Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Reasons for chip shortage:

1. Short term factors; Due to the pandemic over the past year, the global semiconductor production capacity utilization rate was insufficient last year, and the inevitable natural disasters also exacerbated the shortage of chips, as follows:

① COVID-19 (COVID-19) has led to the decline in capacity utilization of the global semiconductor industry chain to varying degrees. In addition, natural disasters such as the snowstorm in the United States, the earthquake in Japan, and fires have also caused some semiconductor enterprises to shut down for a period of time, reducing the effective supply of chips;

② In order to speed up the expansion of mobile phone market share and increase the number of chips purchased, companies such as Xiaomi, OPPO and VIVO have placed large orders with chip manufacturers such as TSMC to occupy the share of small and medium-sized manufacturers;

③ During the epidemic, the public's demand for remote work and education has led to a surge in demand for computer and server related chips;

Capacity utilization rate chart of semiconductor component manufacturers in North America

2. Long term factors: The demand for chips in fields such as automobiles and mobile phones has significantly increased, and factors such as the development of the Internet of Things have led to a sustained and stable growth in global chip demand. However, production capacity manufacturers are cautious about expanding production, and there are certain capacity gaps in wafer manufacturing, packaging testing, silicon wafer production, and other links. The specific analysis is as follows:

① Entering the stage of automation, networking, and intelligence in automobiles is also a future development trend. The introduction of autonomous driving chips, IGBTs, and other technologies has significantly increased the value of a single automotive chip;

② Compared to before, 5G smartphones are more complex in terms of baseband chips, RF chips, and other aspects. The popularity of 5G smartphones has driven the growth of demand for chips in smartphones;

③ The cultivation of COVID-19, global remote work, and online education habits, driving the demand for servers, personal computers, etc., will continue to maintain high prosperity in the future;

④ In the early stage of 5G deployment, the growth in 5G base station shipments has driven an increase in demand for base station related chips;

Global Semiconductor Industry Scale and Downstream Map from 2005 to 2025

3. The semiconductor industry itself is in a new upward phase of the business cycle, with increased concentration of global wafer production capacity and limited expansion, making it difficult to meet the explosive demand. The analysis is as follows:

① After the 2008 financial crisis, the concentration of global wafer production capacity gradually increased, and the overall expansion speed of global wafer fabs slowed down;

② In recent years, the global expansion of production capacity has mainly been 12 inches, with less capacity for 8-inch wafers. However, due to factors such as chip yield and cost, some chips are still produced using 8-inch wafers, and fixed 8-inch production capacity is particularly scarce;

③ Global advanced production capacity can only be concentrated in a few wafer manufacturers. High end digital chips used in fields such as mobile phones/personal computers require advanced processes and are highly dependent on manufacturers such as TSMC and Samsung; About 70% of global automotive chips are manufactured by TSMC, especially in advanced processes, but automotive chips only account for about 3% of TSMC's production

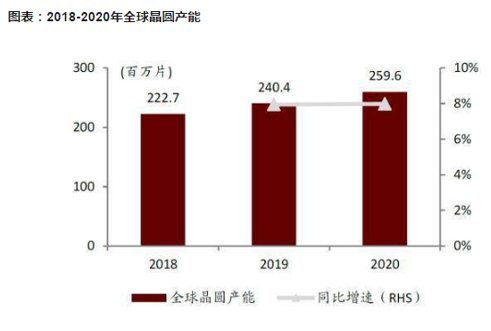

Global wafer production capacity map from 2018 to 2020

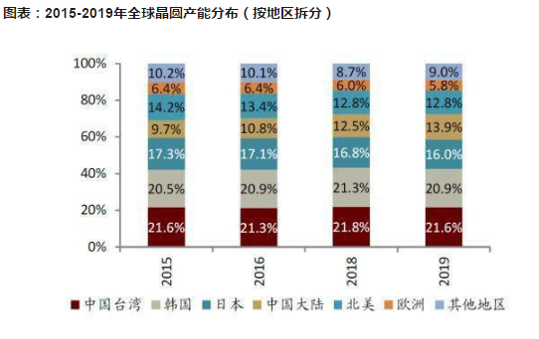

Global wafer production capacity distribution map from 2015 to 2019

Affected by the COVID-19, the supply chain has been tense. The Sino US trade conflict has disrupted the pace of the semiconductor industry chain, leading to a serious shortage of capacity. Even in the context of stock shortages, rising raw material prices, and new demands, Advanced Institute Technology Company actively takes response measures based on actual market demand, immediately "price locking" upstream and downstream supply, and signs phased procurement agreements with suppliers to lock in prices, in order to avoid upstream price fluctuations that may affect their production orders. Synchronize and integrate resources for centralized procurement. Centralized procurement is an effective measure to save procurement costs, which not only enhances the bargaining power of procurement, but also facilitates upstream enterprises to arrange orders and carry out large-scale production. Advanced Institute (Shenzhen) Technology Co., Ltd. is a high-tech enterprise that integrates independent research and development, production, and sales. With a 5-year focus on improving brand value, our products have good thermal conductivity, insulation, heat dissipation, and are non-toxic. Our products meet the 94V0 fire rating. It will not have any impact on the current market fluctuations for the time being

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2