Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Every discovery and application of new materials will bring tremendous progress to human civilization. From the Stone Age, Bronze Age, and Iron Age to the Silicon Age and Carbon Age, new materials have made increasingly significant changes to our lives. And now, a wave of new materials has emerged, which will build a better future for our lives.

1Scientists have developed a new type of outer protective material for spacecraft

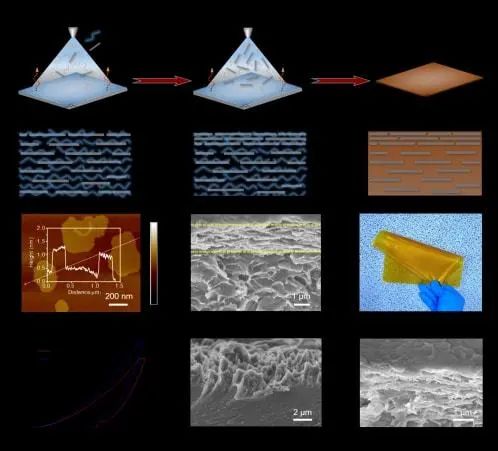

According to a report from China Science Daily on December 1st, a team led by Academician Yu Shuhong from the University of Science and Technology of China has developed a new type of outer protective material for spacecraft - polyimide nano mica composite film. This new material, due to its unique biomimetic design, has significantly improved its mechanical properties and tolerance to extreme spatial environments, and is expected to replace existing polyimide based composite film materials. This achievement was recently published in Advanced Materials.

Image source: China Science Journal

Polyimide film has become an excellent material for space probe "protective clothing" due to its excellent mechanical properties, excellent thermal stability, and outstanding chemical resistance. However, like other hydrocarbon polymers, this material is highly susceptible to atomic oxygen attacks in the space environment, leading to a sharp decline in its physical and mechanical properties, and there is currently no good solution. In addition, cosmic ray radiation and space debris impacts also pose severe challenges to its stability.

Academician Yu Shuhong's team was inspired by the "brick mud" layered structure of natural mother of pearl and utilized the superior intrinsic properties of mica to compensate for the shortcomings of polyimide. This design strategy not only effectively improves the mechanical properties of materials, but also enhances their surface resistance to atomic oxygen, ultraviolet radiation, and space debris.

Research has shown that the tensile strength, Young's modulus, and surface hardness of this new biomimetic composite film are 125 megapascals, 2.2 gigapascals, and 0.37 gigapascals, respectively, which are 45%, 100%, and 68% higher than pure polyimide film, respectively. Due to the unique double-layer structure of mother of pearl and the inherent performance advantages of mica nanosheets, the double-layer polyimide nano mica composite film exhibits superior atomic oxygen resistance, significantly better than pure polyimide films, single-layer mother of pearl structure polyimide mica composite films, and previously reported polyimide based composite materials. In addition, its resistance to UV aging and high-temperature stability have also been significantly improved.

Industry insiders believe that the unique double-layer imitation mother of pearl structure design strategy proposed in this study provides new ideas for designing and constructing other high-performance nanocomposites.

2MIT team finds new 'semi-solid' flow battery material

In order to build an affordable grid energy storage solution, flow battery devices have once again attracted widespread attention from researchers in recent years.

The MIT research team has developed a new electrode material similar to soft ice cream, which they believe can be integrated into "semi-solid" batteries to store renewable energy in a cheaper way.

Image source: Thaneer Narayanan/MIT News

In terms of renewable energy storage, flow batteries are a highly attractive research direction. Compared with lithium-ion batteries, they have advantages such as flexibility, scalability, and low cost. Even better, flow batteries can store energy for several months to fill the peak valley gap of solar and wind energy. And the new plan of the MIT research team has further maximized the cost.

The research author Thaneer MalaiNarayanan stated, "We conducted a comprehensive and top-down analysis, considering various trade-offs, to understand how much the composition of the battery affects performance and cost. The results showed that our system is cheaper than other control groups and can be flexibly scaled up.

