Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Wireless charging uses a metal base for heat dissipation. There are many coils disassembled, and the middle part is the concentrated heat source. There is a silicone cap next to it. Wireless charging, also known as induction charging or non-contact induction charging, originates from wireless power transmission technology. It utilizes near-field induction, also known as inductive coupling, to transfer energy from a power supply device (charger) to a device that uses the received energy to charge the battery and supply it for its own operation.

Operation method 1

By prying open the gap along the edge of the wireless charger with a pry, you can see the internal coil, including the middle where the heat is most concentrated. So a temperature sensor is installed in the middle of the coil to ensure that the charger operates within a safe temperature range.

Operation method 2

By removing the screws on the metal substrate of the coil, the internal structure of the bottom shell of the product can be seen. The bottom shell is made of metal integrated molding, which is also the key to heat dissipation. The use of metal is to better transfer the heat inside the product to the outside through the bottom shell, so that the internal working temperature can always be maintained in a safe state, thereby delaying the service life of the product.

1

Product characteristics

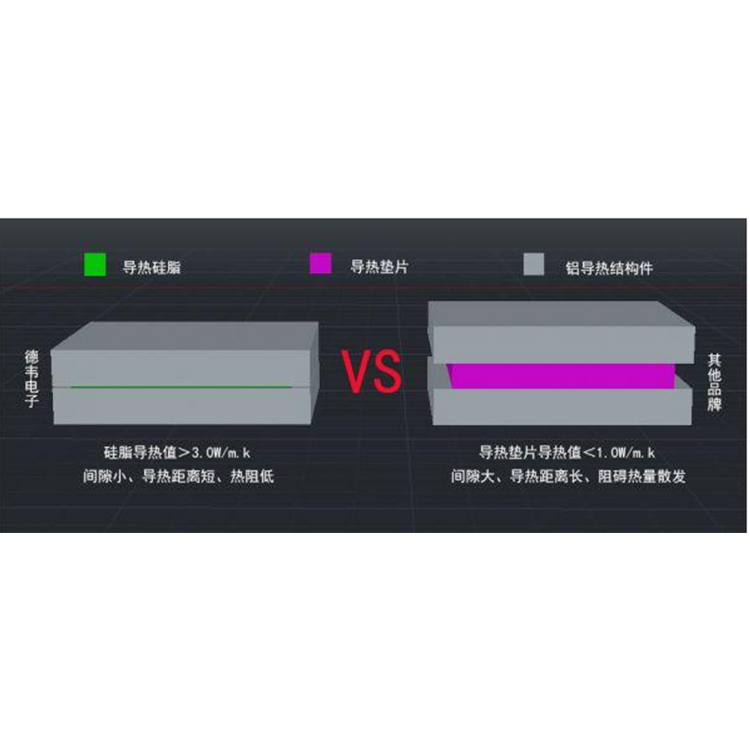

》Good thermal conductivity: 3.2W/mK

》Self adhesive without the need for additional surface adhesive

》Highly compressible, soft and elastic, suitable for low-pressure application environments

》Multiple thickness options available

2

Product Application

》Bottom or frame of radiator

》Set top box

》Power Supply and Automotive Storage Batteries

》Charging station

》LED TV and LED lighting fixtures

》RDRAM memory module

》Miniature heat pipe radiator

》Wireless charging

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2