Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

+86-13826586185

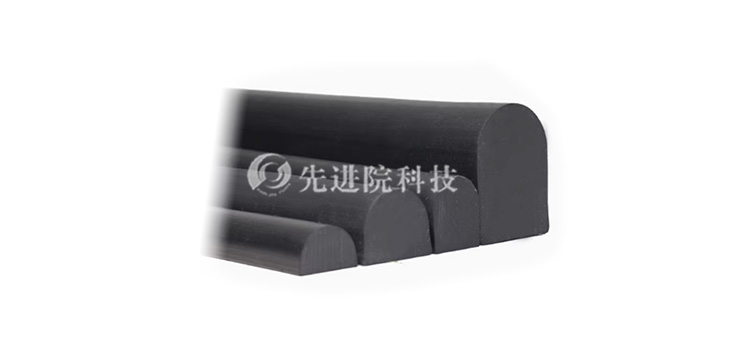

Conductivity: The uniformly distributed conductive particles inside the D-type solid conductive rubber strip ensure its excellent conductivity, which can play a role in conductive connection in electrical equipment and ensure the normal transmission of current.

Sealing performance: Its soft sealing performance can effectively fill and seal the gaps between equipment, preventing dust, moisture, and other harmful substances from entering the interior of the equipment, playing a role in dust, water, and corrosion prevention.

Insulation performance: In addition to conductivity, D-type solid conductive rubber strips also have good insulation performance, which can prevent current leakage or short circuit to a certain extent, and protect the safety of equipment and personnel.

Durability: The D-type solid conductive rubber strip made of conductive silicone rubber has excellent heat resistance, aging resistance, oil resistance, and chemical corrosion resistance, and can be used for a long time in harsh working environments, extending the life of electrical equipment.

Customizability: D-type solid conductive rubber strips can be designed with specific product cross-sections and length dimensions according to the customer's usage environment to meet the needs of different fields and occasions.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2