3New polymer combines silica sand into composite material

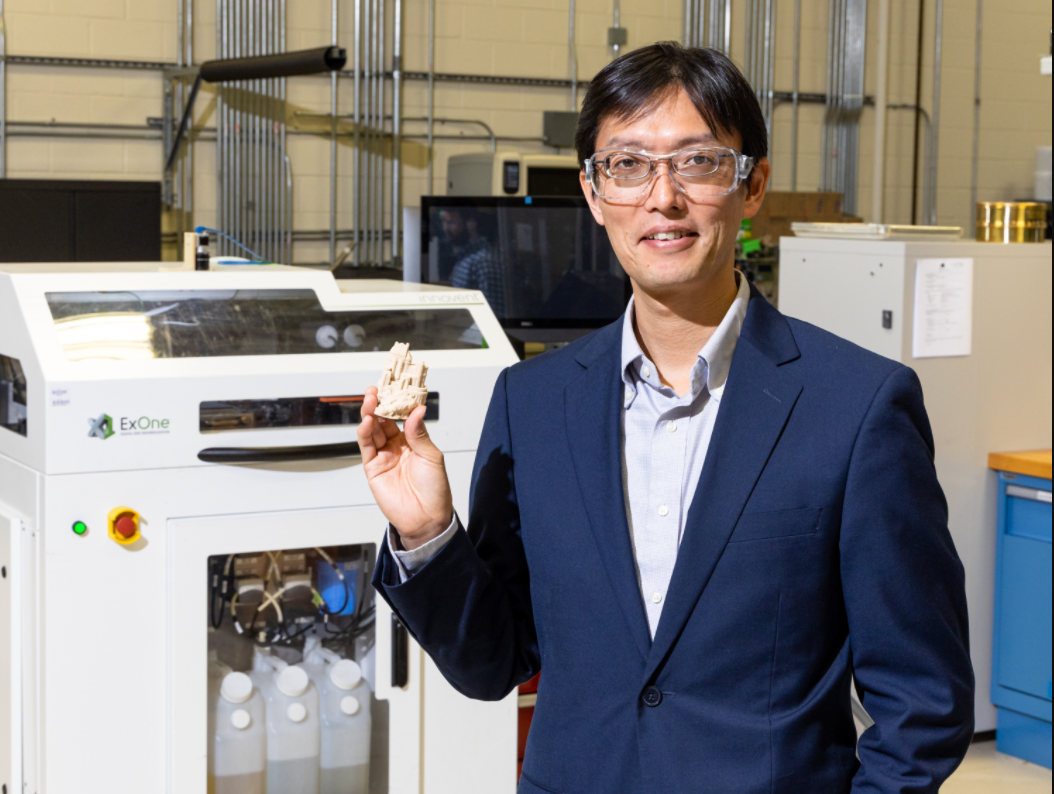

Researchers from Oak Ridge National Laboratory (ORNL) have designed a novel polymer to bond and enhance silica sand for adhesive jet additive manufacturing. This is a 3D printing method used in industry for prototyping and production of components.

The ORNL team has created a polyethyleneimine (PEI) adhesive that can double the strength of sand components compared to traditional adhesives.

Image source: ORNL

The parts printed by adhesive jet are initially porous when removed from the printing bed. Through infiltration design, an additional strong adhesive material called cyanoacrylate can be added to fill gaps and improve strength. On the basis of the first step, the strength of the second step increased by 8 times, making the polymer sand composite material stronger than any other known building material, including bricks and stones.

The chief researcher of the project, Tomonori Saito, said, "Very few polymers are suitable for use as adhesives in such applications. Researchers have been searching for special properties that can achieve the best results, such as solubility. The key finding is that PEI adhesives have a unique molecular structure that can react with cyanoacrylate salts to achieve excellent strength

One of the potential applications of ultra-high strength sand is in advanced composite material manufacturing molds. Silica sand is an easily obtainable low-cost material that is increasingly popular in the automotive and aerospace industries, and can be used to manufacture composite components. For example, using 3D printed sand cores or "molds" to wrap lightweight materials such as carbon fiber or glass fiber, and then heating and curing. Silicon sand is more suitable for use as a mold because it does not change size when heated and has unique advantages in washable molds. In the application of composite materials, the use of water-soluble adhesives to construct sand molds is of great significance, as it can be easily removed by flushing with tap water, leaving behind a hollow composite material form. Lead researcher Dustin Gilmer said, "In order to ensure the accuracy of mold components, a material that does not change shape during processing is needed, so silica sand is highly regarded. The challenge is to overcome the structural weaknesses of sand parts

4NTNU has developed a new type of spider silk elastic material

Image source: Forward looking website

Inspired by the super strong spider silk, researchers at the New Zealand University of Technology have developed a new material that overcomes the trade-off between toughness and stiffness.

The new material is a polymer called elastomer, which has the elasticity of rubber. The characteristic of this newly developed highly elastic polymer is that the molecule has eight hydrogen bonds in a repeating unit, which helps to evenly distribute the stress applied to the material, making it so durable.

These eight hydrogen bonds are the origin of this extraordinary mechanical property, "said Zhiliang Zhang, a professor of mechanics and materials at the Department of Structural Engineering at NTNU

Scientists have previously noticed that spider silk - especially the dragline that provides spider web spokes and edges - is exceptionally hard and tough. Stiffness and toughness are completely different properties in engineering, often opposing each other. Hard materials can withstand significant pressure before deformation, while hard materials can absorb a large amount of energy before fracture. For example, although glass is hard, it is not hard.

