Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

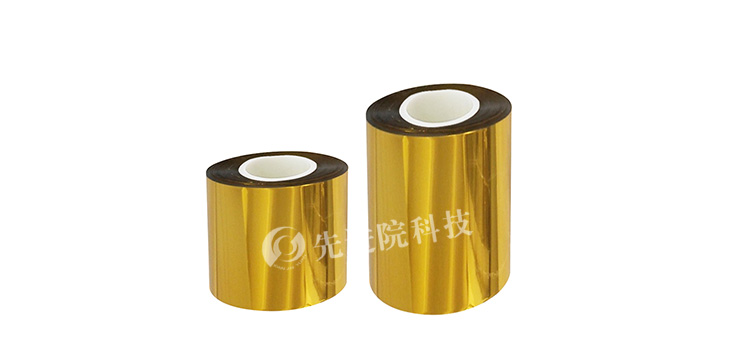

Ceramic gold plating, as an advanced material, combines the high strength of ceramics with the good conductivity of gold, possessing excellent corrosion resistance and aesthetics. Widely used in fields such as electronics, decoration, aerospace, and medical equipment, it enhances the reliability and functionality of products. Its environmentally friendly and sustainable characteristics also make it have broad application prospects in the future.Advanced Institute of TechnologyCeramic gold plating, can be customized in size and thickness according to needs; Welcome to consult.

+86-13826586185

陶瓷镀金是一种先进的表面处理技术,通过物理气相沉积(PVD)等方法在陶瓷基体表面镀上一层金。这种工艺不仅保留了陶瓷的高强度和耐高温性,还赋予了其金层的导电性和美观性。金层通过过渡层(如铬层或镍层)与陶瓷基体紧密结合,形成一个整体。金层具有纯金色泽、细腻光滑,兼具优异的导电性和耐腐蚀性。陶瓷镀金广泛应用于电子、装饰、航空航天及医疗器械等多个领域。

特性

高导电性:金层具有良好的导电性能,适用于多种电气和电子应用。

耐腐蚀性:金层能够有效防止陶瓷表面的氧化和腐蚀,延长产品的使用寿命。

美观性:金层色泽纯正、细腻光滑,提升了产品的装饰效果。

耐磨性:金层与陶瓷基体结合牢固,不易磨损脱落,适用于多种环境。

环保性:生产过程中无污染,符合环保要求。

产品优势

多功能性:陶瓷镀金产品结合了陶瓷的高强度和金的导电性,适用于多种应用场景。

高可靠性:在恶劣环境条件下仍能保持稳定的性能,适用于高要求的应用场景。

加工便捷:可通过多种方式加工,满足不同产品的制造需求。

环保可持续:材料可回收再利用,符合环保可持续发展要求。

工艺

物理气相沉积(PVD):通过磁控溅射、多弧离子镀或电子枪蒸发等方法,在陶瓷表面沉积一层金。

过渡层:在陶瓷基体与金层之间设置过渡层(如铬层或镍层),以增强附着力。

表面处理:经过精细打磨和平整处理,确保金层表面平整光滑。

车间展示

Advanced Institute Technology Ceramic Gold Plating can be customized to various sizes and thicknesses as needed

Ceramic magnetron sputtering gold plating is a commonly used surface treatment technique, which forms a layer of gold plating film on the surface of ceramic materials to improve their aesthetics, corrosion resistance, and conductivity.

1. Process principle:

Ceramic magnetron sputtering gold plating is a process that utilizes the principle of magnetron sputtering. In a vacuum environment, a certain electric field is applied between the metal target and the ceramic material reaction chamber to accelerate the impact of metal particles on the ceramic surface, forming a thin metal film. This type of film can protect the surface, increase gloss and aesthetics, and have excellent conductivity.

2. Advantages:

Ceramic magnetron sputtering gold plating can form a uniform and dense metal film on the surface of ceramics, with good adhesion and corrosion resistance, which can effectively protect the surface of ceramic materials from damage. At the same time, metal films can improve the conductivity of ceramics and have a certain degree of thermal conductivity, which is beneficial for the use of ceramic materials in special environments.

3. Precautions:

When conducting ceramic magnetron sputtering gold plating, it is necessary to fully consider the physical properties and shape of the ceramic material. Ceramics of different materials and shapes have varying requirements for sputtering process parameters and gold plating effects. In addition, when preparing metal target materials, it is important to ensure their purity and uniformity in order to achieve better sputtering gold plating effects.

4. Application areas:

Ceramic magnetron sputtering gold plating is widely used in medical products, communication products, aerospace and other fields. By gold plating treatment, ceramic materials can increase their market competitiveness.

In summary, ceramic magnetron sputtering gold plating is a commonly used surface treatment technique with advantages such as uniform coating and corrosion resistance, which is suitable for fields such as medical, communication, aerospace, etc. When carrying out this process, it is necessary to pay attention to the characteristics and shape of the ceramic material in order to achieve better gold plating effect.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2