Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Because lithium batteries can seriously affect their charging and discharging performance at low temperatures. The reaction during charging is the aggregation of lithium ions towards the negative electrode, where six carbon atoms capture one lithium ion. However, at low temperatures, lithium ions are prone to form lithium crystals on the negative electrode, known as "lithium precipitation". Lithium crystal deposition can puncture the separator, causing a short circuit inside the battery and ultimately damaging it. So a battery heating element is needed to heat the battery and ensure the normal charging and discharging of lithium batteries at low temperatures!

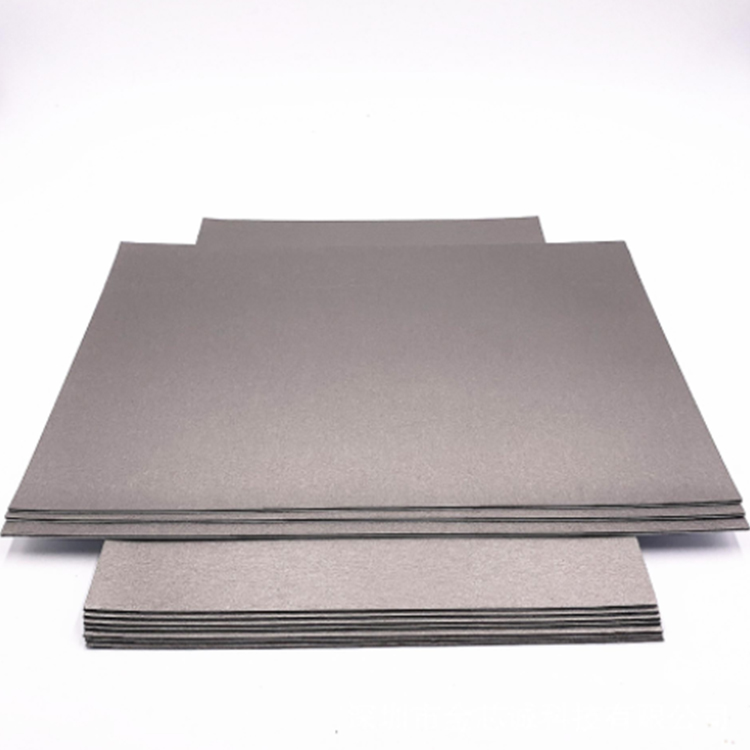

The heat of the battery cell is transferred to the outer shell through a thermal conductive silicone film. The outer shell is mostly made of metal material, which can directly lower the temperature of the battery cell and ensure the stability of the battery. (取决于上下文,如"but"Thermal conductive silicone sheetIt has good tear resistance, which can ensure the friction resistance and tear resistance of the battery during normal use in the car.

In order to meet the high torque requirements during the start-up and acceleration phases of electric vehicles, and to improve the efficiency of the electric motor, most electric buses need to be equipped with a transmission. The mechanical automatic transmission (AMT) adds an electronic control device to the original manual mechanical transmission, inheriting the inherent advantages of high transmission efficiency, compact mechanism, and reliable operation of gear transmission. It can also achieve manual and automatic mode selection, with strong reliability and adaptability, low cost, high efficiency, small size, and easy installation. It is composed of an electric motor, and the power transmission system can better exert the performance of electric buses.

The shifting actuator of AMT is divided into three forms: electrically controlled pneumatic, electrically controlled hydraulic, and electrically controlled electric. Among them, the electronic control electric shift actuator, which is driven by a small DC motor for shifting, has a relatively simple structure, light weight, easy control, high accuracy, and less error in the system's action. It is currently the most commonly used method. AMT operates stably and has excellent performance under low temperature conditions in spring and autumn, as well as non harsh high temperature conditions in summer. However, in extremely high temperature weather in summer, it is prone to malfunctions caused by overheating protection of the shifting motor, resulting in failure to shift gears smoothly and cause breakdowns. The reason is that the AMT transmission is close to heat sources such as the drive motor and engine, and natural air cooling does not have sufficient heat dissipation capacity, resulting in overheating protection failure at high temperatures.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2