85 |

2280 |

8000~ |

Image source: Da Sai Lu from Japan

Website: https://www.daicel.com/

Xinxiang Jinbang Power Technology Co., Ltd. (Shenzhen Jinbang Power Technology Co., Ltd.) was established in 1998. The company integrates research and development, production, and marketing, and has a research and management team. As a major professional supplier of lithium battery grade CMC in China.

The CMC performance of Jinbang Power Supply in Xinxiang City is as follows:

1. It can solve the problem of battery pole cracking, and CMC pole has better flexibility, which can effectively solve the cracking problem.

2. CMC can reduce the surface defects of battery electrodes, strictly control solid insoluble substances, and solve the electrode defects caused by CMC.

CMC can enhance the capacity, cycling stability, and lifespan of lithium batteries.

4. It can increase the voltage platform of the battery, reduce the internal resistance of the battery, and lower the internal pressure of the battery to improve its high current operation characteristics.

5. CMC with stable molecular weight can provide stable viscosity and adhesion, facilitating production control.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2