Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

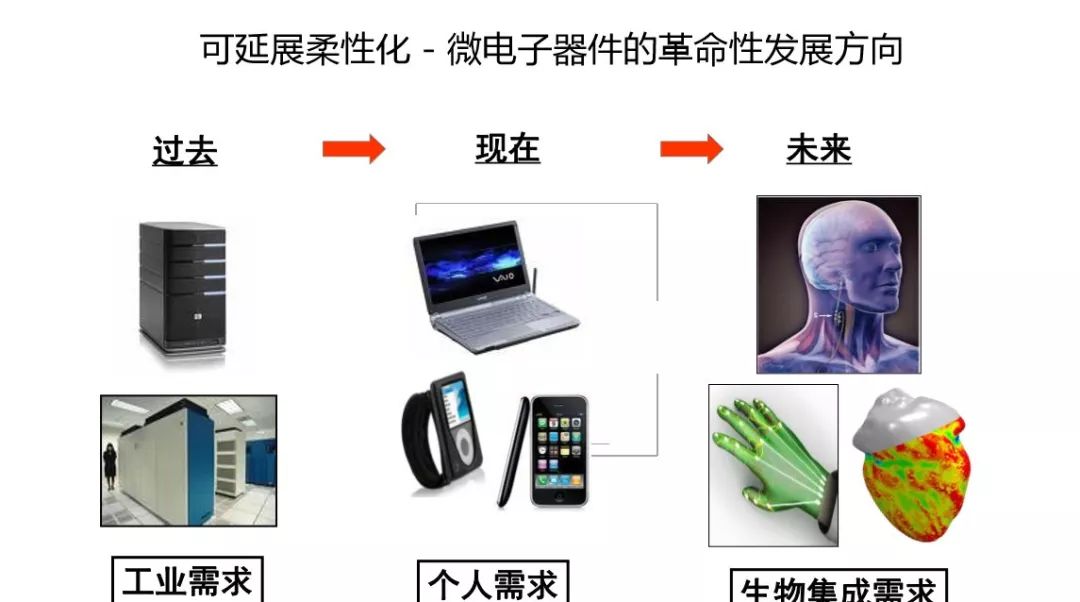

The strategic layout of flexible electronic projects in countries such as the United States, Japan, and South Korea will maintain a high-speed growth trend in the high-precision field for a long time.

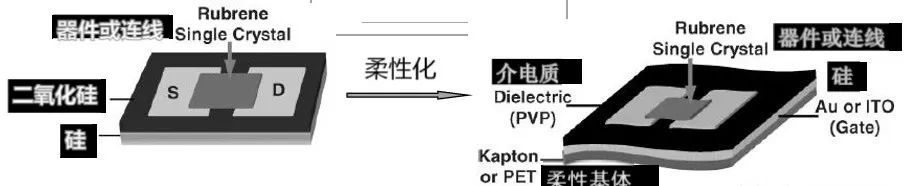

Flexible electronics is the technology of attaching inorganic/organic devices to flexible substrates to form circuits. Compared to traditional silicon electronics, flexible electronics refer to thin film electronic devices that can be bent, folded, twisted, compressed, stretched, or even transformed into any shape while maintaining high efficiency, reliability, and integration.

The United States, Japan, South Korea, and other countries have strategically laid out flexible electronics projects, which will maintain a high-speed growth trend in the high-precision field for a long time. This is also a historical opportunity that China should seize as much as possible.

Common materials for flexible electronics

1flexible substrate

In order to meet the requirements of flexible electronic devices, properties such as thinness, transparency, good flexibility and stretchability, insulation and corrosion resistance have become key indicators of flexible substrates.

Common flexible materials include polyvinyl alcohol (PVA), polyester (PET), polyimide (PI), polyethylene naphthalate (PEN), paper, textile materials, etc.

Polyanilide materials have the advantages of high temperature resistance, low temperature resistance, chemical resistance, and good electrical properties, making them the most promising materials for flexible electronics. However, in the selection of flexible substrates, in addition to considering high temperature resistance, factors such as light transmittance, surface roughness, and material cost must also be taken into account.

Polydimethylsiloxane (PDMS) is also widely recognized as a flexible material, with advantages including easy availability, stable chemical properties, transparency, and good thermal stability. The distinct characteristics of adhesive and non adhesive areas under ultraviolet light make it easy for electronic materials to adhere to its surface.

Although PET has a low conversion temperature of about 70-80 ℃, its low price and excellent light penetration make it a cost-effective material for transparent conductive films.

2Metallic materials

Metal materials are generally conductor materials such as gold, silver, and copper, mainly used for electrodes and wires. For modern printing technology, conductive materials often use conductive nanoinks, including nanoparticles and nanowires. Metal nanoparticles not only have good conductivity, but can also be sintered into thin films or wires.

3Organic materials

Large scale pressure sensor arrays are crucial for the development of future wearable sensors. Pressure sensors based on piezoresistive and capacitive signal mechanisms suffer from signal crosstalk, leading to inaccurate measurements, which has become one of the biggest challenges in the development of wearable sensors.

Due to the perfect signal conversion and amplification performance of transistors, their use provides the possibility to reduce signal crosstalk. Therefore, many studies in the fields of wearable sensors and artificial intelligence are focused on how to obtain large-scale flexible pressure-sensitive transistors.

Traditionally, p-type polymer materials used for field-effect transistor research are mainly thiophene based polymers, with the most successful example being the poly (3-hexylthiophene) (P3HT) system. Naphthalene tetraacyl diamine and perylene tetraacyl diamine exhibit excellent n-type field-effect properties and are the most widely studied n-type semiconductor materials, widely used in small molecule n-type field-effect transistors.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2