In addition to its mechanical properties, this material is also transparent, and studies have shown that it can even achieve self-healing at temperatures above 80 ° C. If production can be expanded, this new material may one day be used in flexible electronic products, especially wearable devices that are prone to damage and breakage.

In addition, researchers also hope to expand the performance of this material to have anti icing (preventing ice from sticking to it at low temperatures) and anti pollution (preventing aquatic organisms such as mussels and algae from adhering to it) properties, so that it can be used in extreme conditions, such as the Arctic.

5Wood waste can be used as a renewable/recyclable alternative to thermosetting plastics

Most thermosetting resins are not only made from non renewable components, but also difficult to recycle. Swedish scientists have started to address these issues and developed a new lignin based thermosetting material that can be reused multiple times.

Lignin is an organic polymer that constitutes most of the supporting tissues of plants, including trees. It is also a byproduct of the pulp and paper industry, which has been proposed for use in fields such as cheaper batteries, discarded carbon fiber, and stronger concrete.

Image source: Online

Researchers at Stockholm University have combined lignin with a non-toxic crosslinking chemical extracted from ethylene glycol to create a material with properties similar to traditional thermosetting resins. This material does not require prior chemical changes to lignin, and can be "boiled" together with crosslinking agents to form various shapes through traditional casting or injection molding techniques. It can be said to be very simple and environmentally friendly to use.

Researchers can adjust the properties of the material by changing the ratio of lignin to crosslinking agent - it can be soft and tough, or hard and brittle. In addition, it can be thermally decomposed and reused multiple times while maintaining good mechanical strength, which is said to be comparable to existing engineering plastics.

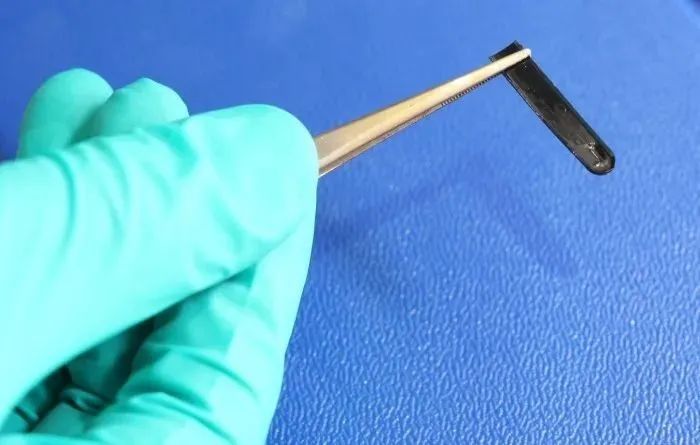

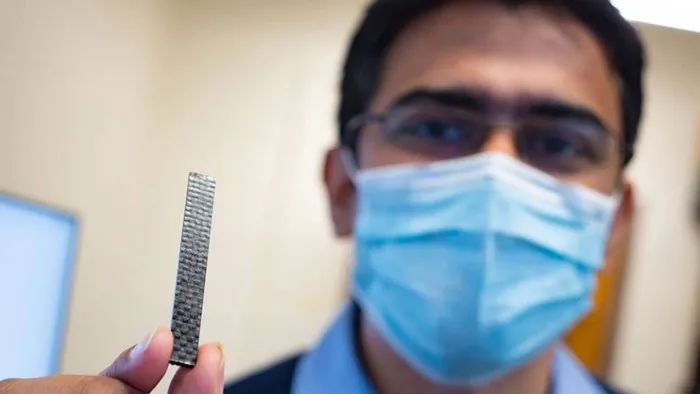

6New carbon fiber composite materials can utilize thermal energy for healing

Professor Aniruddh Vashisth from the University of Washington has developed a new, highly robust, and lightweight carbon fiber composite material. For current carbon fiber materials, once damaged, it is basically impossible to repair or recycle. And this new carbon fiber composite material is different from traditional carbon fiber, it can be repeatedly repaired.

Image source: cnBeta.COM

The new carbon fiber composite material is as strong as traditional carbon fiber, but has the advantage of being able to be repeatedly repaired using heat, which can reverse any fatigue damage to the material. When the material needs to be recycled, it can also be used to decompose.

Developing a material that can be recycled or repaired using traditional heat sources or radio frequency heating is a key discovery, as traditional carbon fibers cannot be recycled.

The best time to change the future is now. I believe that with the development of technology, more and more unexpected new materials will appear in our lives, helping humanity build a better tomorrow.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2