Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

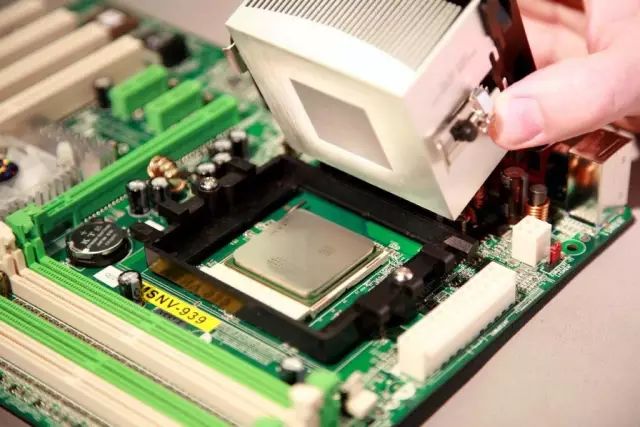

Polymer thermal conductive materialThere are many mature design schemes for heat dissipation in larger space electronic devices, which will not be elaborated here. With the rapid development of microelectronics technology, the size of chips is getting smaller and the computing speed is getting faster, resulting in increasing heat generation. For example, the maximum heat generated by the Intel processor 3.6G Pentium 4 Ultimate Edition during operation can reach 115W, which puts higher demands on the heat dissipation of chips. Designers must use advanced heat dissipation technology and high-performance heat dissipation materials to effectively remove heat and ensure that the chip operates normally within the maximum temperature it can withstand. The appearance of electronic devices and terminals is increasingly demanding a thinner and smaller design. TVs have evolved from CRT to LCD flat panel TVs, desktop computers to laptops, as well as digital set-top boxes, portable CDs, etc. The heat dissipation design is different from traditional forms because these products are relatively thinner and smaller.

Statistical data shows that for every 2 degrees increase in temperature of electronic components, reliability decreases by 10%; The lifespan at a temperature rise of 50 degrees is only 1/6 of that at a temperature rise of 25 degrees. Temperature is the most important factor affecting equipment reliability. This requires taking technical measures to control the temperature rise of the chassis and components, which is known as thermal design. The principles of thermal design are twofold: firstly, to reduce heat generation by using better control methods and technologies, such as phase-shifting control technology, synchronous rectification technology, etc.; secondly, to select low-power devices, reduce the number of heat generating devices, increase the width of thick printed lines, and improve the efficiency of the power supply. The second is to strengthen heat dissipation, which means using conduction, radiation, and convection technologies to transfer heat,

But for products made of flat thermal conductive polymer materials, firstly, in terms of space, more heat dissipation aluminum sheets and fans cannot be used. Overall, it is not allowed to strengthen the cold heat dissipation design and convection form cannot be used. The same radiation heat dissipation method is also difficult to achieve in flat spaces. So everyone spontaneously thought of using the chassis for heat dissipation, which has the advantage of not considering adding fan power due to the fan, not causing more dust due to the fan, and eliminating the noise caused by the fan.

How can we truly make good use of the heat dissipation of the machine casing? The opportunity for the application of polymer thermal conductive composite materials has arrived. Soft thermal conductive silicone insulation pad is a type of heat transfer interface material, which is a sheet-like material that can be cut according to the size and shape of the heating power device. It has good thermal conductivity and insulation properties, and its function is to fill the gap between the heating power device and the heat sink. It is the best product to replace thermal conductive silicone grease. The thermal conductivity of polymer materials is 1-12W/mK, while the thermal conductivity of air is 0.03W/mK; The anti voltage breakdown value is above 4000 volts and can be used in most electronic devices with insulation requirements The thickness of the process varies from 0.5mm to 12mm, with each 0.5mm being added in increments of 0.5mm, i.e. 0.5mm, 1mm, 1.5mm, and 2mm, all the way up to 12mm. The different thicknesses are designed to facilitate designers in selecting the position of the PCB board and heating power devices The flame retardant and fire-resistant properties meet the requirements of UL-94V0, and comply with the EU SGS environmental certification and RoHs certification. The working temperature is generally between -40 ℃ and 200 ℃, making it an excellent thermal conductive material And it is particularly soft, specially designed for the use of gaps to transfer heat. It can fill the gaps, complete the heat transfer between the heating and cooling parts, increase the thermal conductivity area, and also play a role in shock absorption, insulation, sealing, etc., which can meet the miniaturization of social equipment.

The requirement for ultra-thin design is a new material with high processability and usability And the thickness has a wide range of applications, especially suitable for electronic equipment industries such as automobiles, displays, computers, and power supplies.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2