Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

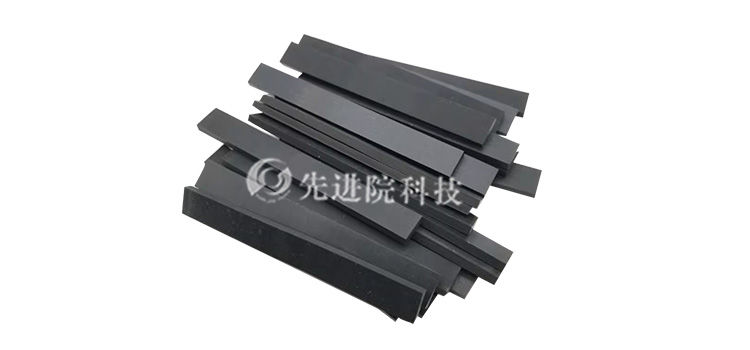

Mold pressing and die-cutting square liners are two distinct manufacturing processes. The molding process is suitable for mass production of high-precision and high-density square cushion products; The die-cutting process is more flexible and versatile, suitable for small and medium-sized production of various shapes of cushion products. Choosing the appropriate manufacturing process based on specific application scenarios and requirements is key to ensuring product quality and production efficiency.Specifications can be customized according to specific needs. Welcome to call for consultation.

+86-13826586185

For molded square pads, their hardness needs to be adjusted according to specific application scenarios. If it is used for parts that can withstand high pressure, higher hardness may be required; If it is a pad used for buffering and protecting precision components, it requires lower hardness.

Elasticity is also an important performance indicator. Good elasticity can ensure that the pad can return to its original shape after being subjected to pressure, thereby continuously exerting its buffering and supporting effects.

In addition, wear resistance and corrosion resistance are also crucial in some application scenarios. For example, square pads in outdoor or chemical equipment need to be able to resist the erosion of environmental factors.

Dimensional accuracy is a key requirement for die-cutting square liners. Especially in applications that require high assembly accuracy, such as electronic product packaging, the size of square pads must be precise to ensure a good match with the product and packaging box.

The strength of the material is also a factor that needs to be considered. For some square cushions that require a certain amount of pressure or friction, such as cushions in furniture, the material needs to have sufficient strength to prevent cracking or deformation during use.

If it is in special application scenarios such as food packaging, the material of square liners also needs to meet food safety standards and have characteristics such as non-toxic and odorless.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2