Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

The future development direction of security products is that image processing capabilities will become increasingly high, and camera pixels will become more and more dense. From 720P to gradually moving towards high-end, high-definition pixels, 1080P, 4K image quality, etc. The demand for thermal interface materials will also increase to 6W-15W; Gradually developing towards cloud intelligence.

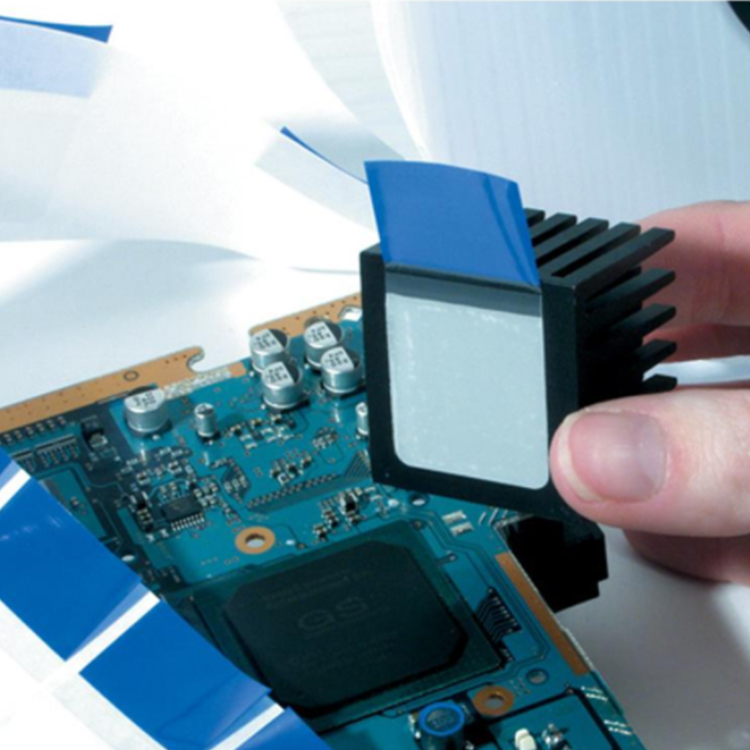

Principles of product heat dissipation design

1. Reduce heat generation

Choose better control methods and technologies, such as phase-shifting control technology, synchronous rectification technology, etc. In addition, choose low-power devices, reduce the number of heating devices, increase the width of thick printed lines, and improve the efficiency of the power supply.

2. Strengthen heat dissipation

Using conduction, radiation, and convection techniques to transfer heat, but for flat looking products, firstly, in terms of space, it is not allowed to use more aluminum fins and fans for heat dissipation. Overall, it is not allowed to strengthen the cold heat dissipation design and convection form cannot be used. The same radiation heat dissipation method is also difficult to achieve in flat spaces.

Six cooling methods for security cameras

1. Reduce the current. Using low-power infrared lamps instead of high-power ones, although reduces heat dissipation, the effect is definitely not as good as the latter when illuminating long distances.

2. Adding a cooling fan inside the array infrared gun shaped camera will definitely have some effect, but the test for the fan is very strict. Moreover, adding a fan is also a test for the design of the casing, ensuring both aesthetics and practicality.

3. Use a constant current power supply for power supply. Maintain a constant current and control the heat dissipation of the LED.

4. Grouping and arrangement of LED lights. For example, with 24 infrared rays, they can be arranged into 3 groups to reduce heat.

5. Selection of structural materials. For example, LED light boards and casings are made of materials with good heat dissipation, such as aluminum alloy.

6. The application of thermal conductive materials, using thermal conductive media materials to conduct the heat of the heating element to the shell and then dissipate it through natural convection, effectively solves this problem.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2