Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

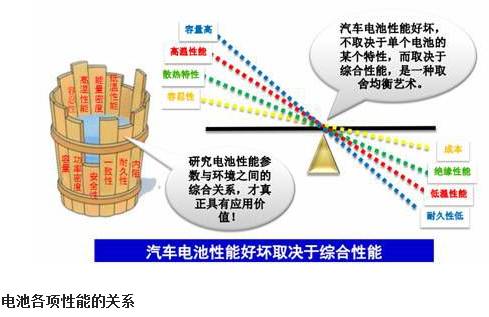

Secondly, the thermal related issues of lithium-ion batteries directly affect their safety. Defects in the production and manufacturing process or improper operation during use may cause local overheating of the battery, leading to a chain reaction of heat release and ultimately causing serious thermal runaway events such as smoking, fire, and even explosion, posing a threat to the safety of vehicle drivers and passengers.

In addition, the working or storage temperature of lithium-ion batteries affects their service life. The suitable temperature for batteries is between 10-30 ° C, and temperatures that are too high or too low will cause a rapid decline in battery life. The large-scale development of power batteries has led to a relative reduction in the ratio of surface area to volume, making it difficult for the internal heat of the battery to dissipate. This may result in uneven internal temperature and excessive local temperature rise, further accelerating battery degradation, shortening battery life, and increasing the total cost of ownership for users.

The battery thermal management system is one of the key technologies to address the thermal related issues of batteries and ensure the performance, safety, and lifespan of power batteries.

The main functions of a thermal management system include:

1) Effectively dissipate heat when the battery temperature is high to prevent thermal runaway accidents;

2) Preheat the battery when the temperature is low, increase the battery temperature, and ensure charging and discharging performance and safety at low temperatures;

3) Reduce temperature differences within the battery pack, suppress the formation of local hot zones, prevent rapid degradation of batteries at high temperature locations, and reduce the overall lifespan of the battery pack.

■ ■■■■

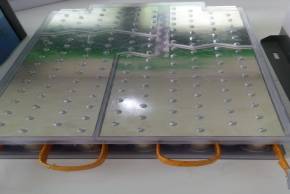

The function of thermal conductive silicone gasket

The function of thermal conductive silicone film filled with materials with good electrical insulation or thermal conductivity between batteries and between batteries and pipelines is to:

1) Change the contact form between the battery and the heat dissipation pipeline from line contact to surface contact;

2) Beneficial for improving the temperature uniformity between individual cells by one degree;

3) Beneficial for improving the overall heat capacity of the battery pack, thereby reducing the overall average temperature.

Heat dissipation principle of battery thermal management system

Advanced Institute Technology thermal solutions from thermal conductive silicone sheet manufacturers ensure more stable performance of your car batteries, extend the lifespan of your battery pack, and maximize its performance.

■ ■■■■

Heat dissipation principle of automotive battery thermal management system

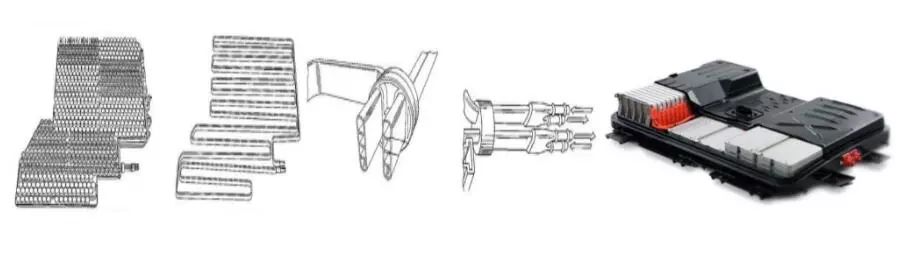

1、 Heat dissipation principle:

Heat dissipation principle: Due to the temperature difference inside the battery pack not being controlled within 5 ℃, a heat dissipation silicone sheet is attached to both the top and bottom of the battery pack. The silicone sheet then guides the temperature to the outer aluminum shell, and the temperature difference of the entire battery module is controlled within 5 ℃, meeting the requirements of the battery pack design, making the battery pack have a longer lifespan and more stable performance during driving.

Heat dissipation principle: Utilizing a fan to actively dissipate heat, with the fan supplying air that blows towards the battery channel, removing heat from the inside of the battery pack.

2、 Heat dissipation principle:

The battery pack adopts passive heat dissipation by attaching a thermal conductive silicone sheet between the battery pack and the aluminum heat dissipation plate. The silicone sheet transfers the temperature to the aluminum plate, which then exchanges heat with the air.

3、 Heat dissipation principle:

The battery pack adopts passive heat dissipation by attaching a thermal conductive silicone sheet between the battery pack and the aluminum heat sink. The silicone sheet transfers the temperature to the aluminum heat sink, which then exchanges heat with the air

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2