Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

With the improvement of the performance and functionality of electronic devices, the heat generated by each device increases, and it is important to effectively dissipate, dissipate, and cool the heat. For high-performance mobile products such as 5G smartphones and AR/VR devices, the installation space of heat dissipation components is limited due to the use of high-performance ICs and highly integrated designs that pursue weight reduction. The installation space inside the shell is limited, so TIM technology solutions such as high thermal conductivity gaskets are used to better achieve heat dissipation.

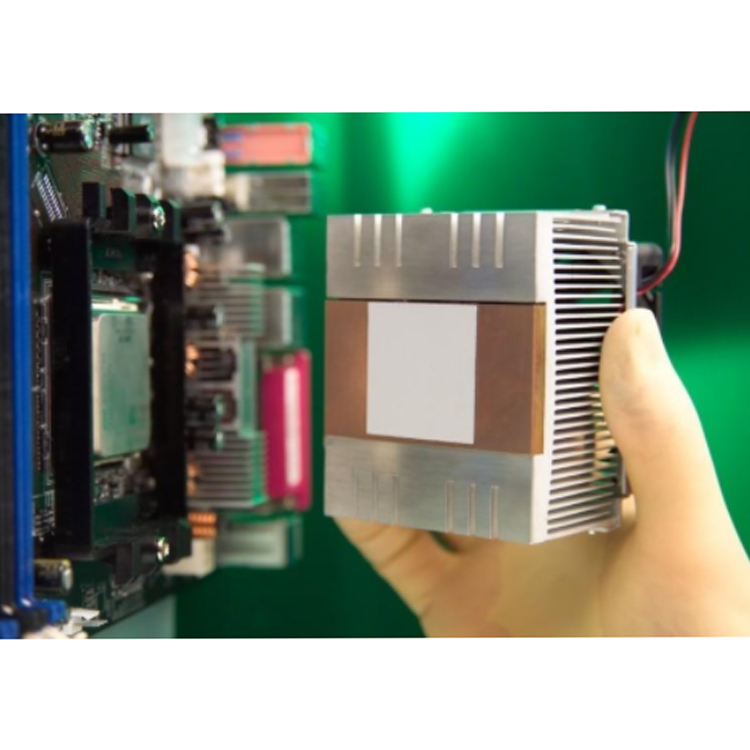

Thermal padIt fills the air gap between the heating element and the heat sink or metal base, and their flexible and elastic characteristics make them suitable for covering very uneven surfaces. Heat is conducted from the separation device or the entire PCB to the metal casing or diffusion board, thereby improving the efficiency and service life of the heat generating electronic components. The thermal pad is installed between the heat dissipation cold plate and the heating chip, which conducts the heat generated by the chip to the heat dissipation cold plate, thereby reducing the temperature of the chip. When the thermal pad is compressed, it will generate compressive stress, which increases with the increase of compression amount. When selecting the thermal pad, it should be noted that the compressive stress during compression should not exceed the maximum required pressure of the heating chip, otherwise it will cause damage to the chip.

In the era of 5G, the functional requirements for electronic products are becoming increasingly high, and more stringent requirements are also put forward for thermal conductivity and heat dissipation systems. Many manufacturers and material manufacturers are seeking materials with higher thermal conductivity, and carbon fiber thermal conductive sheets are gradually being developed and introduced into the market. Carbon fiber thermal conductive sheet is a type of thermal insulation sheet mainly filled with thermal conductive carbon fiber, used between heating components and heat sinks. By filling the gap between the two with air, the heat of electronic devices is accelerated, thereby ensuring the performance and lifespan of electronic products.Thermal conductive carbon fiberIt is a high thermal conductivity carbon fiber material with a thermal conductivity coefficient in the fiber direction that can exceed that of copper. It also has good mechanical properties and excellent thermal and radiation heat dissipation capabilities. The fibrous high thermal conductivity carbon powder made of this carbon fiber itself is fibrous and can be designed with thermal conductivity orientation, which is the biggest difference and advantage from previous thermal conductivity materials.

Compared with the commonly used thermal conductive silicone gaskets in the market,Carbon fiber thermal padSignificant breakthroughs have been made in key parameters such as thermal resistance, thermal conductivity, usability, flame retardant rating, and gasket life, which are commonly used in the cooling system of portable electronic devices. Carbon fiber thermal pads, due to their ultra-high thermal conductivity, light weight, corrosion resistance, high modulus, low density, oxidation resistance, high temperature resistance in non oxidizing environments, reusability, no silicone oil precipitation, dry and non sticky properties, and easy construction, are suitable for various equipment components with high heat density and high dimensional accuracy requirements. They are irreplaceable important components of the heat dissipation system and have a disruptive driving effect on reducing the production cost of cutting-edge equipment and promoting technological innovation in high-tech electronic products.

·Aerospace, military, and automotive electronic cooling and heating components, such as electronic devices, semiconductor memory devices, etc;

·Universal frequency converters, medical equipment DSC;

·Automotive electronics, such as in car cameras, motor control units, car navigation, and car lighting (LED);

·Laser HUD light source;

·3C consumer goods and handheld electronic devices (such as mobile phones, tablets, computers, AR/VR, etc.);

·Base station, chassis, IGBT module.

When designing a thermal pad, many factors need to be considered, such as the chip, cooling plate, thermal pad, and printed board. Therefore, when designing a thermal pad, comprehensive consideration should be given. Generally, the thermal pad can be designed according to the following methods:

Search the chip manual to obtain the maximum allowable pressure of the chip;

Selection of thermal pad, determining the type and thermal conductivity of the selected thermal pad, and obtaining the compressive stress curve of the thermal pad;

Based on the maximum allowable pressure value of the chip and the compression stress curve of the thermal pad, obtain the maximum compression rate of the thermal pad;

Based on the maximum compression rate of the thermal pad, select the thickness of the thermal pad to obtain the reserved gap value of the thermal pad. The recommended compression rate of the thermal pad is not less than 25%;

Design the size of the heat dissipation plate based on the reserved gap value of the thermal pad, taking care to avoid cumulative errors and warping deformation;

Calculate the range of height variation after chip soldering based on the thickness tolerance of the chip and the workshop processing level, divide the range of height variation after chip soldering into intervals, and select different thicknesses of thermal pads according to different intervals.

The current situation of carbon fiber thermal pads on the market (it is said that foreign brands are the main ones, and new manufacturers are constantly entering and will continue to be closely monitored)

·Thickness: 0.3~3.0mm

·Low density: around 2.6 g/cm ³

·Thermal interface performance: 10~40W/(m · K)

·Good flexibility: can be perfectly embedded into uneven interfaces

·Suitable operating temperature: -40~150 ℃ to maintain stable performance

·Flame retardant performance: meets UL94-V0 level

·Environmentally friendly products comply with RoHS REACH

Advanced Institute (Shenzhen) Technology Co., LtdEstablished in Shenzhen, the central city of the Guangdong Hong Kong Macao Greater Bay Area, we focus on integrating high-end raw material resources and providing comprehensive new material application solutions to create maximum value for our customers. Shielding absorbing, conductive, sealing, and heat-conducting materials are mainly used in market fields such as electronic consumption, 3C home appliances, artificial intelligence, and medical equipment.

With the development of new industries such as 5G, semiconductors, and new energy, we actively develop innovative materials that meet emerging needs, constantly meet the challenges of customers in various industries, and continuously provide innovative new material services to keep customers flexible and competitive when market demand changes. Innovation and technology are derived in parallel, and this powerful wave of vitality is driving Advanced Institute (Shenzhen) Technology Co., Ltd. towards becoming a world-class material solution provider.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2